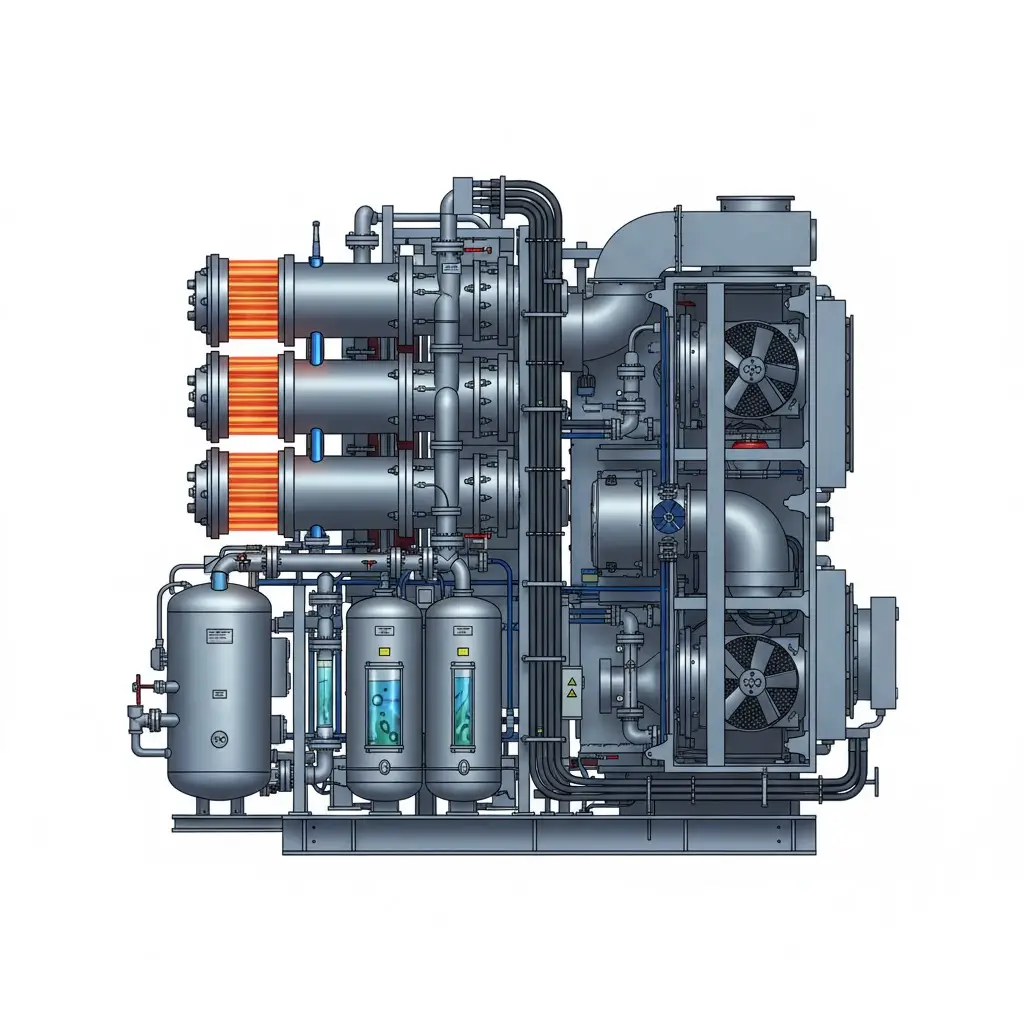

CD Automation provides SCR/thyristor power control for electric heating in oil, gas and petrochemical facilities. From heater skids and reboilers to fuel gas heaters and offshore utilities, our REVO controllers help deliver stable temperature control, smoother electrical loading and the data needed for modern electrification projects.

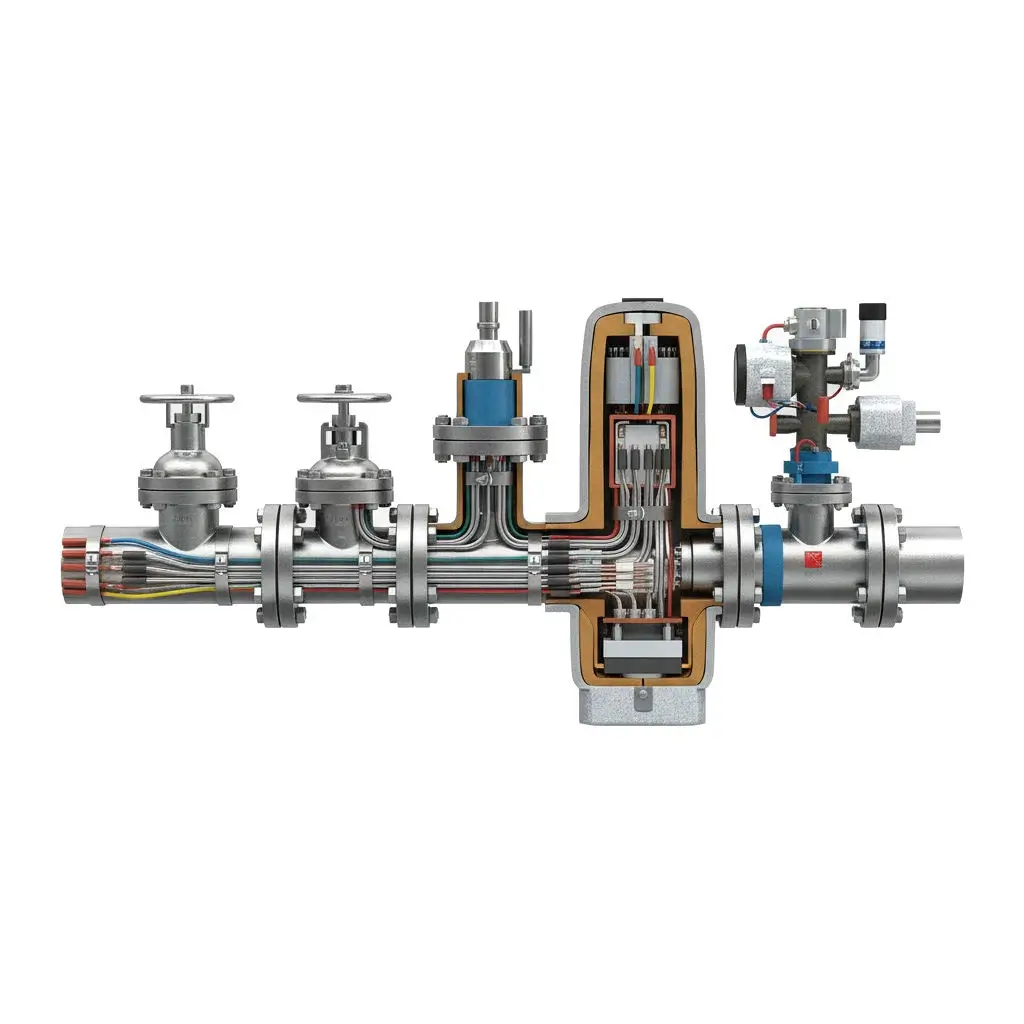

Electric process heating can reduce onsite emissions from combustion systems and improve controllability. With features such as current limiting, appropriate firing modes and fieldbus communications, REVO C, REVO-PN and REVO-PC-based architectures support OEM skid builders and operating companies in demanding environments.

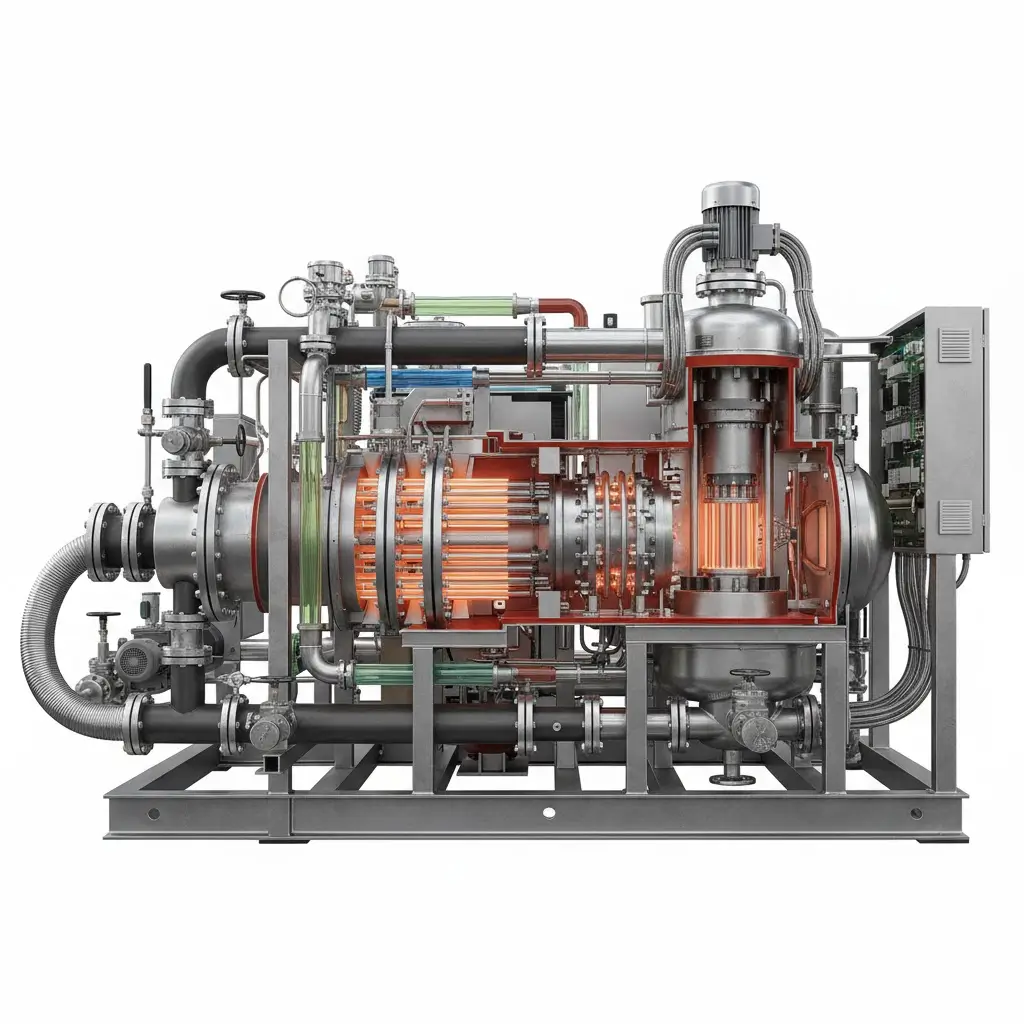

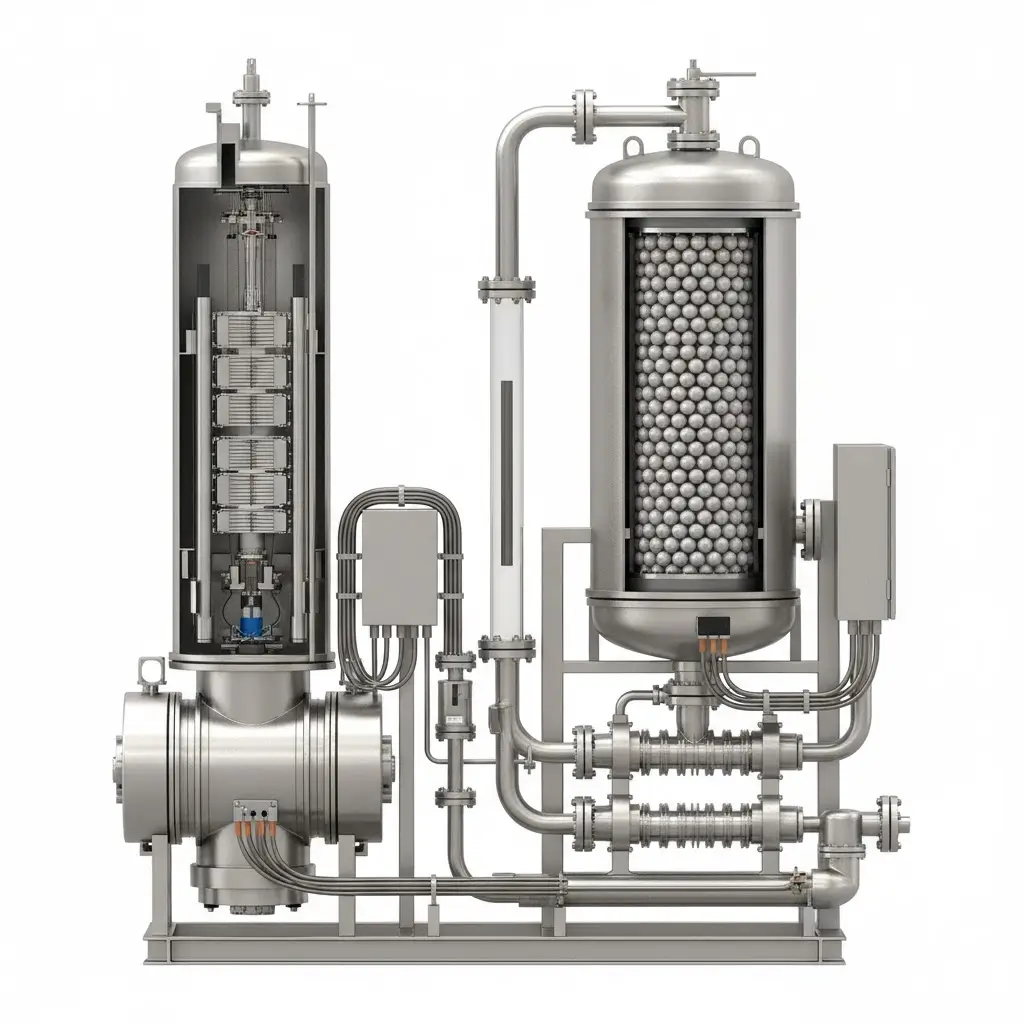

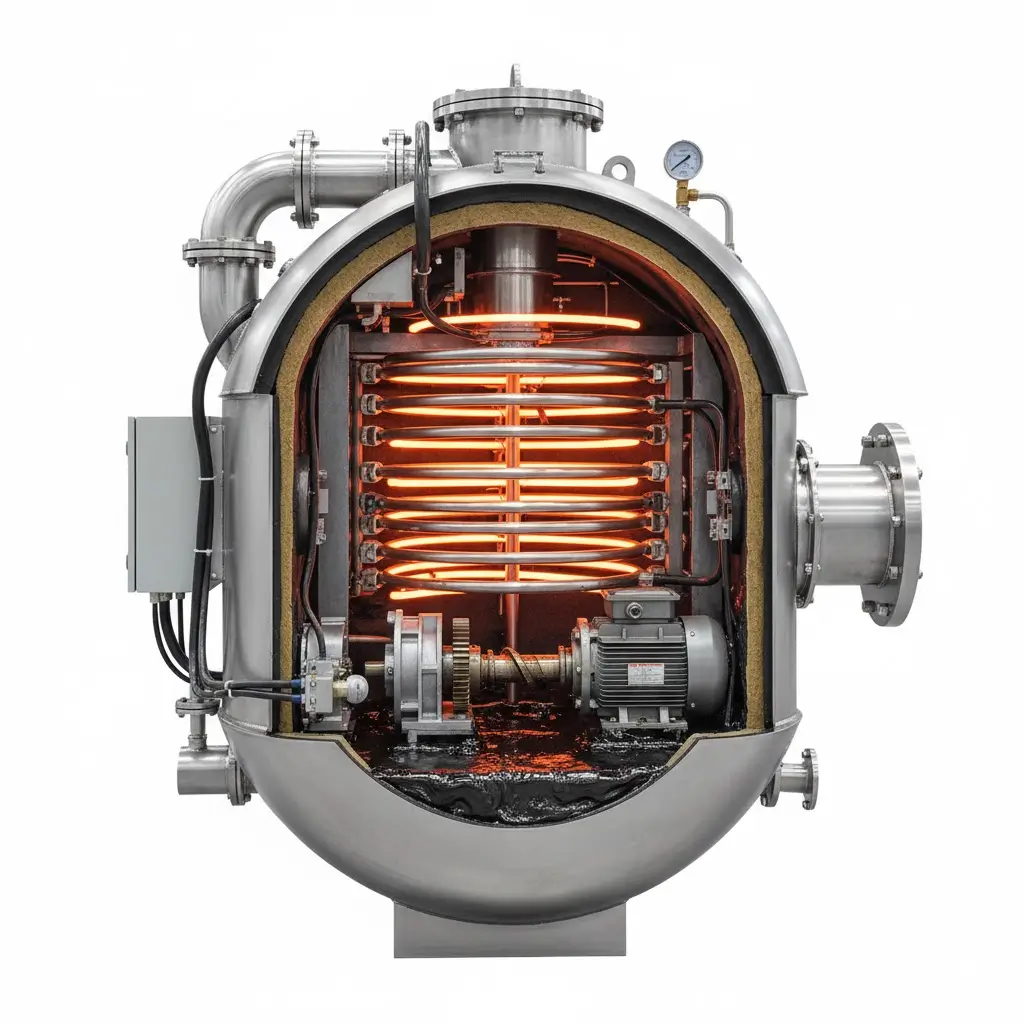

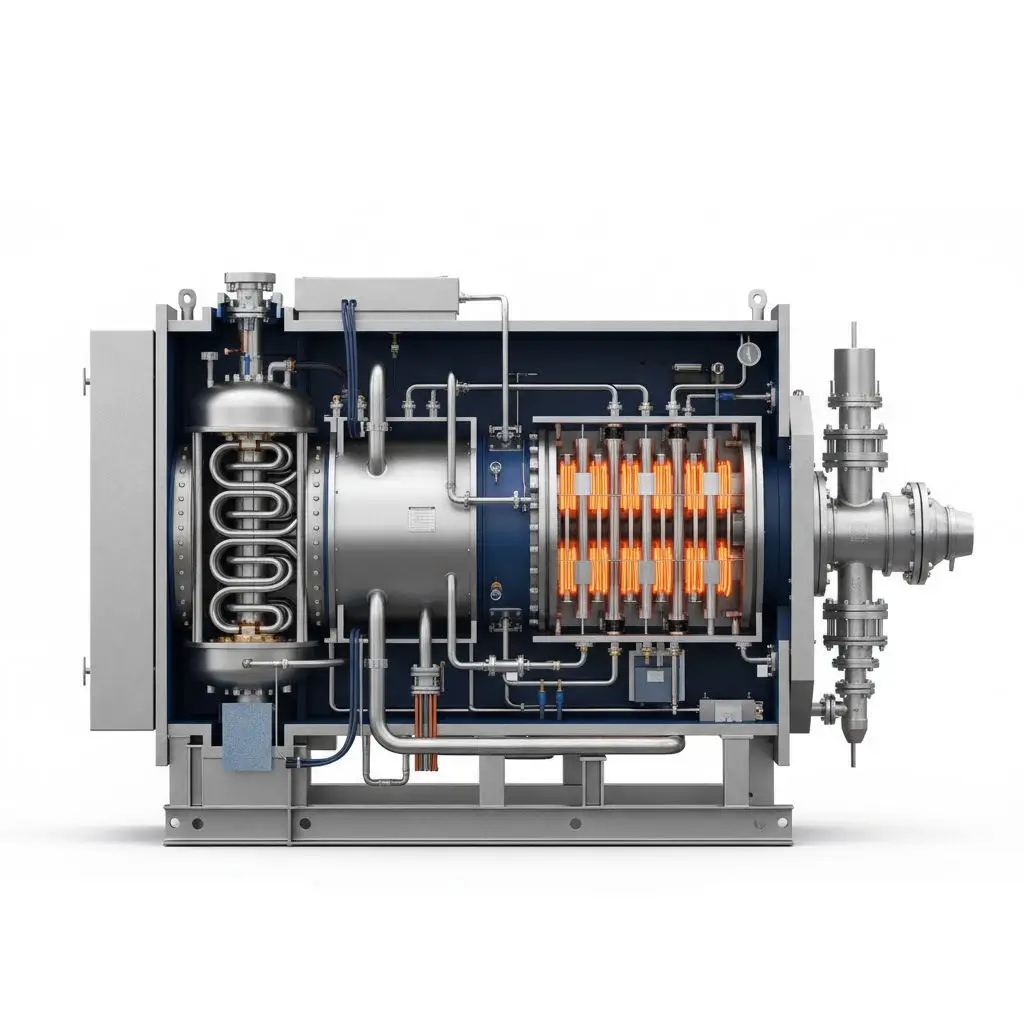

Oil and gas operations use electric heating on process streams, reboilers, fuel gas, tanks and pipelines where accurate temperature control, fast response and integration with hazardous area designs are critical. Electric systems can be easier to control than combustion-based heaters and can support wider decarbonisation plans. Intelligent SCR power control helps to manage large connected loads, improve stability and provide useful diagnostics to DCS and SCADA systems.