Precision Power Control for Energy‑Efficient Industrial Heating Systems

We work with UK machinery OEMs to design and supply thyristor power controllers that improve the efficiency, stability, and controllability of electrical heating processes. Through custom engineering and OEM‑focused integration support, we help manufacturers reduce energy losses, lower operating costs, and deliver machines that remain competitive in demanding industrial environments.

CD Automation thyristor power controllers are designed for continuous industrial duty, not intermittent or light-use applications.

Key design considerations include:

The CD Automation range is designed with a target MTBF of 10 years under normal industrial operating conditions.

This long-term reliability is achieved through:

For OEM engineers, this supports:

While low-cost power control solutions may appear attractive initially, they often introduce higher lifetime costs through:

CD Automation controllers are engineered to minimise total cost of ownership by:

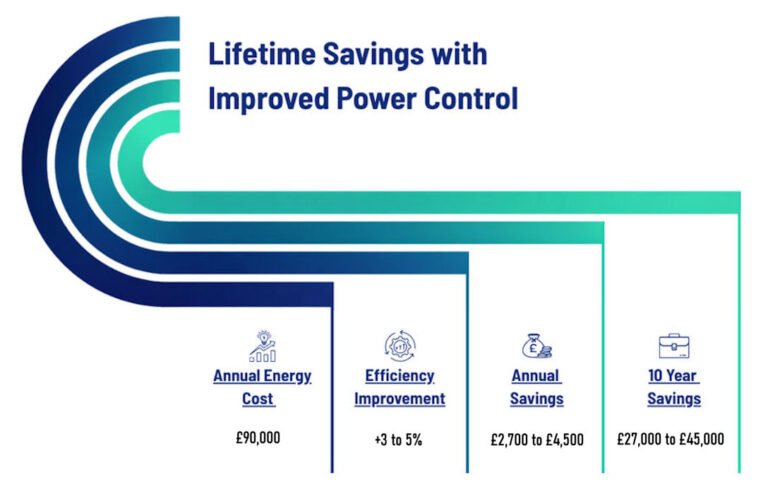

The following example is indicative and provided to support engineering and commercial evaluation.

Annual energy cost: £90,000

A conservative 3–5% efficiency improvement achieved through improved thyristor power control equates to:

These savings are achieved without mechanical redesign and can be validated during factory acceptance testing.

It’s common for OEMs to ask why an industrial-grade thyristor controller costs more than basic alternatives.

The answer is simple: performance over time.

CD Automation controllers are not designed to meet minimum specifications, they are designed to deliver:

For OEMs and their customers, this translates into fewer problems, lower long-term costs, and greater confidence in every machine delivered.

By optimising power delivery rather than simply switching load on/off, OEMs achieve repeatable efficiency gains that can be quantified during factory testing and demonstrated to end customers.

Efficiency becomes an engineered feature, not a marketing claim.

Our solutions are widely used by UK OEMs in: