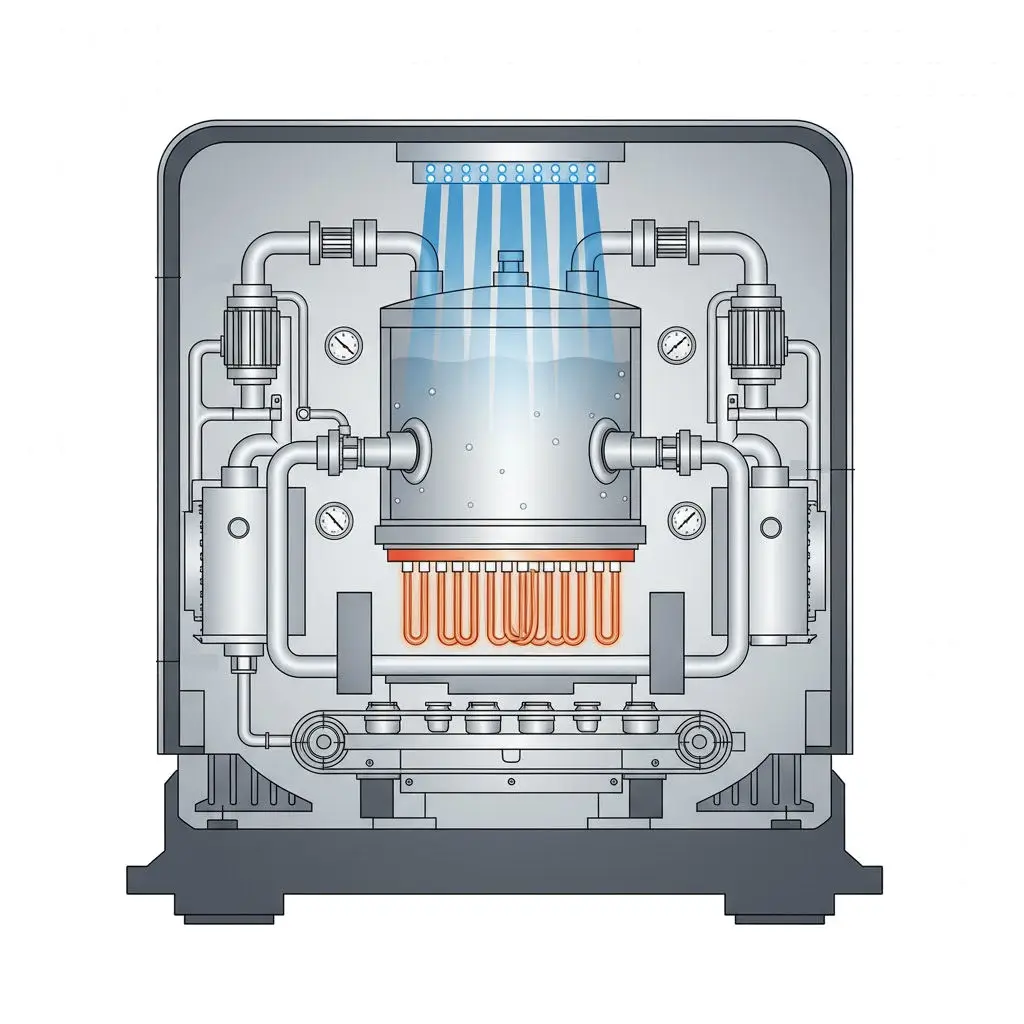

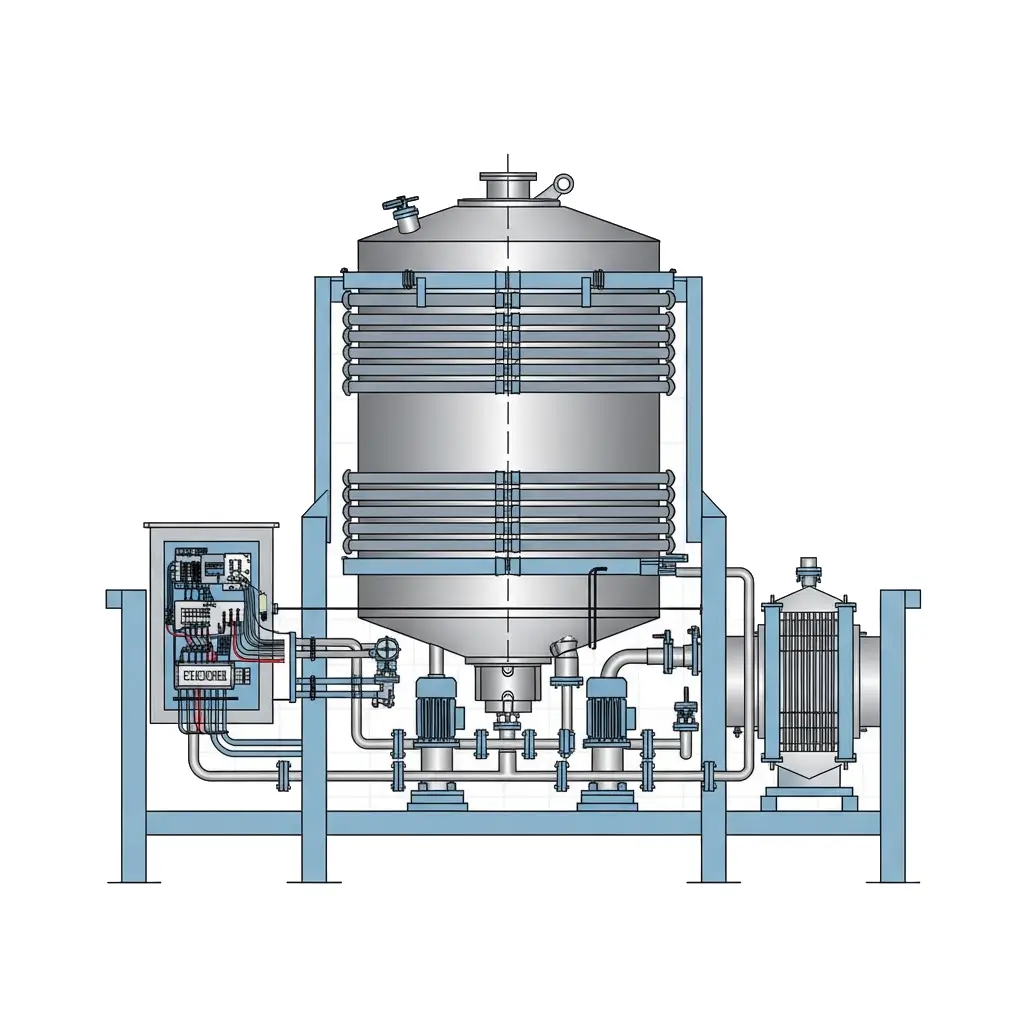

CD Automation supplies SCR/thyristor power control for chemical and polymer processes including jacketed reactors, distillation reboilers, dryers, tray ovens and tank farms. Our REVO controllers help improve temperature stability, support batch repeatability and provide useful diagnostic and energy data to automation systems.

With REVO C for single zones, REVO-PN for compact multi-zone systems, and REVO-PC, or REVO-DPU zone control for larger units and multi-reactor systems, we integrate with PLC, DCS and SCADA platforms using common fieldbuses.

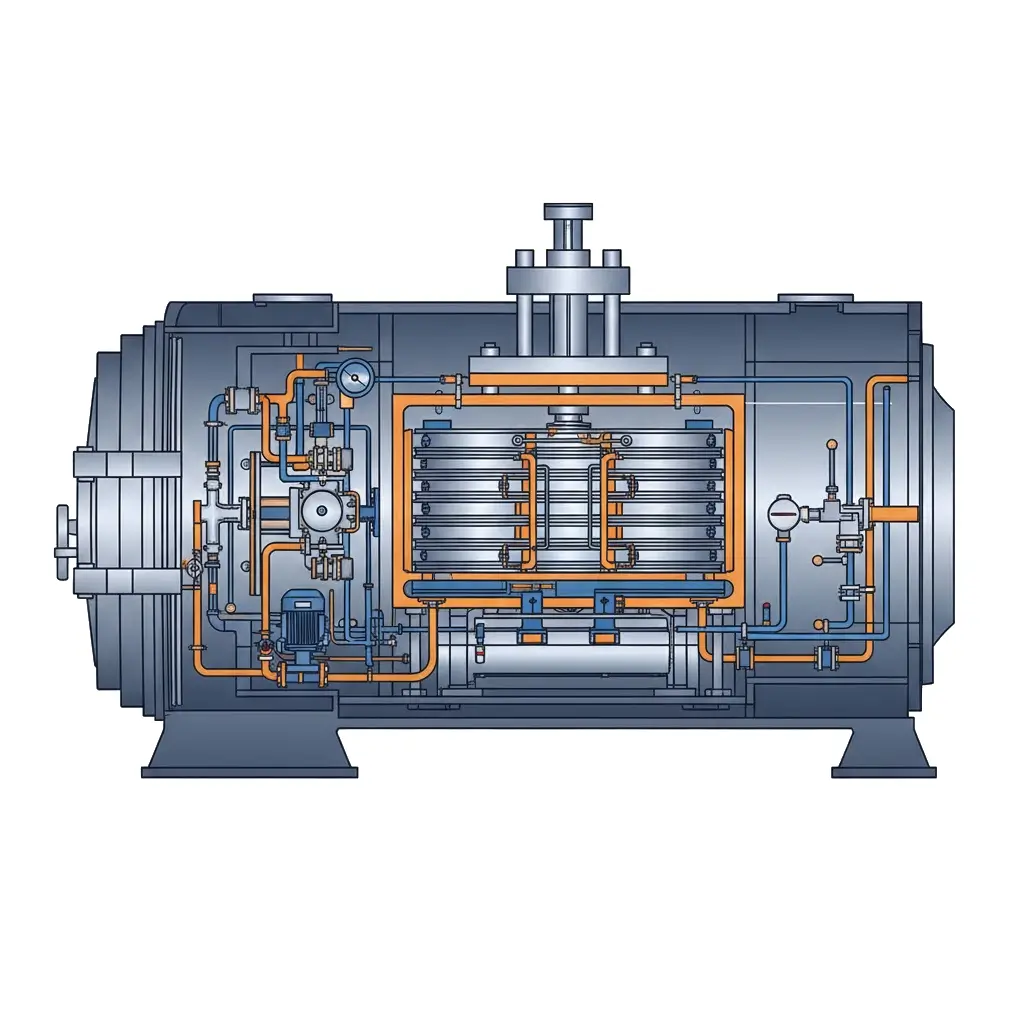

Chemical and polymer plants use electric heating on reactors, distillation systems, dryers and utilities where accurate temperature control, fast response and integration with automation systems are important.

Electric heaters can offer precise power delivery and flexible control compared with simple on/off systems.

Intelligent SCR power control from CD Automation supports temperature stability, batch repeatability and energy monitoring as sites modernise and optimise their processes.