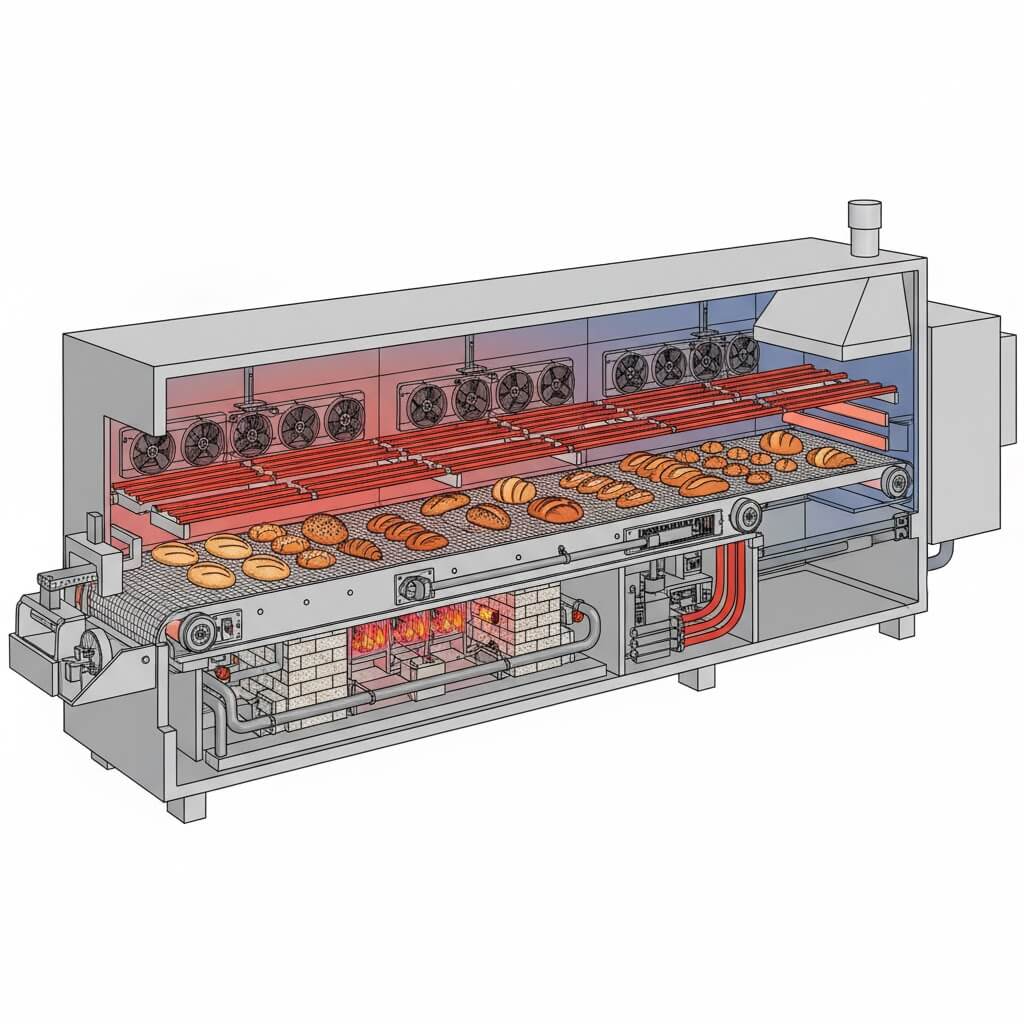

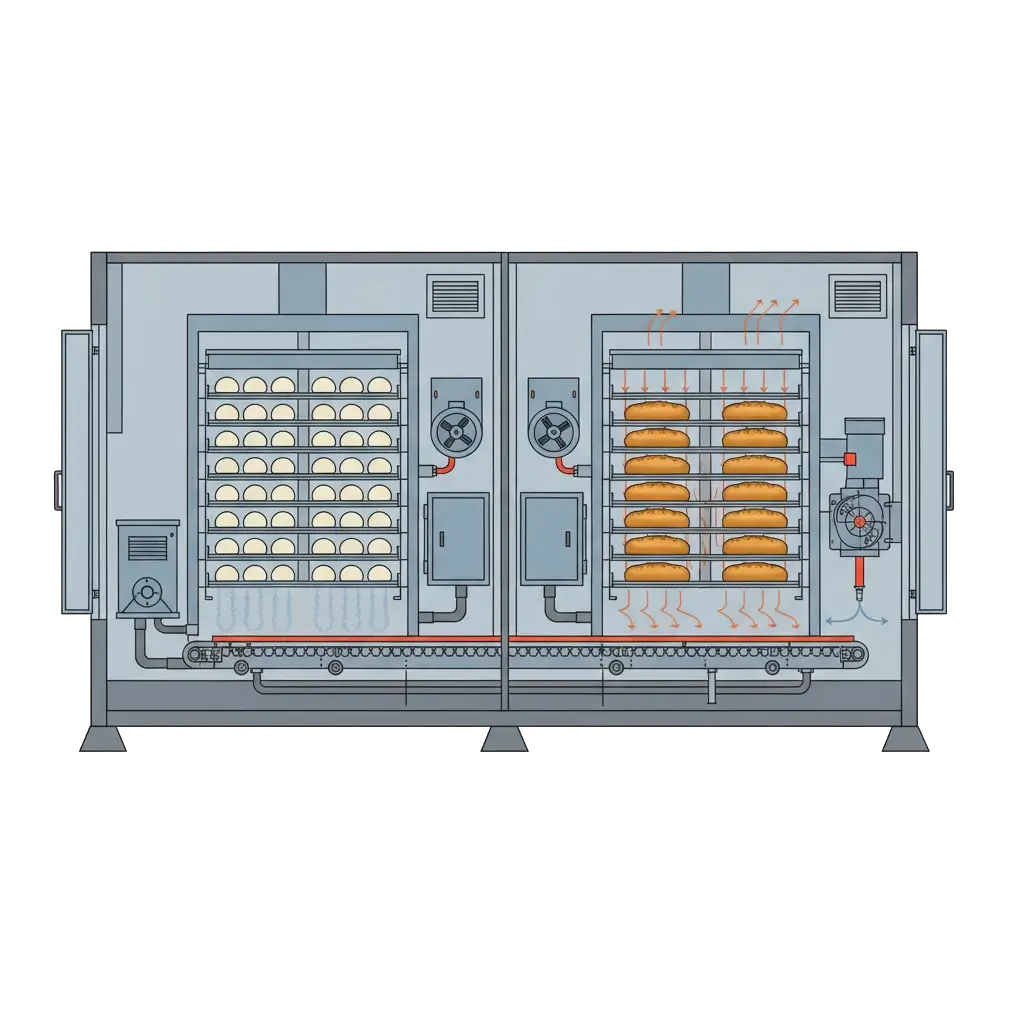

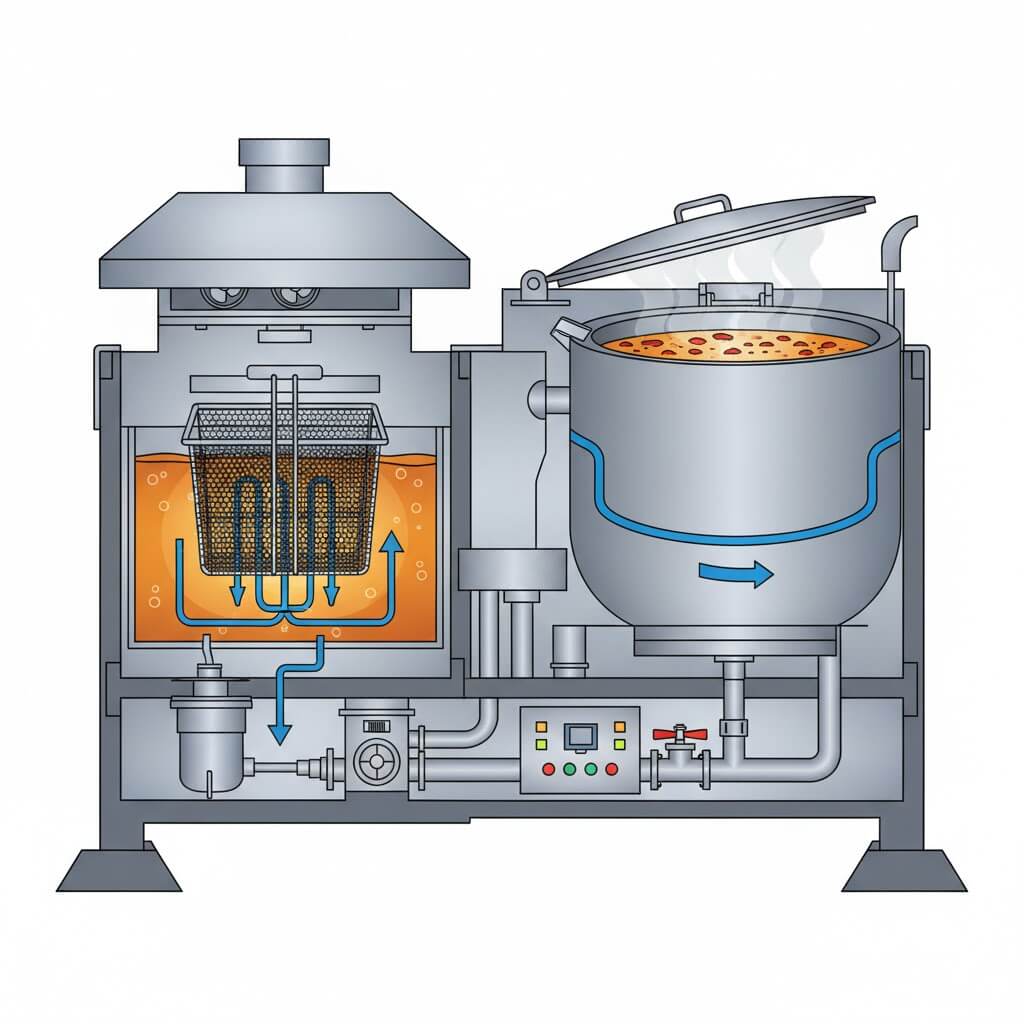

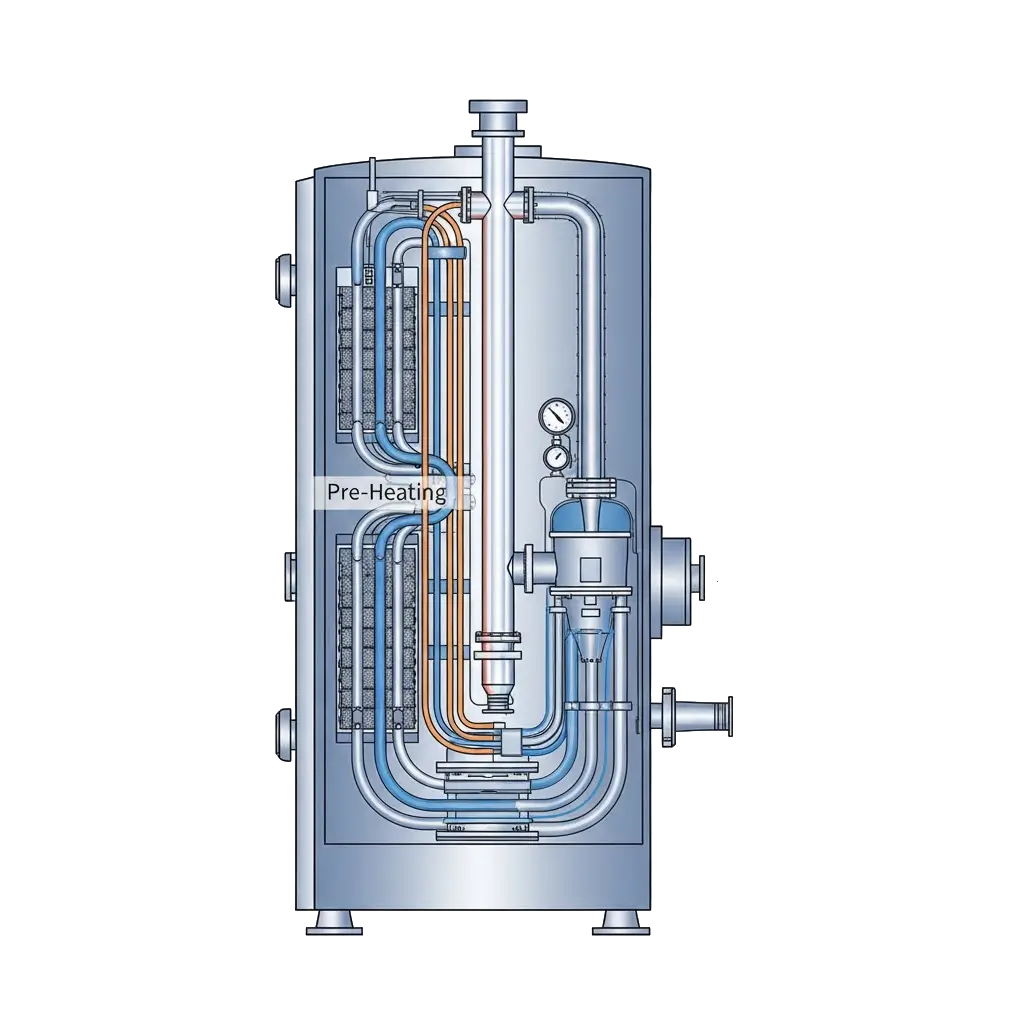

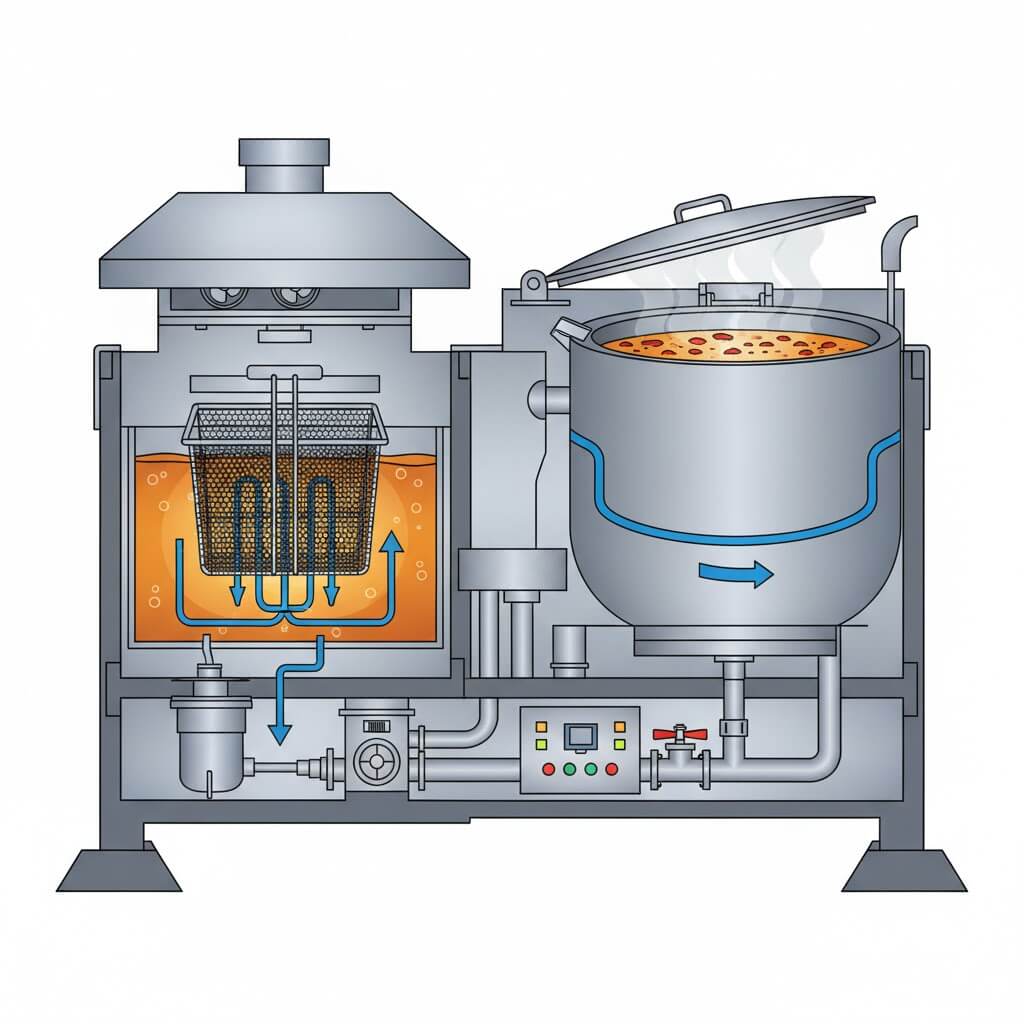

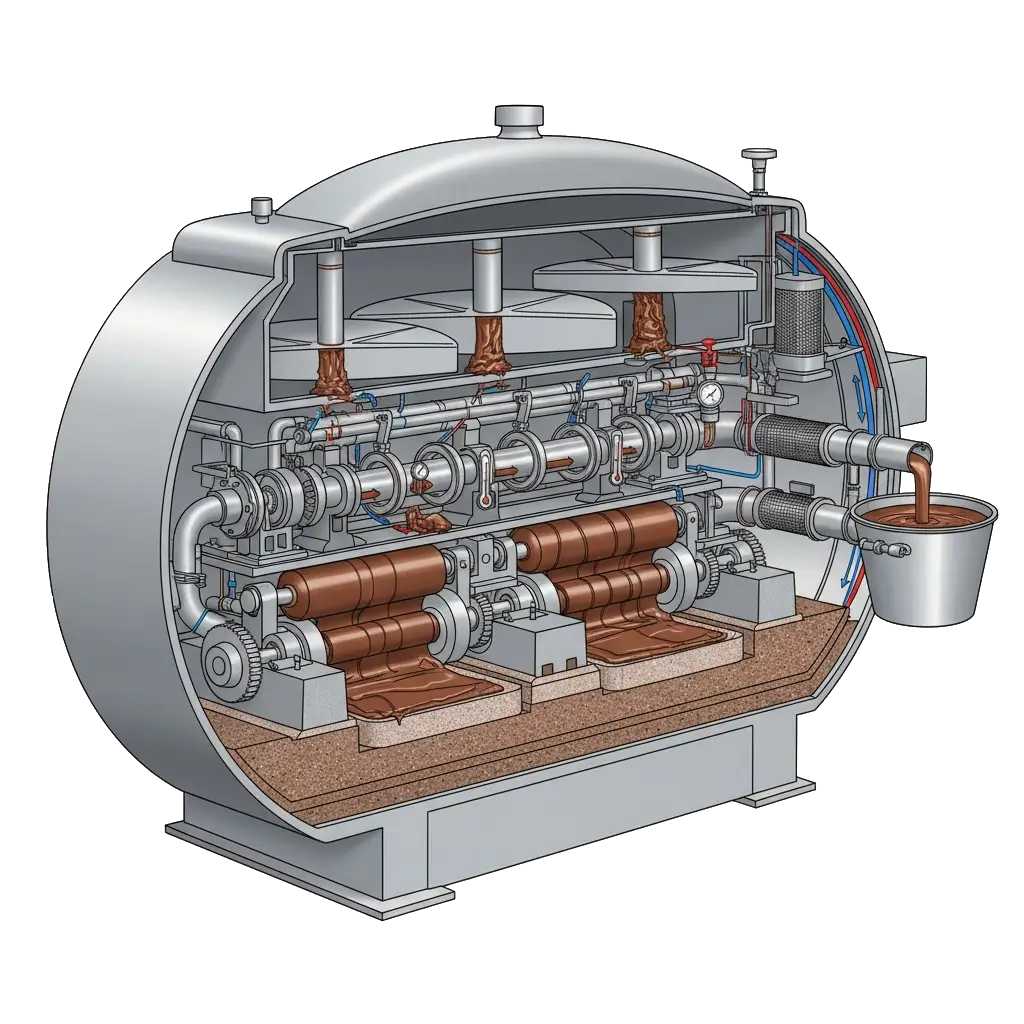

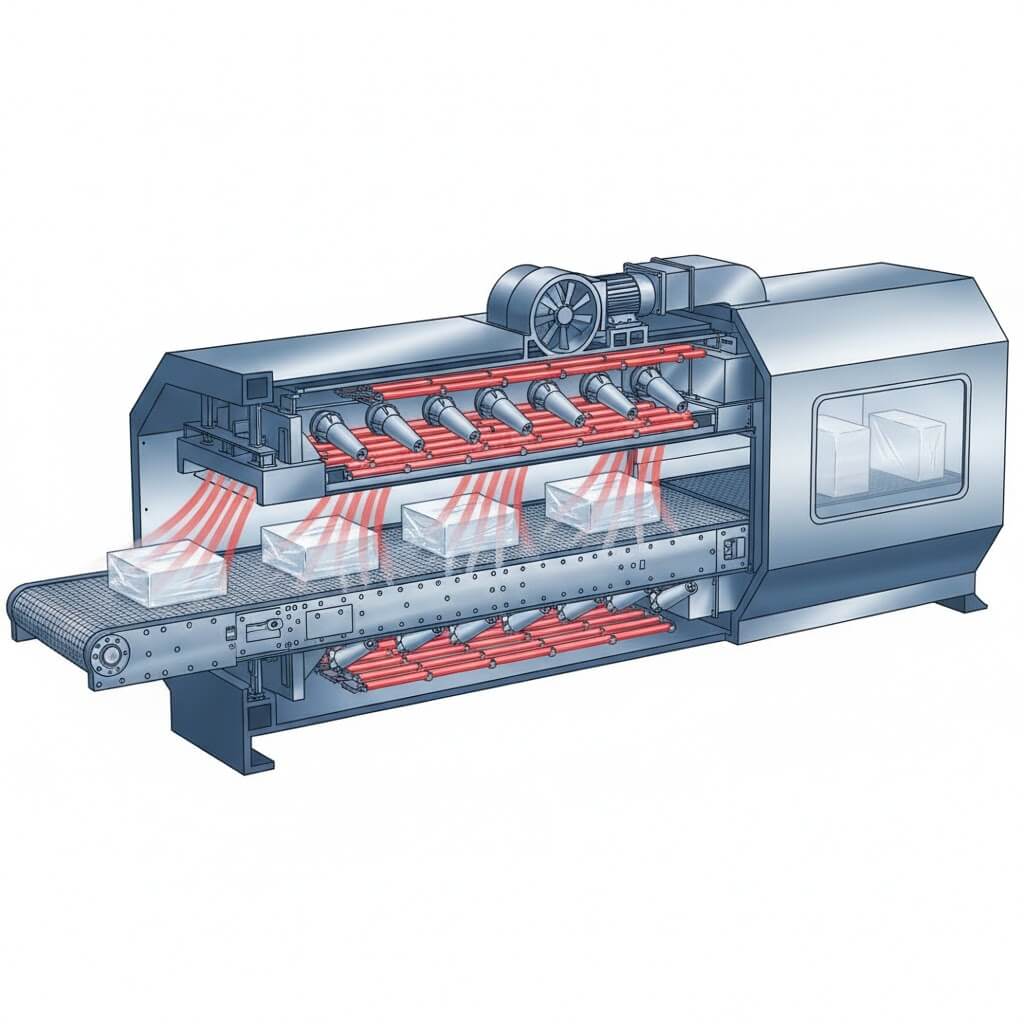

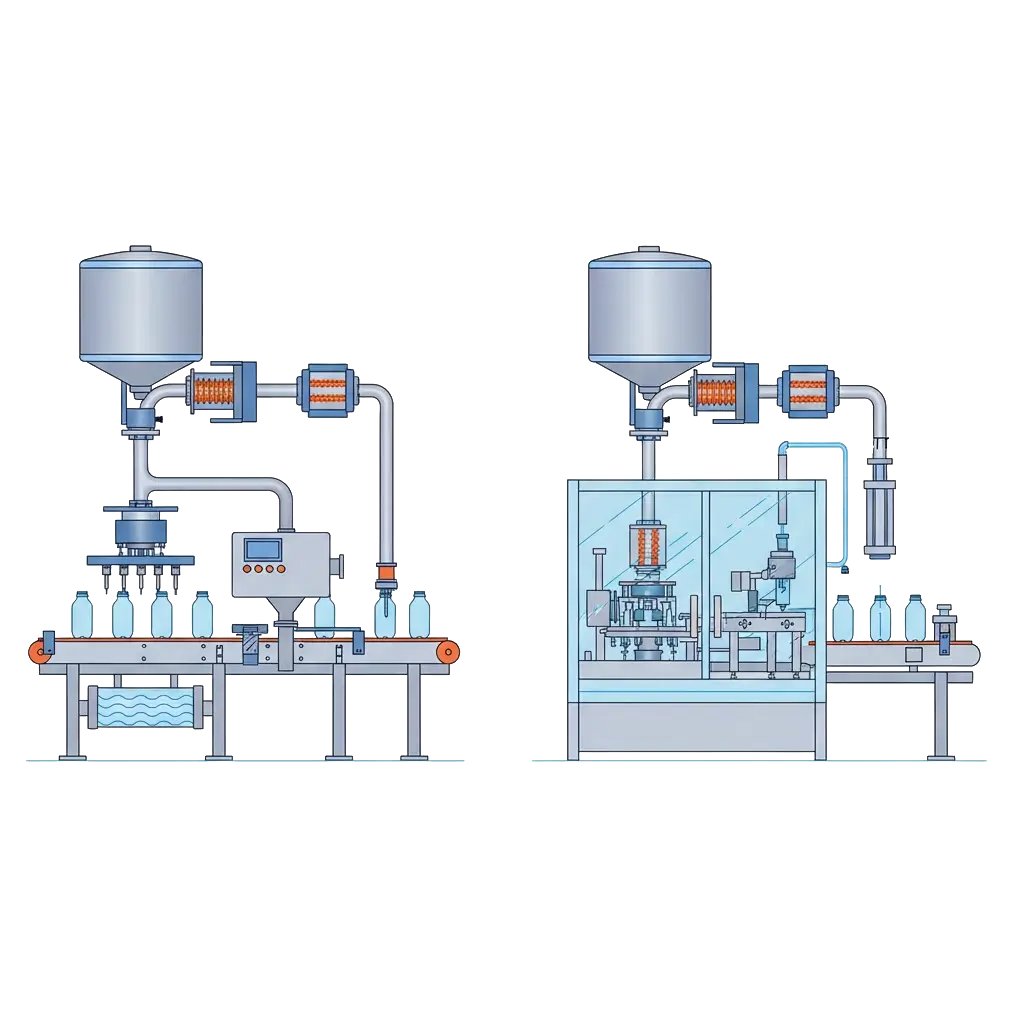

CD Automation supplies SCR/thyristor power control for food and drink processes including baking and tunnel ovens, proofers, fryers and kettles, pasteurisers/UHT systems, CIP/SIP heaters, chocolate tempering and packaging shrink tunnels. REVO controllers help improve product consistency, support hygiene-focused designs and provide useful diagnostic and energy data to plant automation systems.

With REVO C for single zones, REVO-PN for compact multi-zone equipment, and REVO-PC, or REVO-DPU zone control for larger lines and utilities, we integrate with PLC and SCADA platforms using common fieldbuses to support OEMs and end-users across bakery, dairy, beverages, ready meals and confectionery.

Food and drink manufacturers use electric heating in ovens, proofers, fryers, kettles, pasteurisers/UHT systems, CIP/SIP heaters, chocolate lines and packaging equipment. Stable, repeatable temperature control helps maintain product quality, microbiological safety and throughput, while efficient power delivery supports energy and sustainability objectives. Intelligent SCR power control can improve stability, help manage electrical load and provide data to plant automation and monitoring systems.