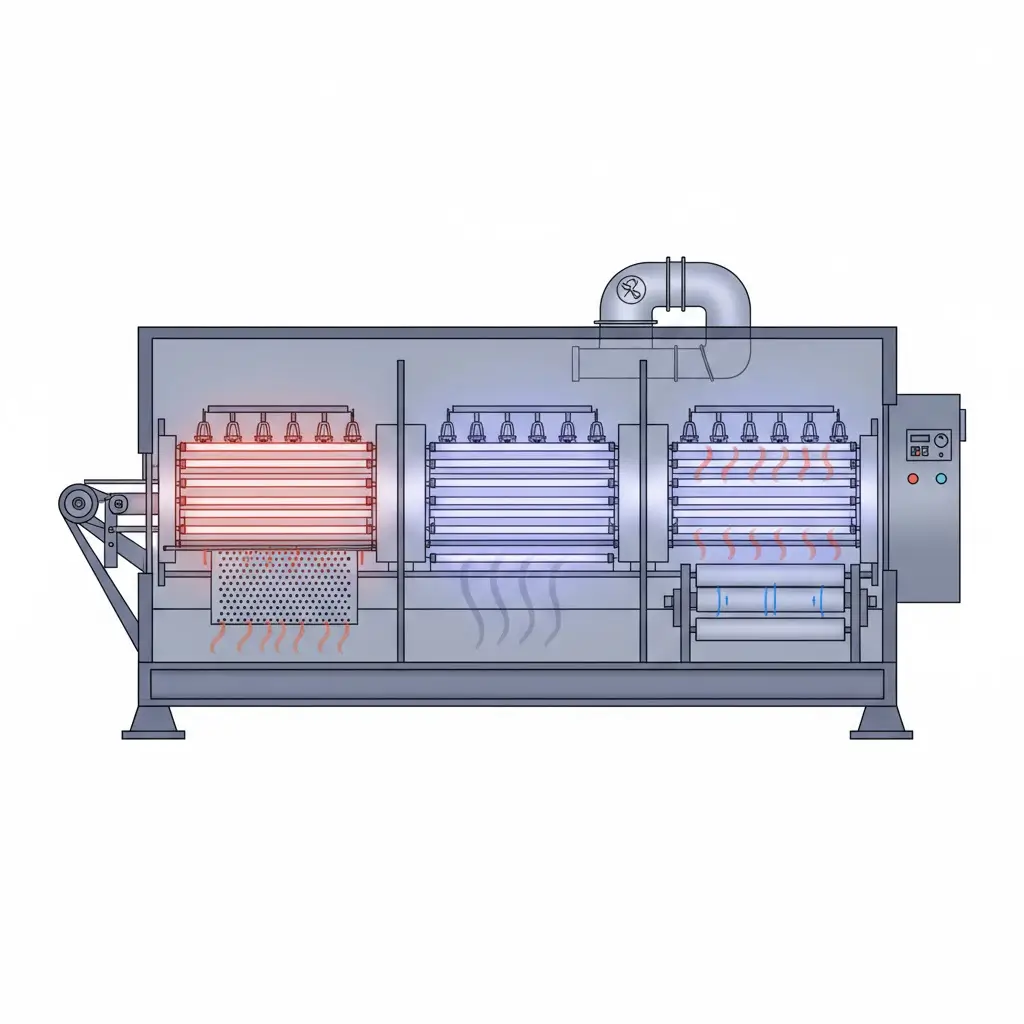

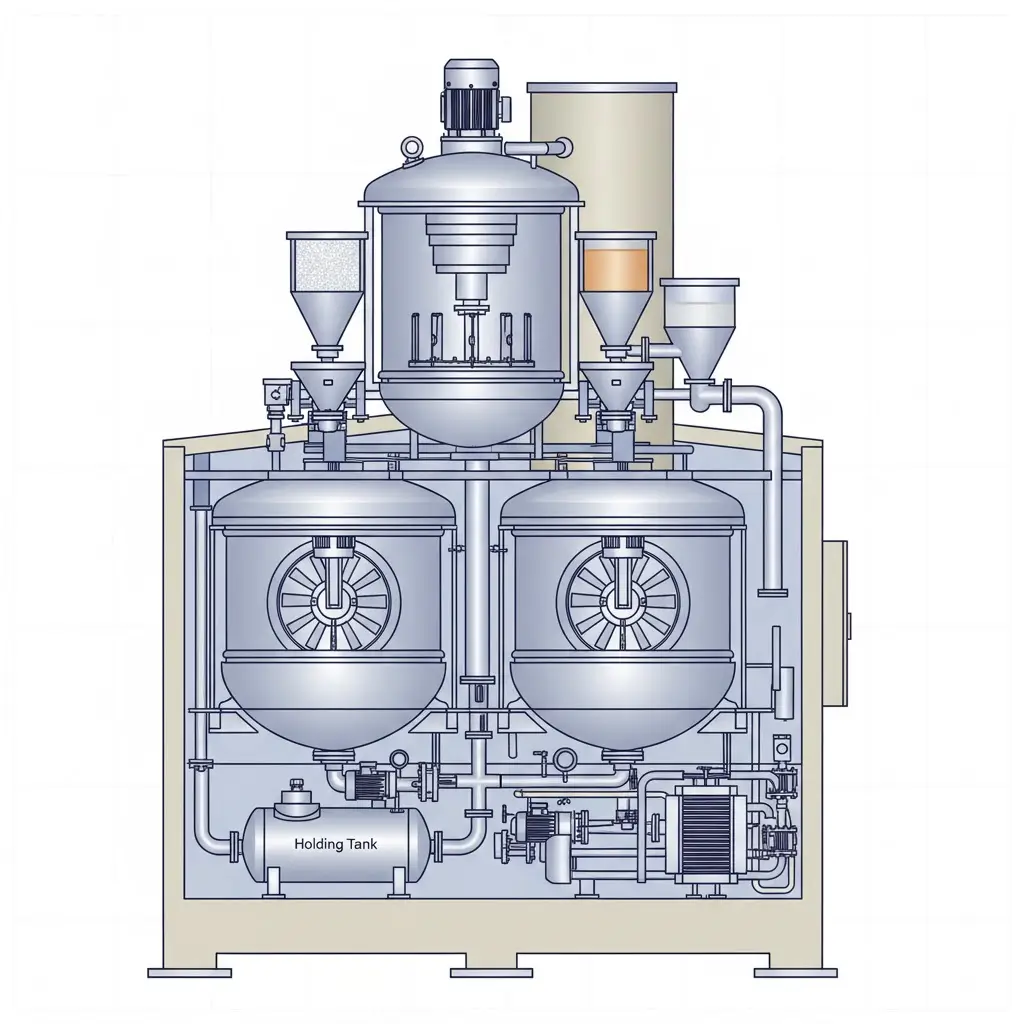

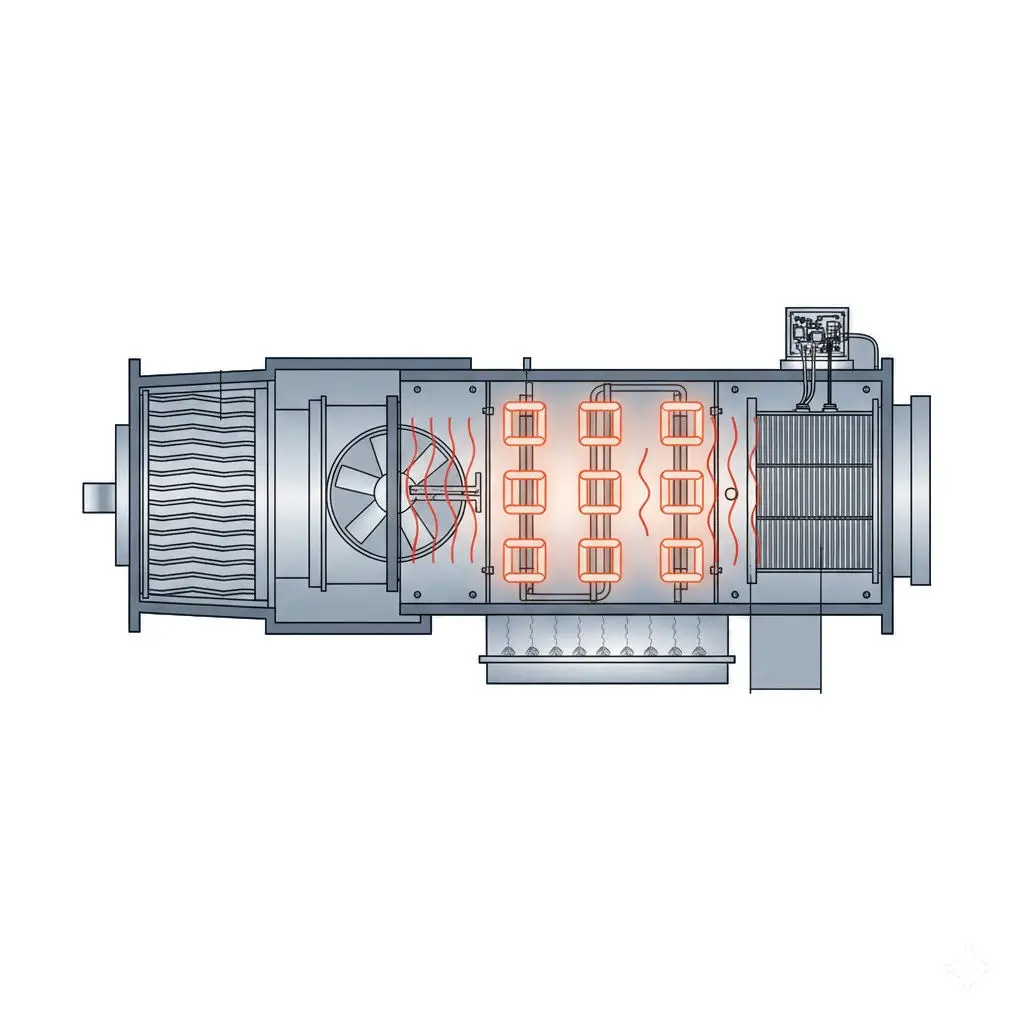

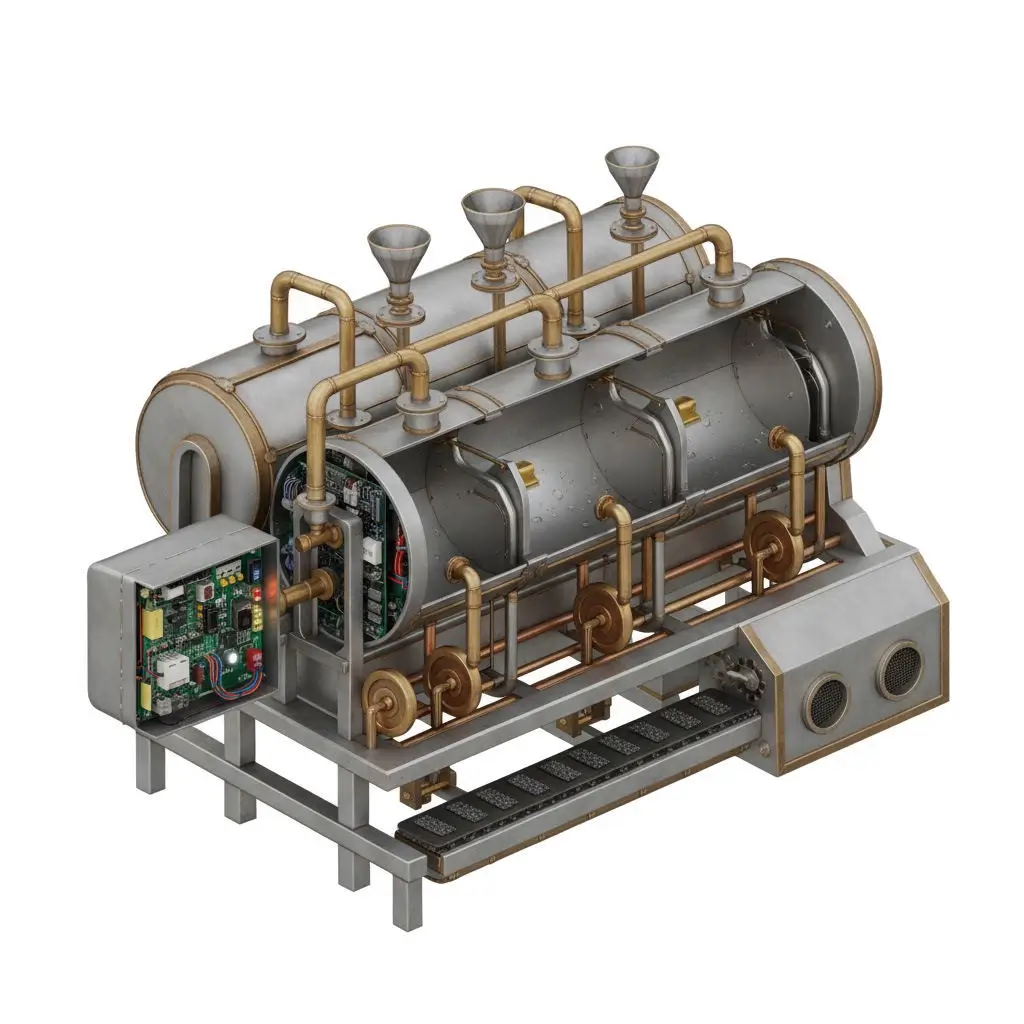

CD Automation provides SCR/thyristor power control for pulp, paper, board and print operations - from IR/web dryers and coating lines to adhesive reactors, laminators and make-up air systems. REVO controllers help stabilise drying conditions, reduce energy peaks and support consistent print and coating quality.

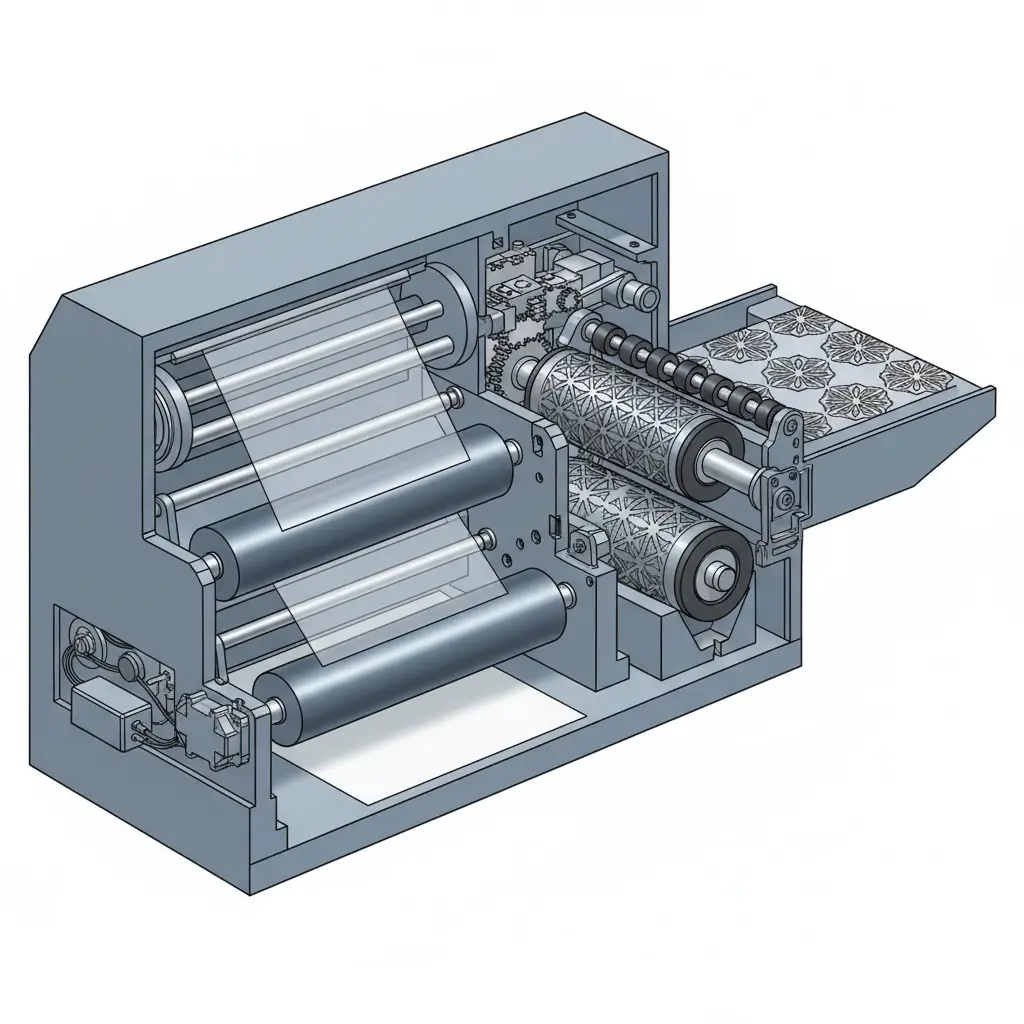

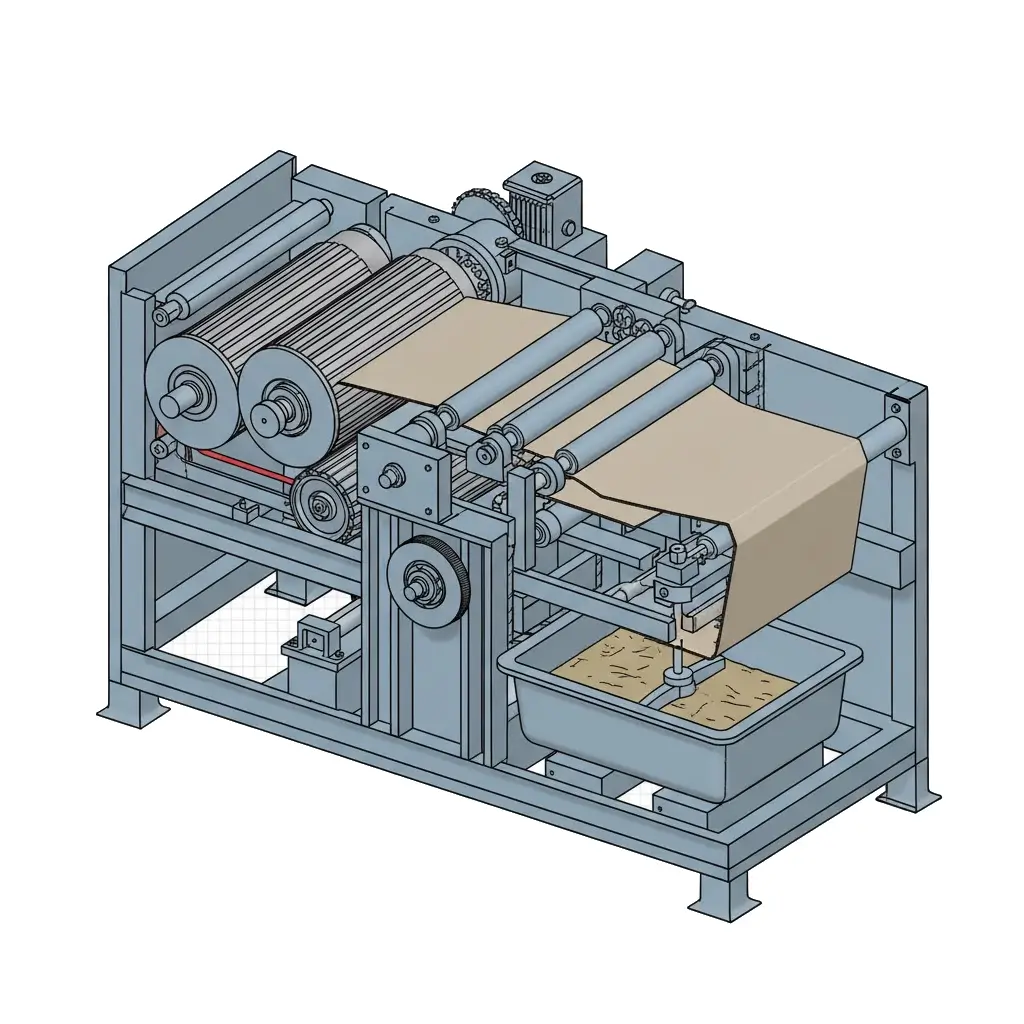

With REVO C for single zones, REVO-PN for compact multi-zone systems, and REVO-PC, or REVO-DPU zone control on larger lines, we integrate with existing mill and converter control systems and support both OEM and retrofit projects.

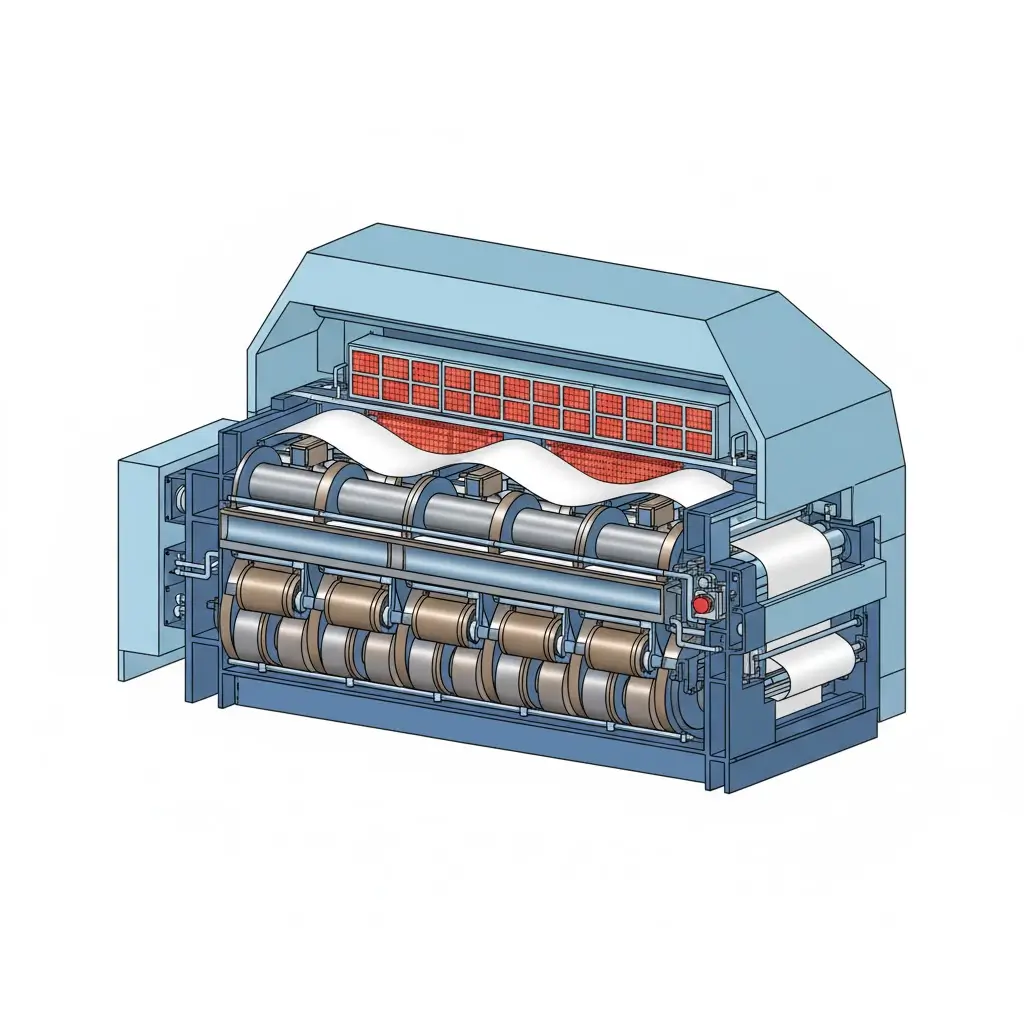

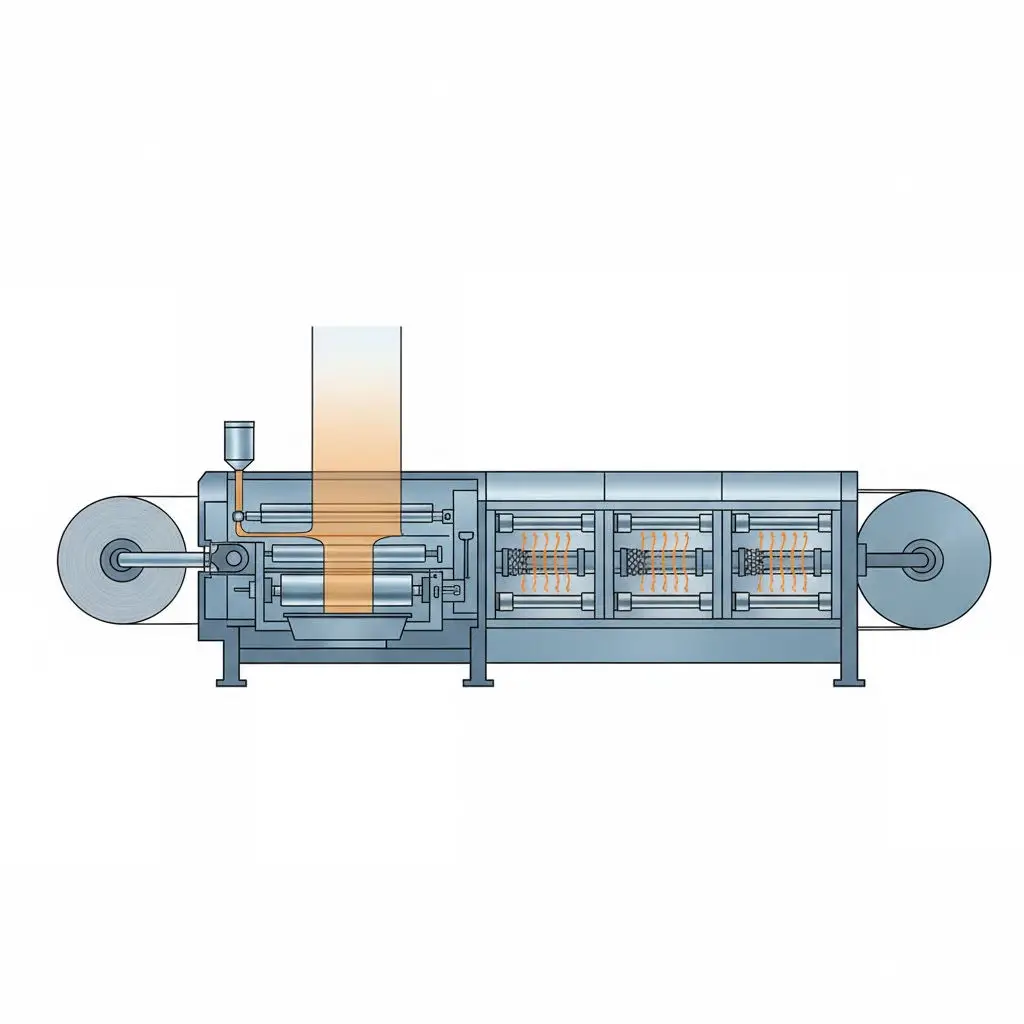

Pulp, paper, board and printing operations use electric heating in IR/web dryers, coating lines, ink dryers, adhesive kitchens and supporting utilities. Drying and curing conditions have a direct impact on web quality, print performance and waste levels. Intelligent SCR power control can improve temperature and power stability, help manage energy use and support modernisation of existing lines and equipment.