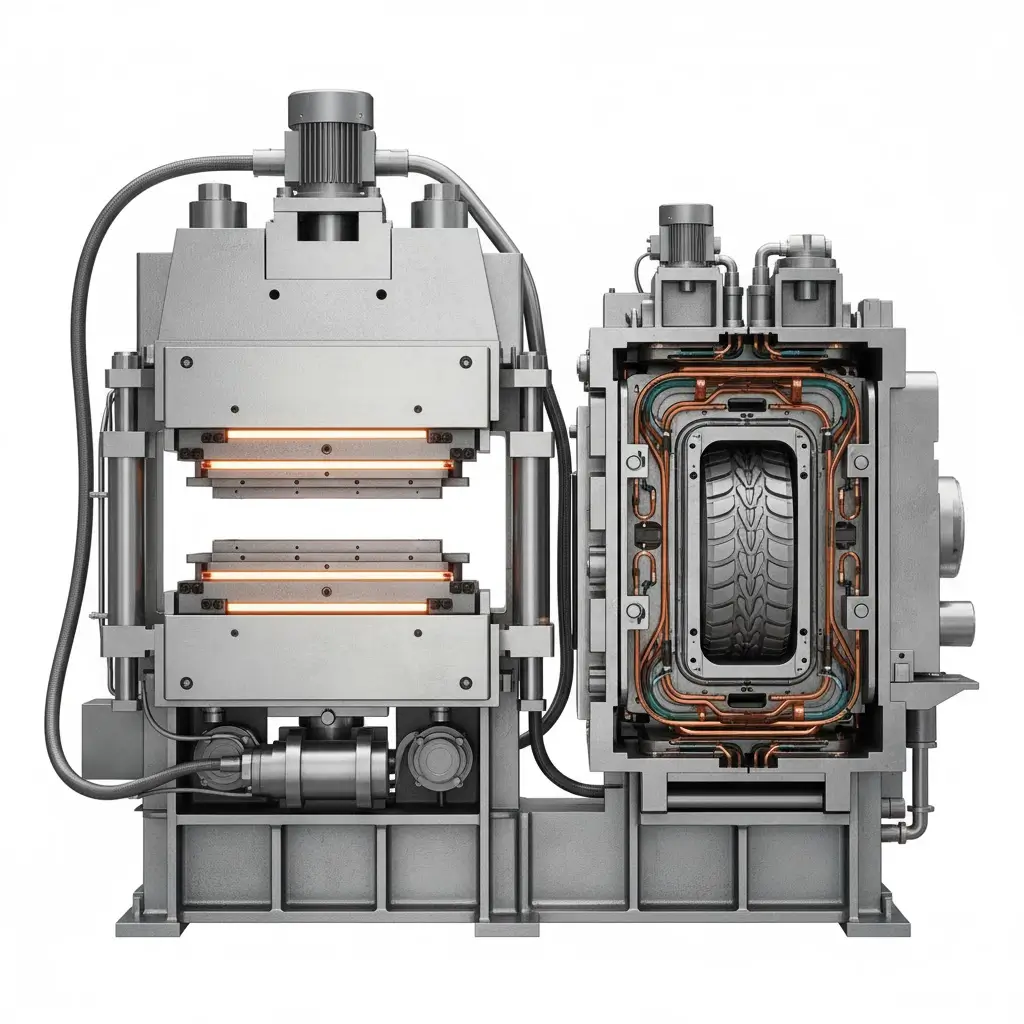

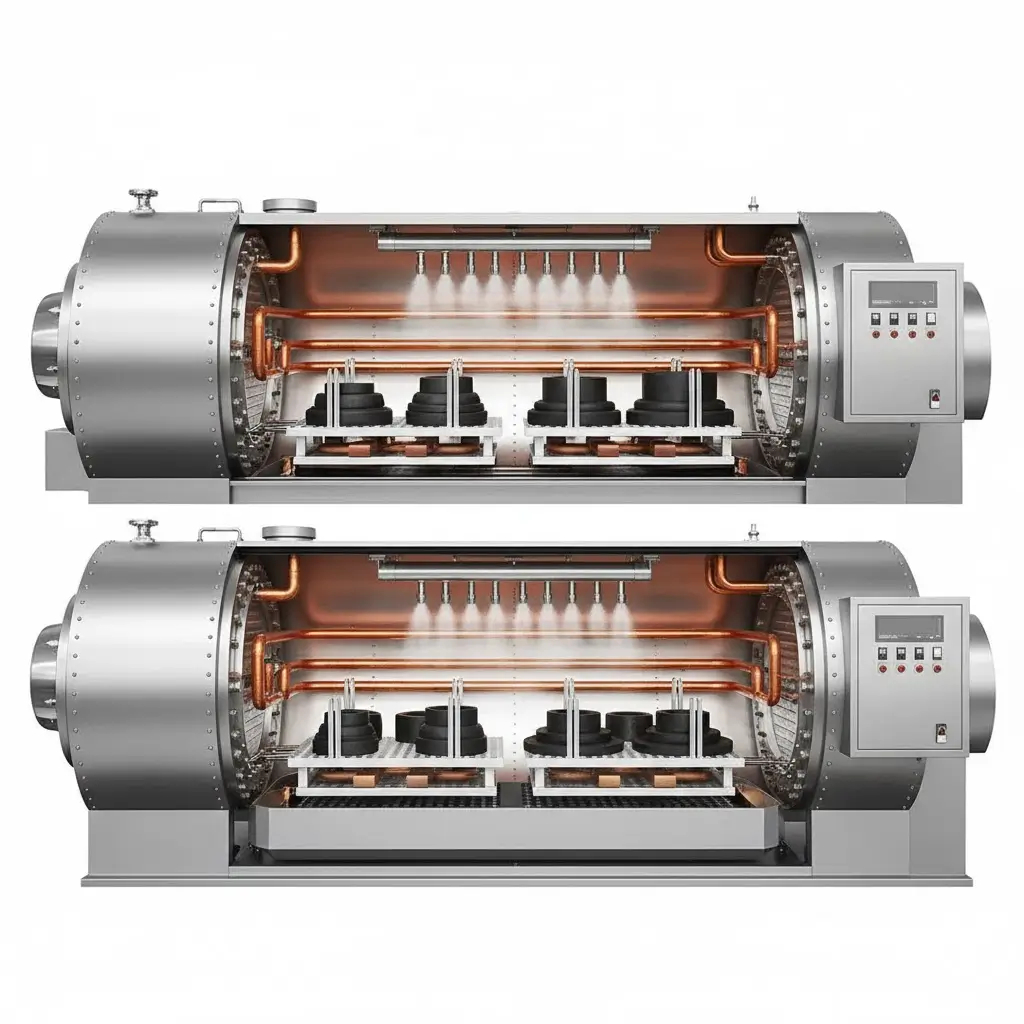

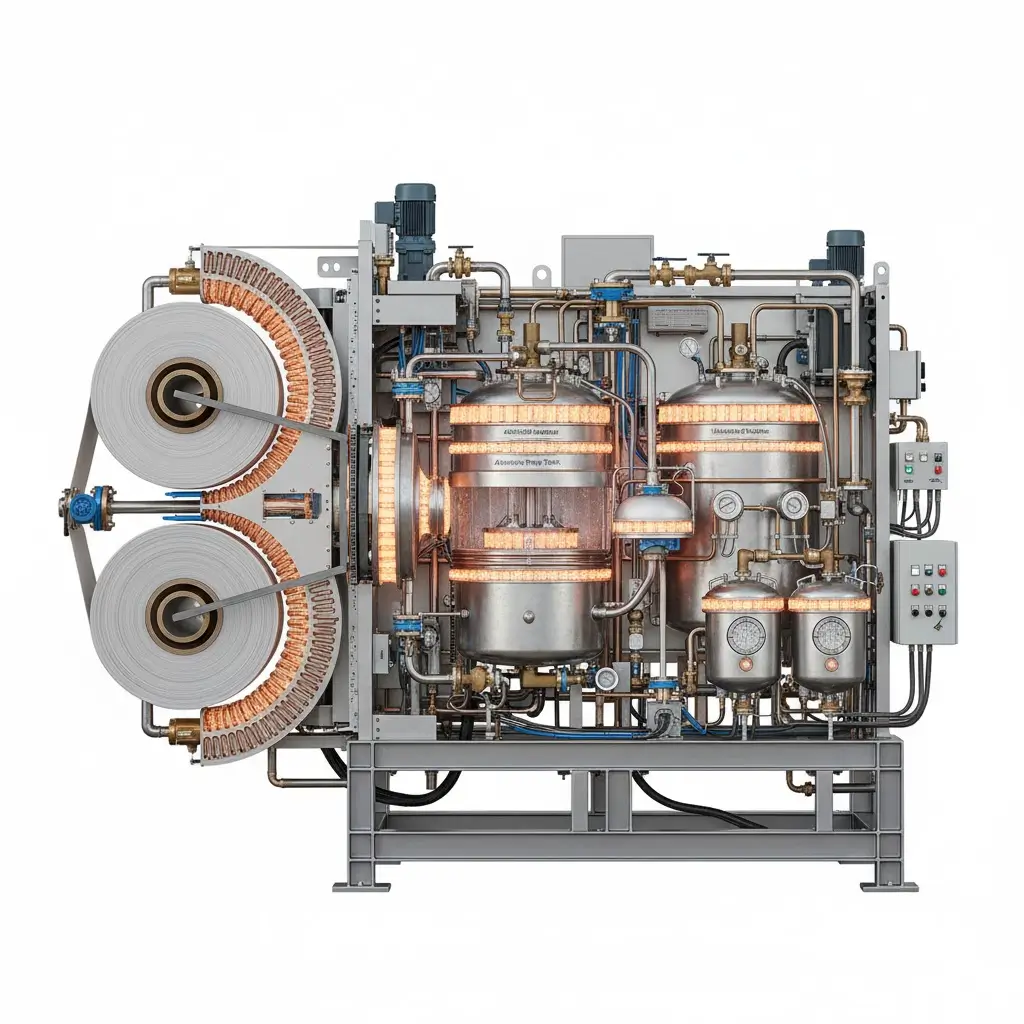

CD Automation provides SCR/thyristor power control for rubber and elastomer processing, from Banbury mixer preheaters and extrusion lines to curing presses, autoclaves, continuous vulcanisation lines and post-cure ovens. REVO controllers help stabilise temperature profiles, support consistent cure and provide useful data for maintenance and energy management.

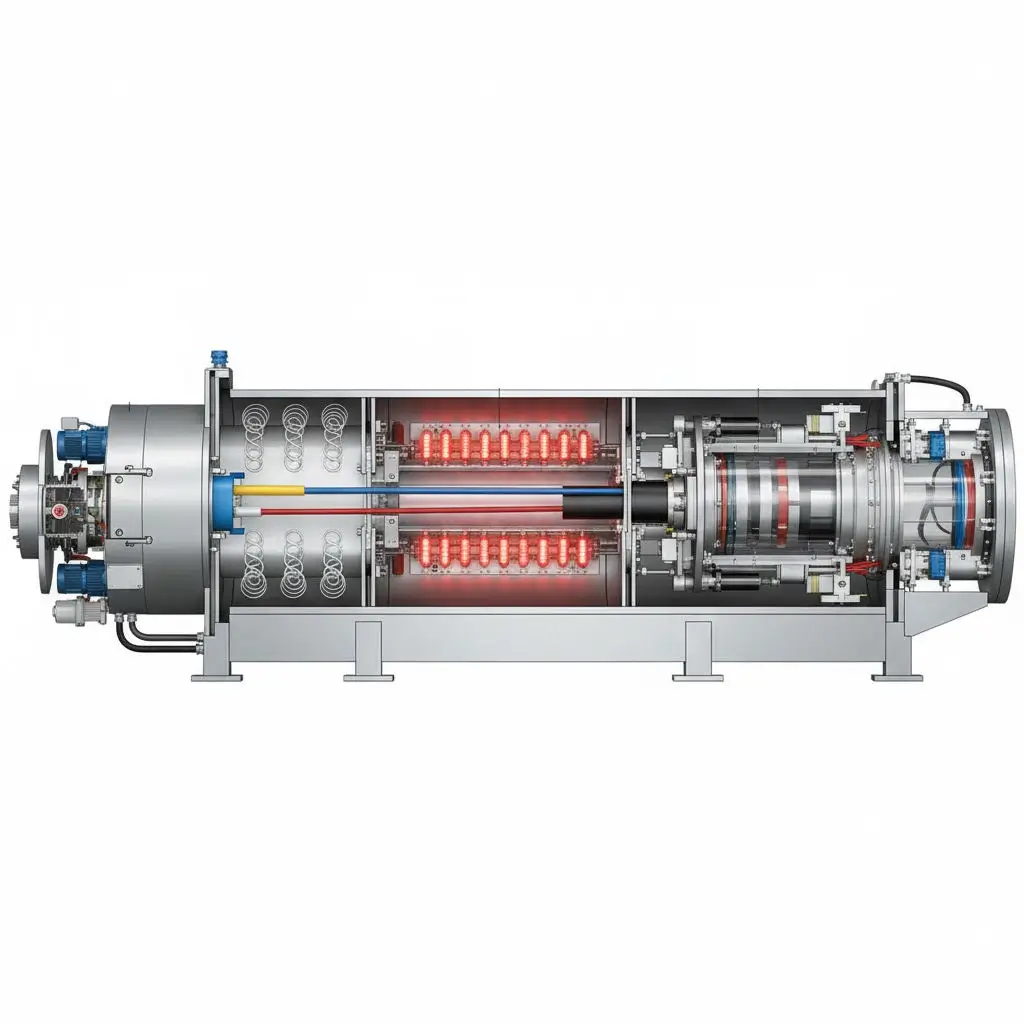

With REVO C for single zones, REVO-PN for compact multi-zone equipment and REVO-PC, or REVO-DPU zone control for larger lines and high-power systems, we integrate with OEM machinery, retrofits and plant PLC/SCADA platforms used by rubber processors and compounders.

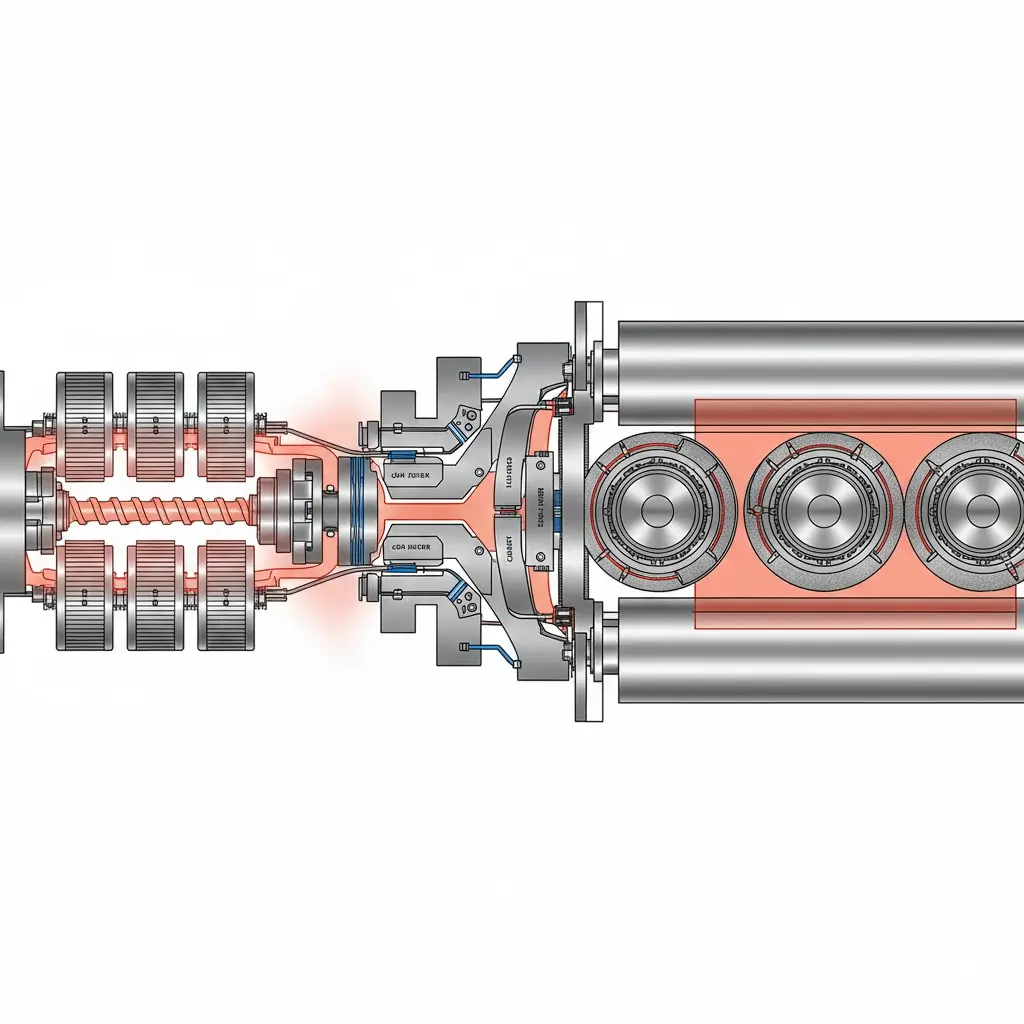

Rubber and elastomer manufacturing uses electric heating throughout compounding, forming and curing stages.

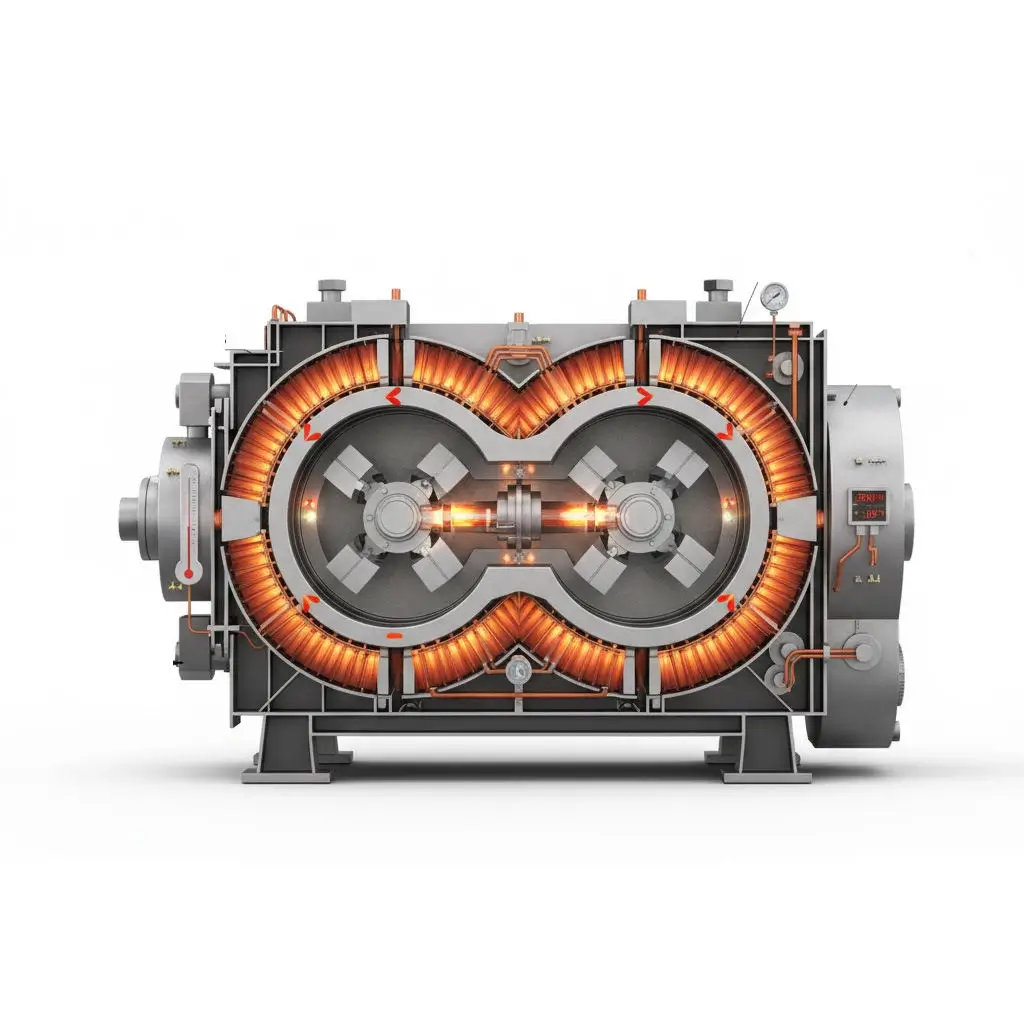

Mixers, extruders, calendars, presses, autoclaves, continuous vulcanisation lines and post-cure ovens all rely on stable, repeatable thermal conditions to achieve target cure and mechanical properties. Intelligent SCR power control can improve temperature stability, help manage electrical demand and provide data that supports quality, maintenance and energy projects.