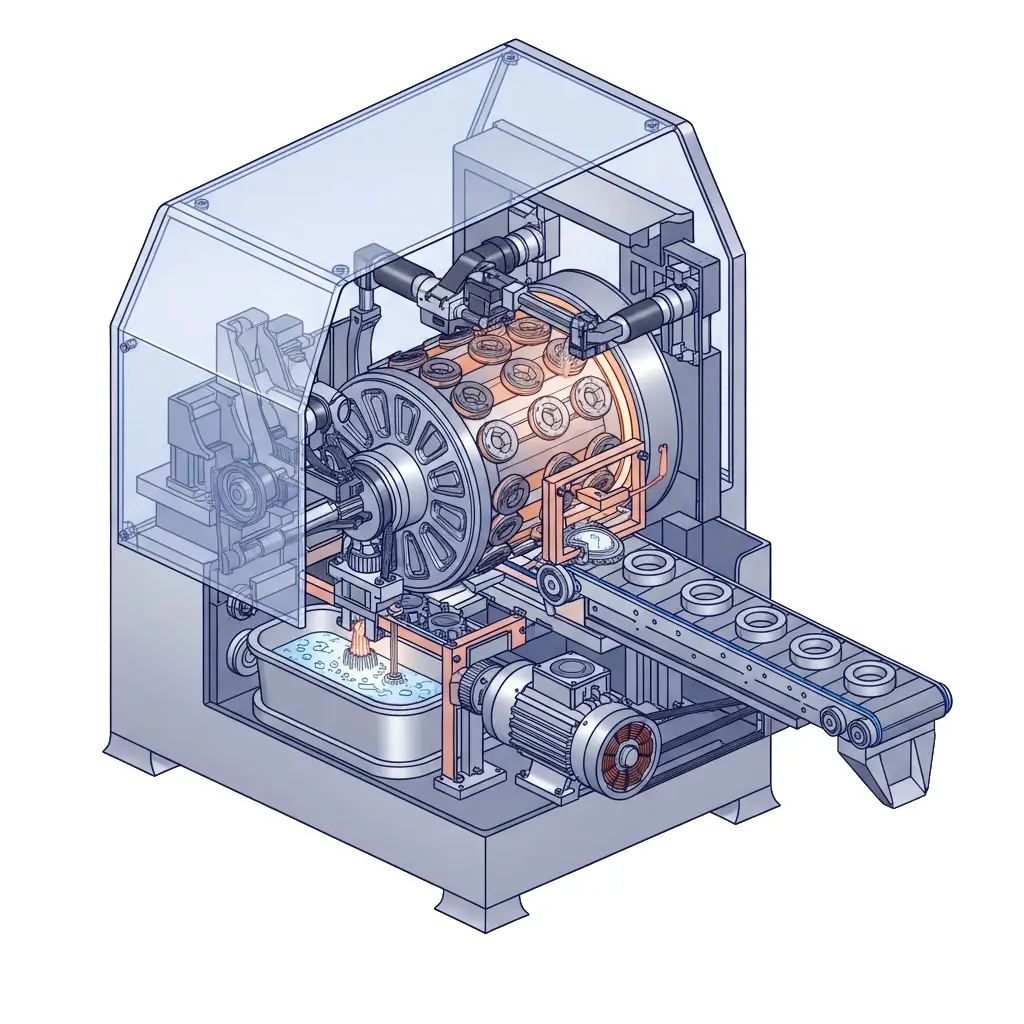

CD Automation supplies SCR/thyristor power control for glass melting, conditioning, forming and finishing -from electric boosting and forehearths to tin baths, annealing lehrs, tempering furnaces and fibre bushings. REVO controllers help stabilise temperature profiles, support higher pull or throughput and provide useful diagnostics and energy data to plant control systems.

With REVO C for single zones, REVO-PN for compact multi-zone equipment, and REVO-PC, or REVO-DPU zone control for larger lines and high-power systems, we integrate with PLC, SCADA and DCS platforms used by OEMs, integrators and end users in flat, container and fibre glass production.

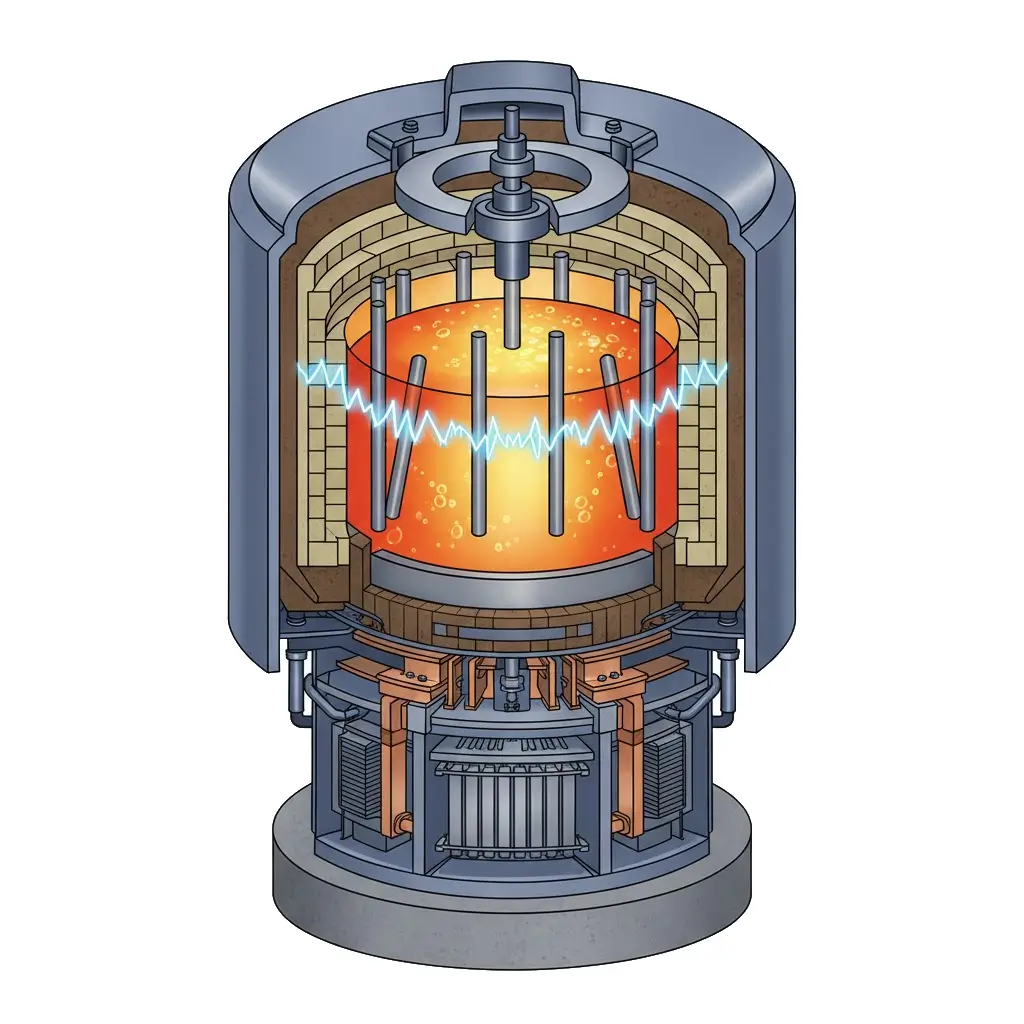

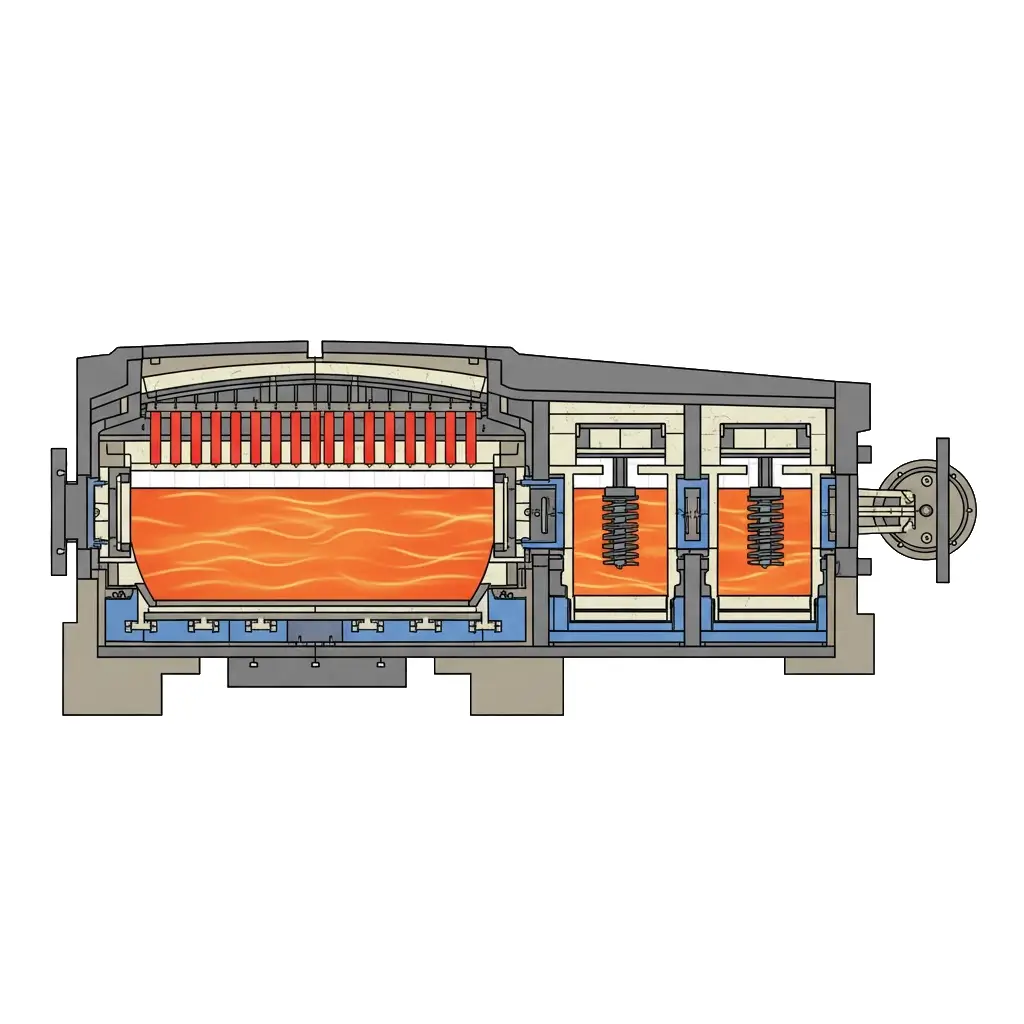

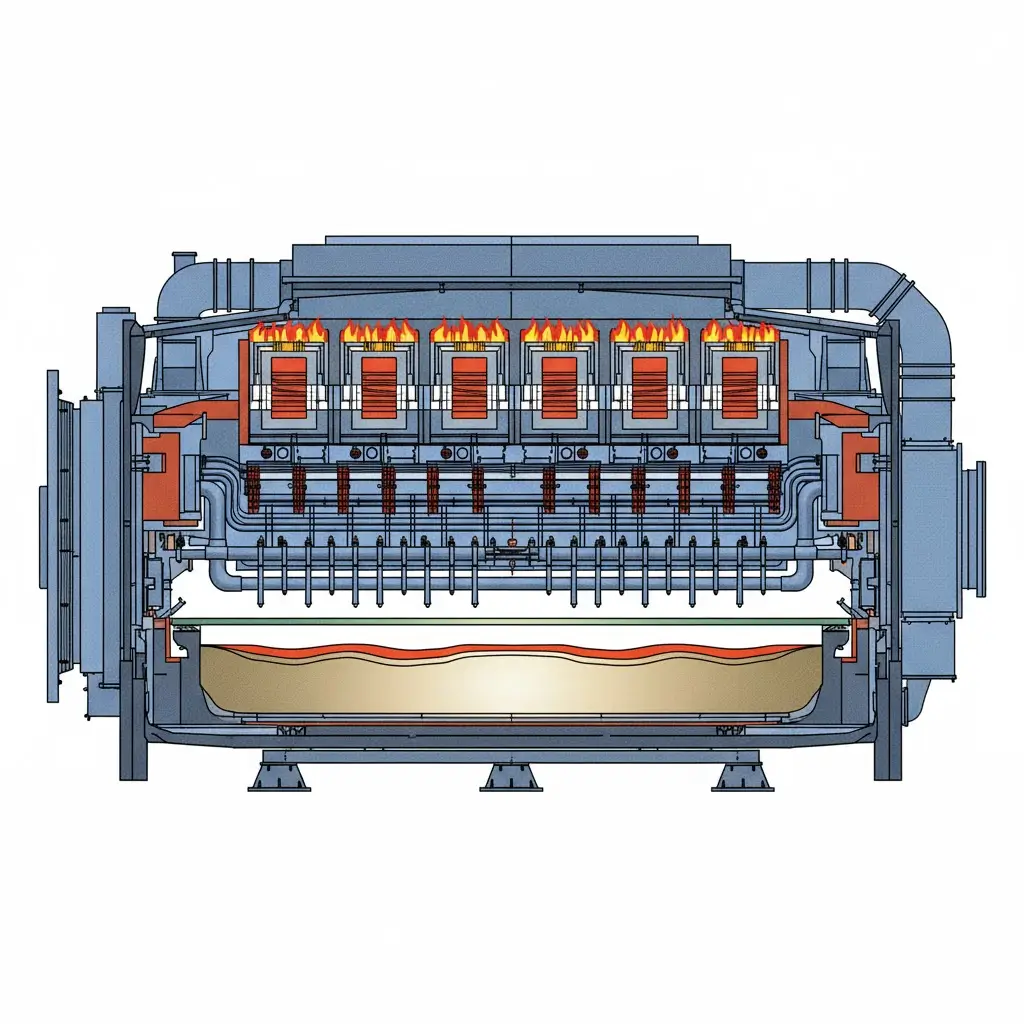

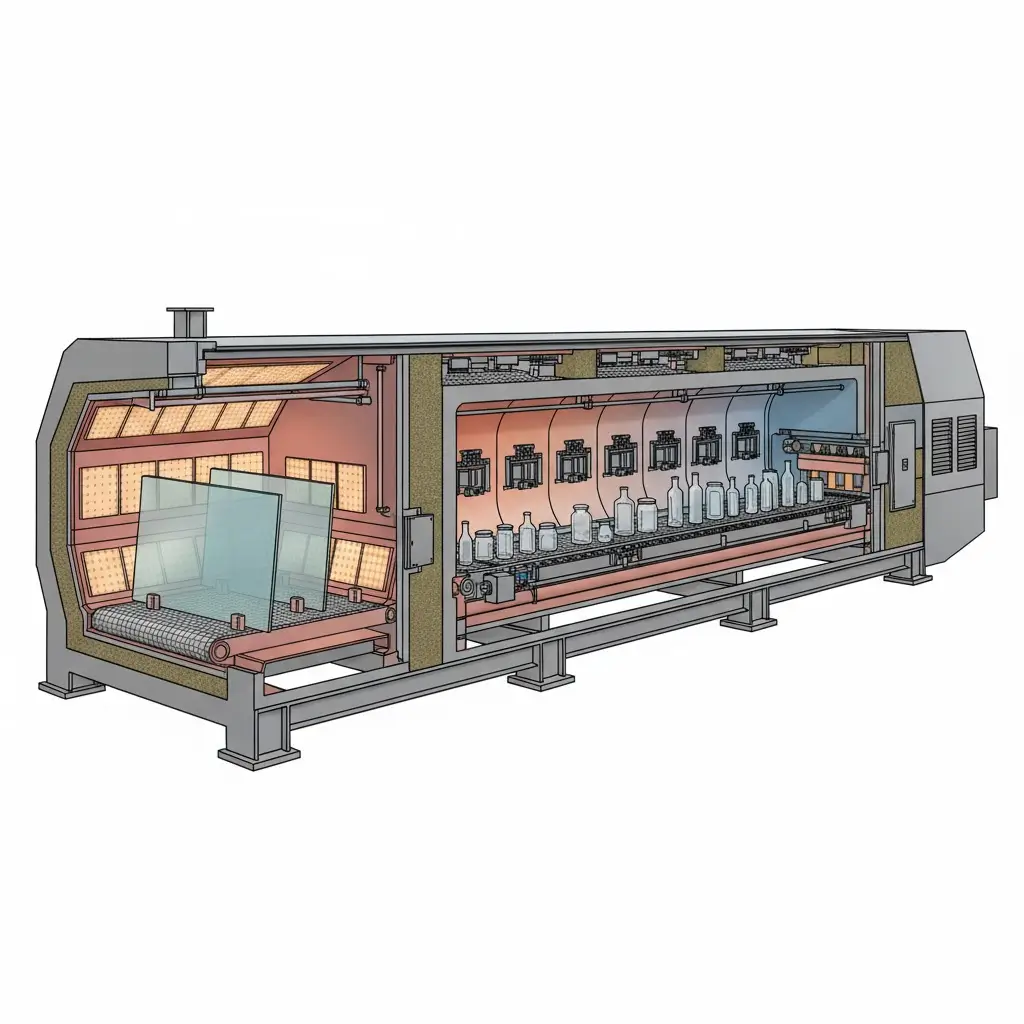

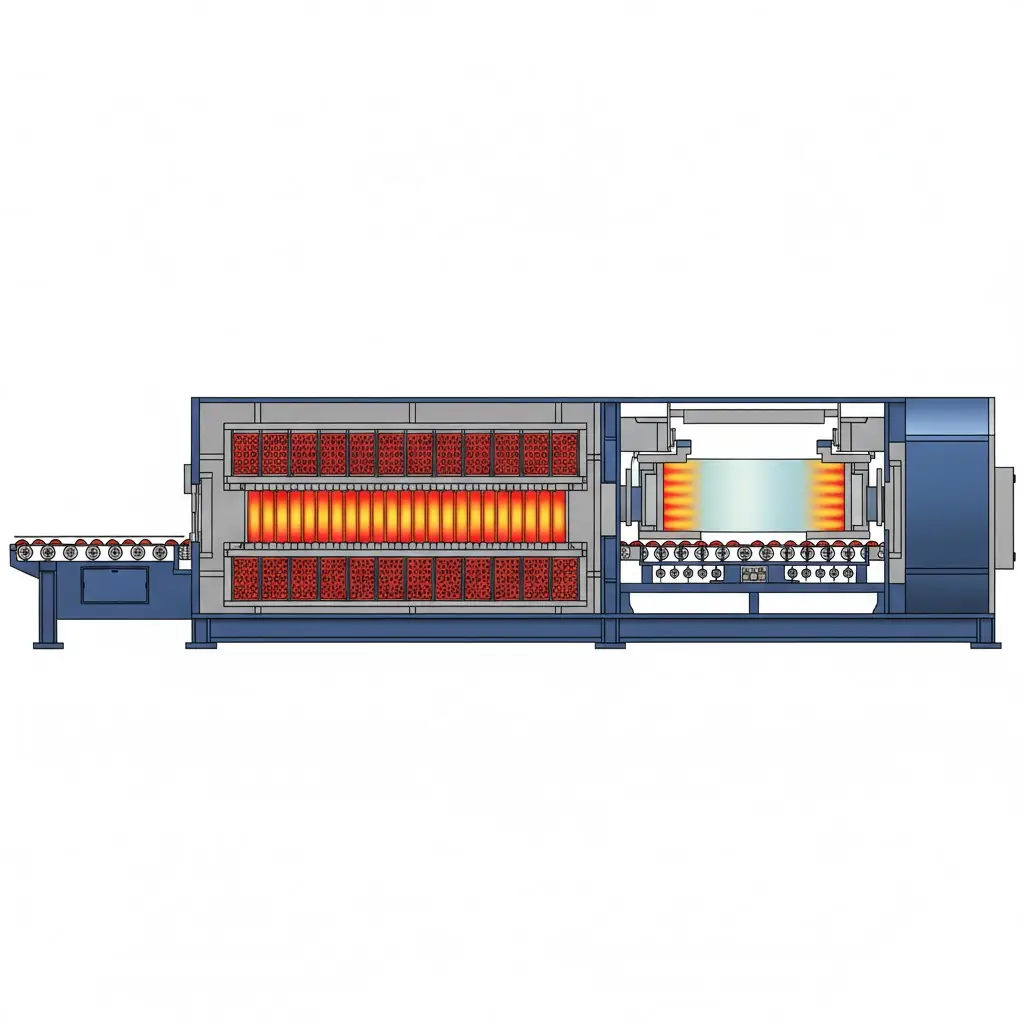

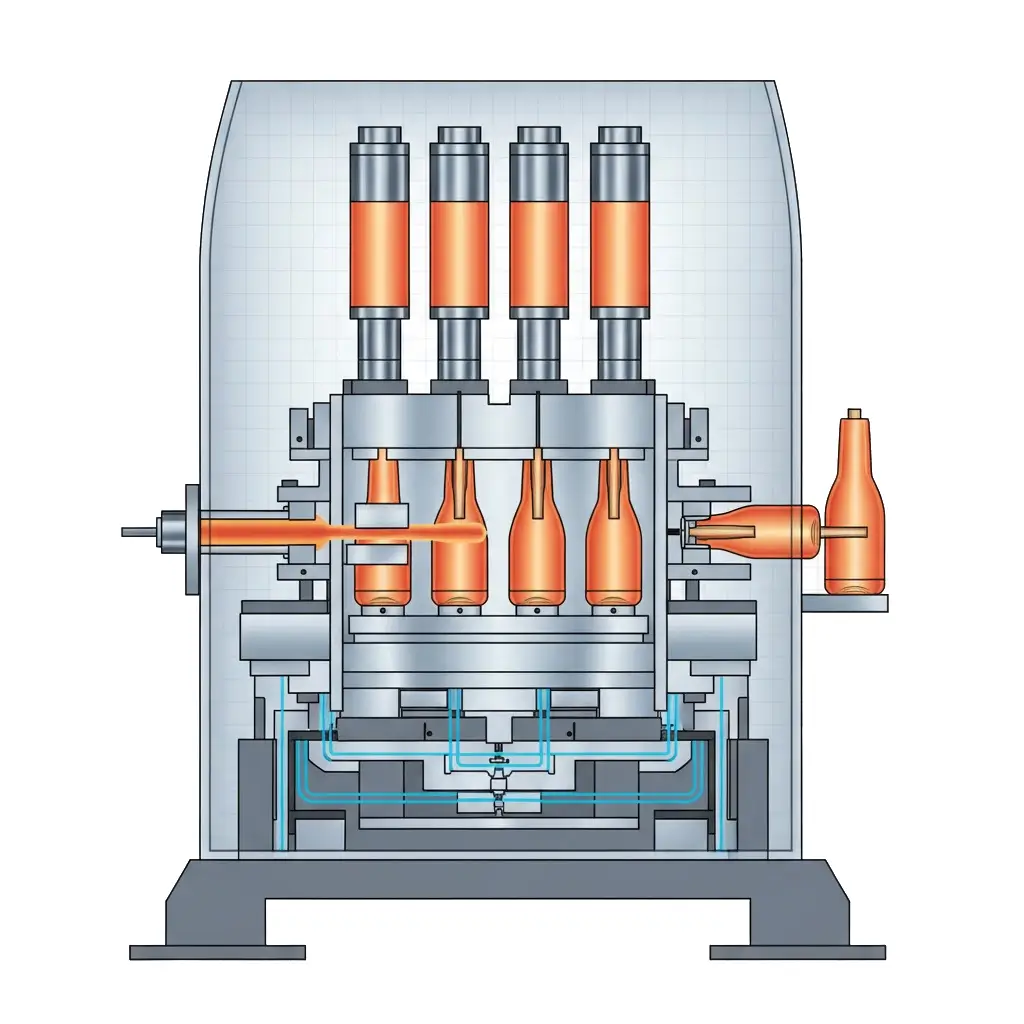

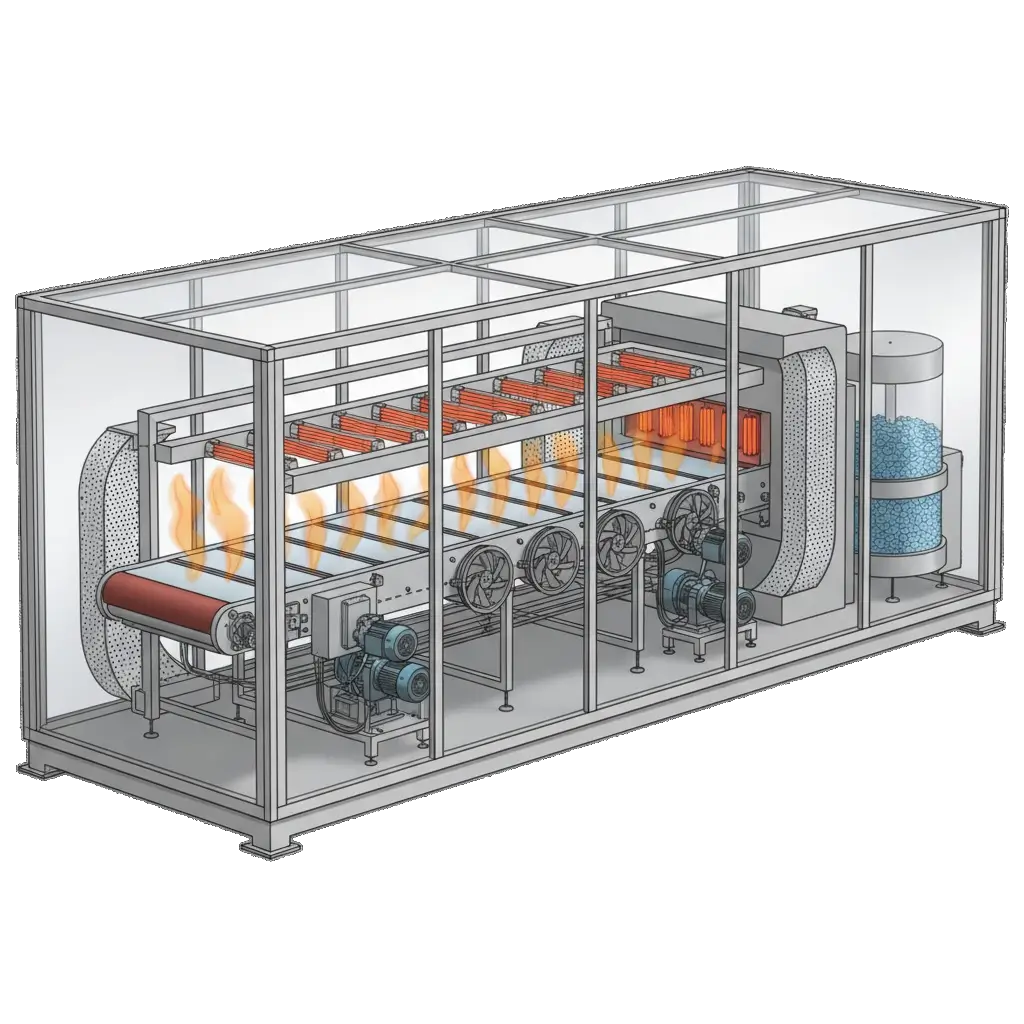

Flat, container and fibre glass operations use electric heating across melting, conditioning, forming and finishing stages. Electric boosting supports furnace output and stability, forehearths condition glass temperature and viscosity, tin baths and lehrs shape flat glass quality, and tempering or coating lines define final performance. Intelligent SCR power control can improve temperature and power stability, help manage electrical demand and provide data for process optimisation and maintenance.