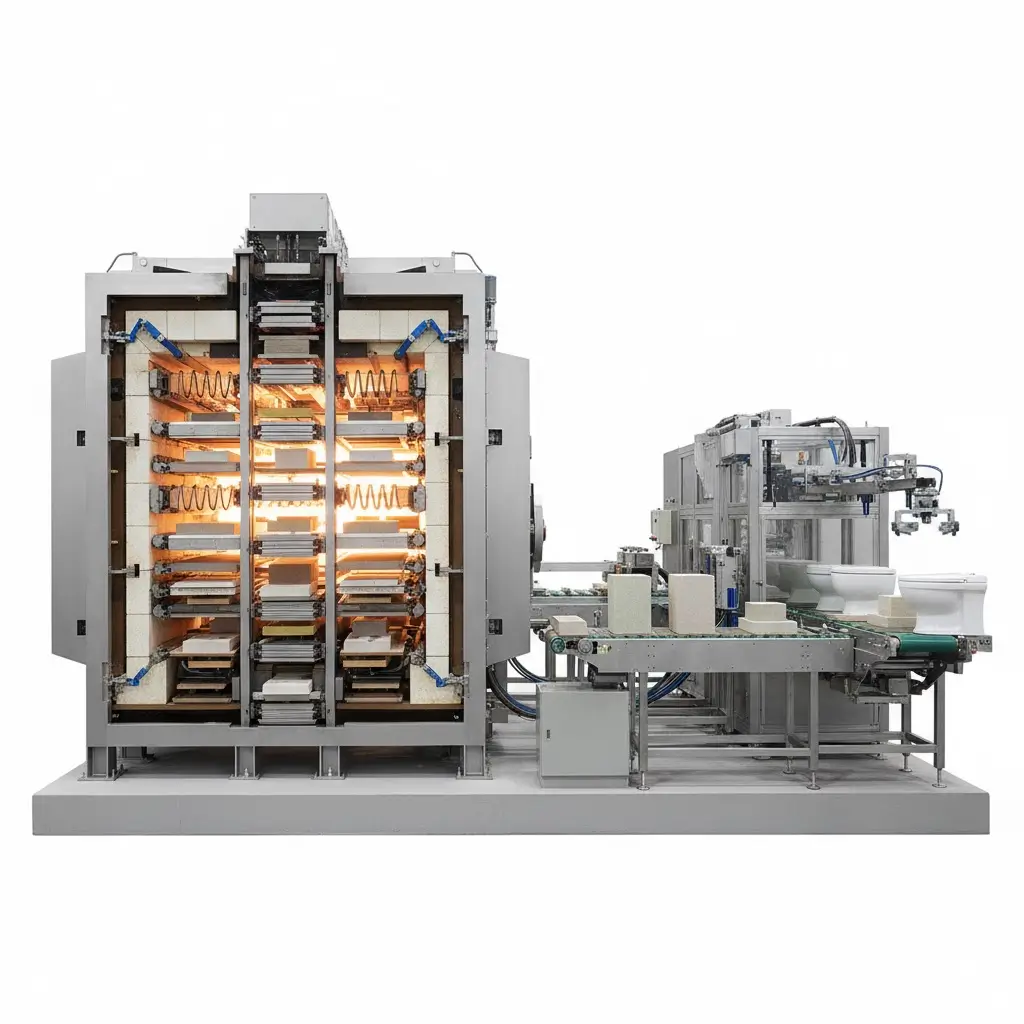

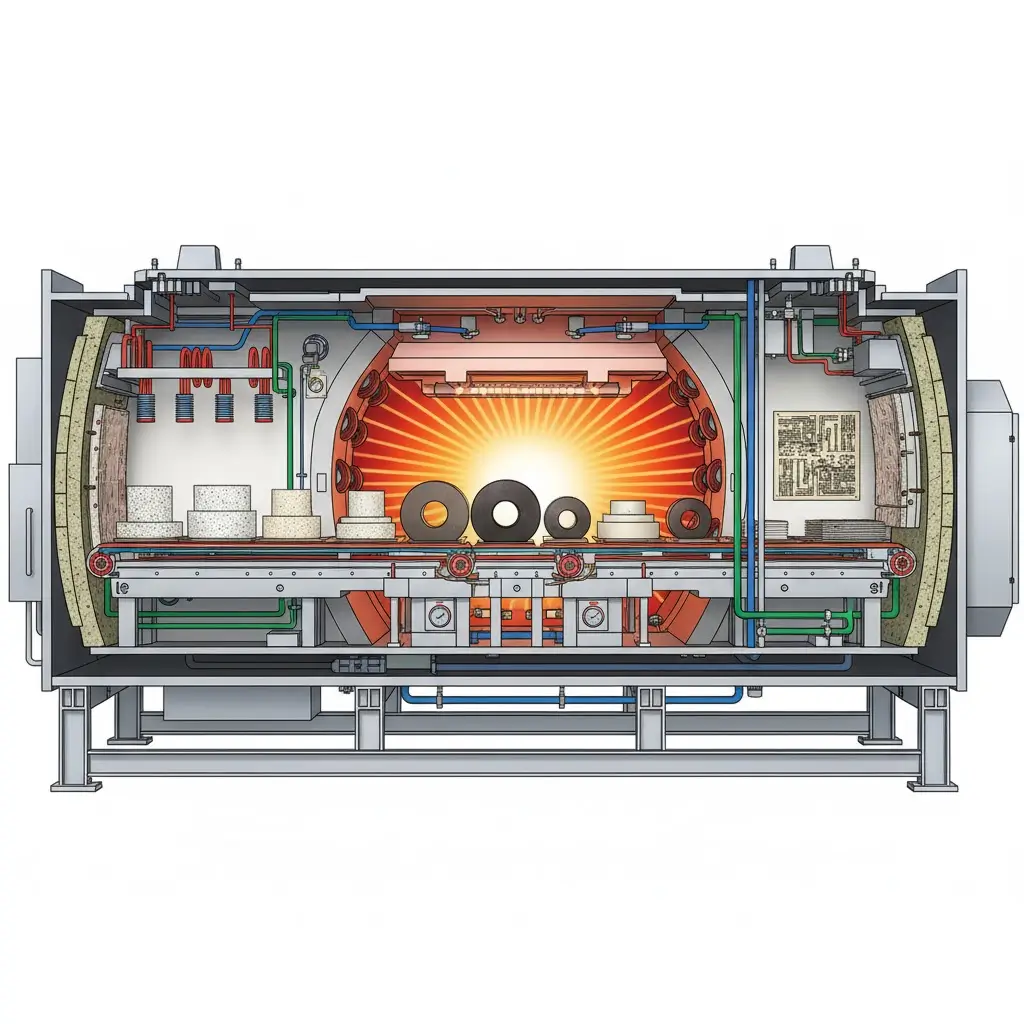

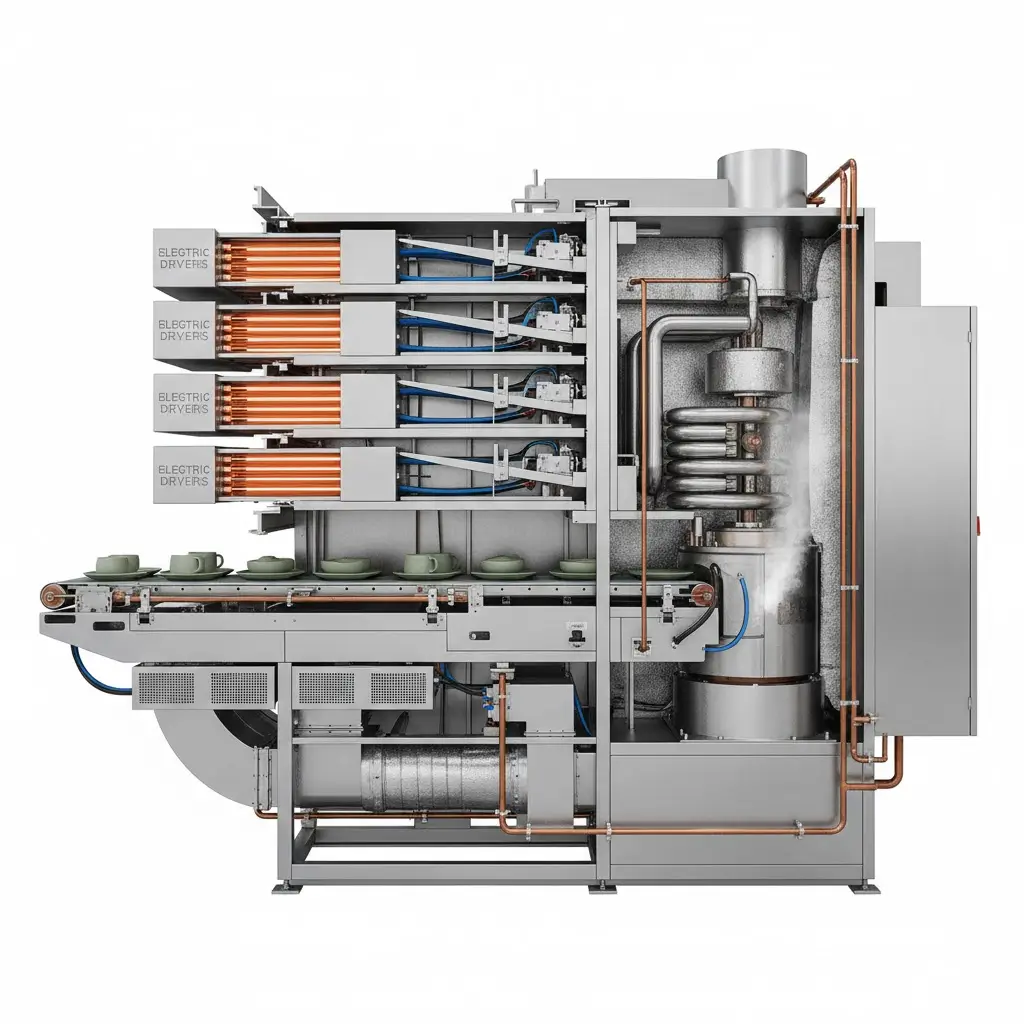

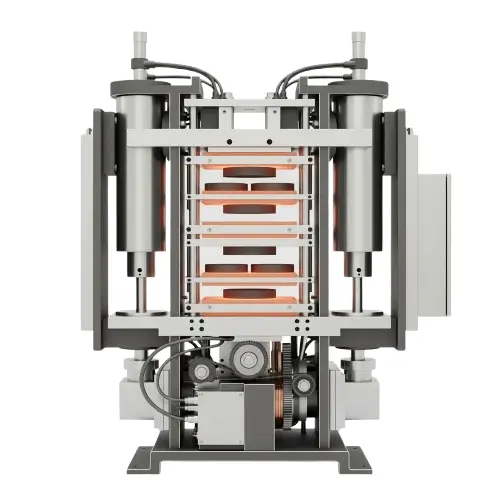

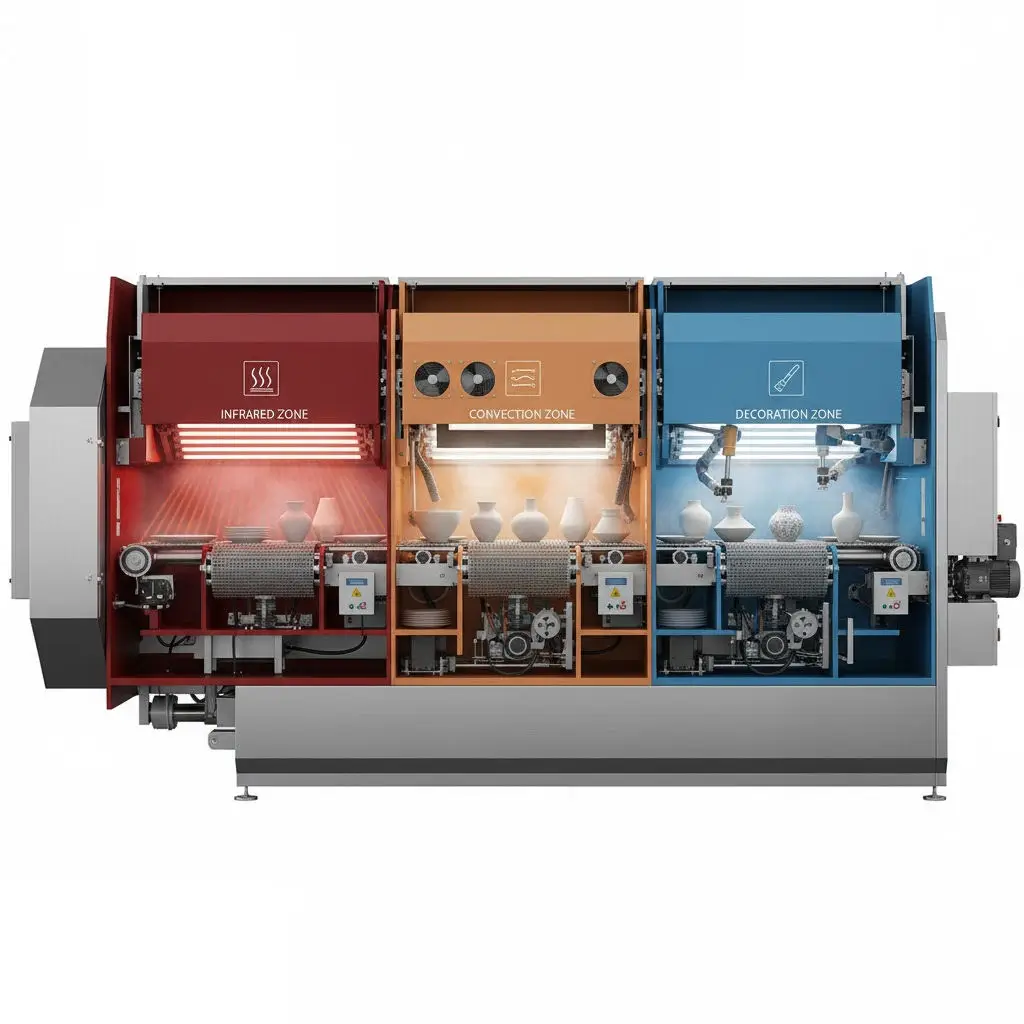

CD Automation provides SCR/thyristor power control for ceramics and technical ceramics - from batch and shuttle kilns and tunnel lines to high-temperature sintering furnaces, dryers and press tooling. REVO controllers help improve temperature uniformity, support complex firing profiles and provide useful data for quality and maintenance.

With REVO C for single zones, REVO-PN for compact multi-zone systems, and REVO-PC, or REVO-DPU zone control for larger kilns and furnaces, we integrate with PLC, furnace controllers and SCADA platforms used by OEMs, integrators and end-users.

Ceramics, technical ceramics and tiles rely on electric heating in kilns, furnaces, dryers and press tooling.

Precise, repeatable temperature control is essential to achieve the required microstructure, strength and dimensional stability. Intelligent SCR power control can improve temperature stability, help manage electrical demand and provide data that supports quality assurance and maintenance as plants modernise and expand their product range.