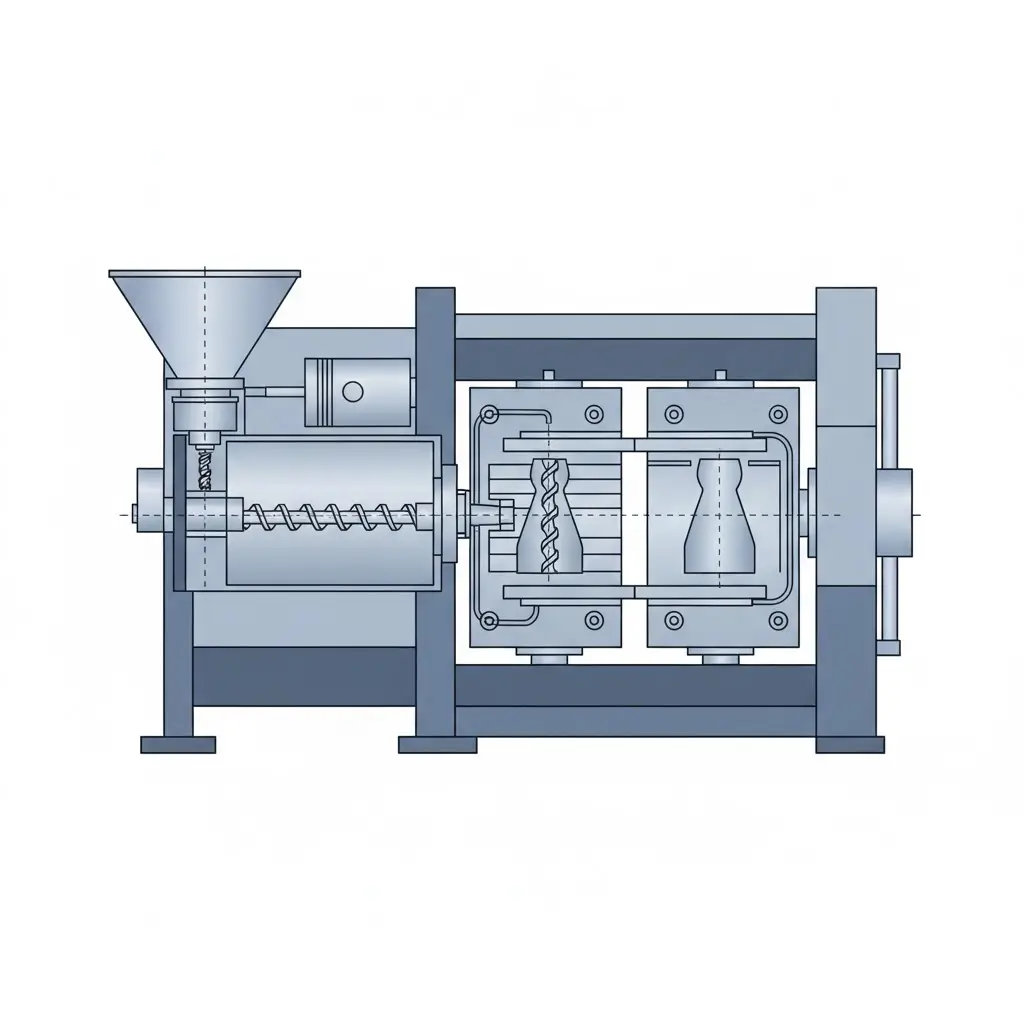

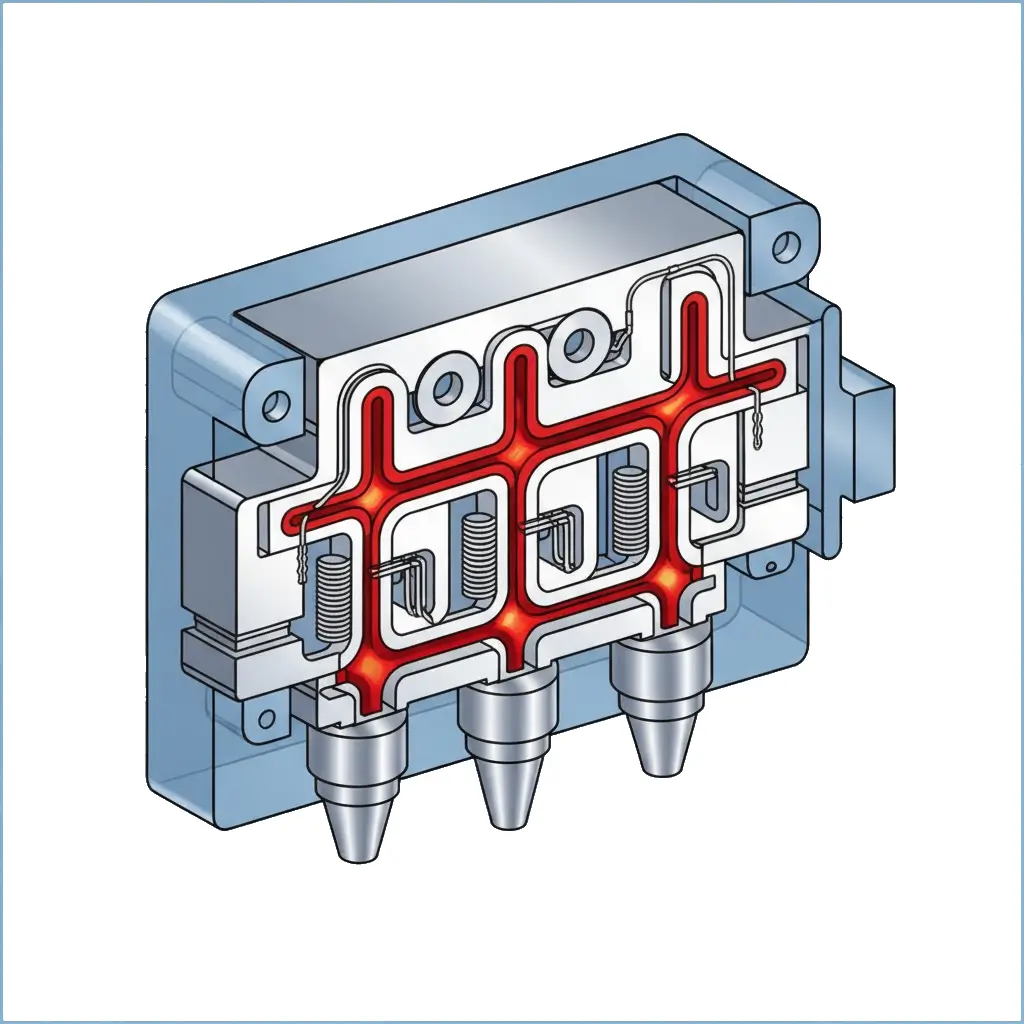

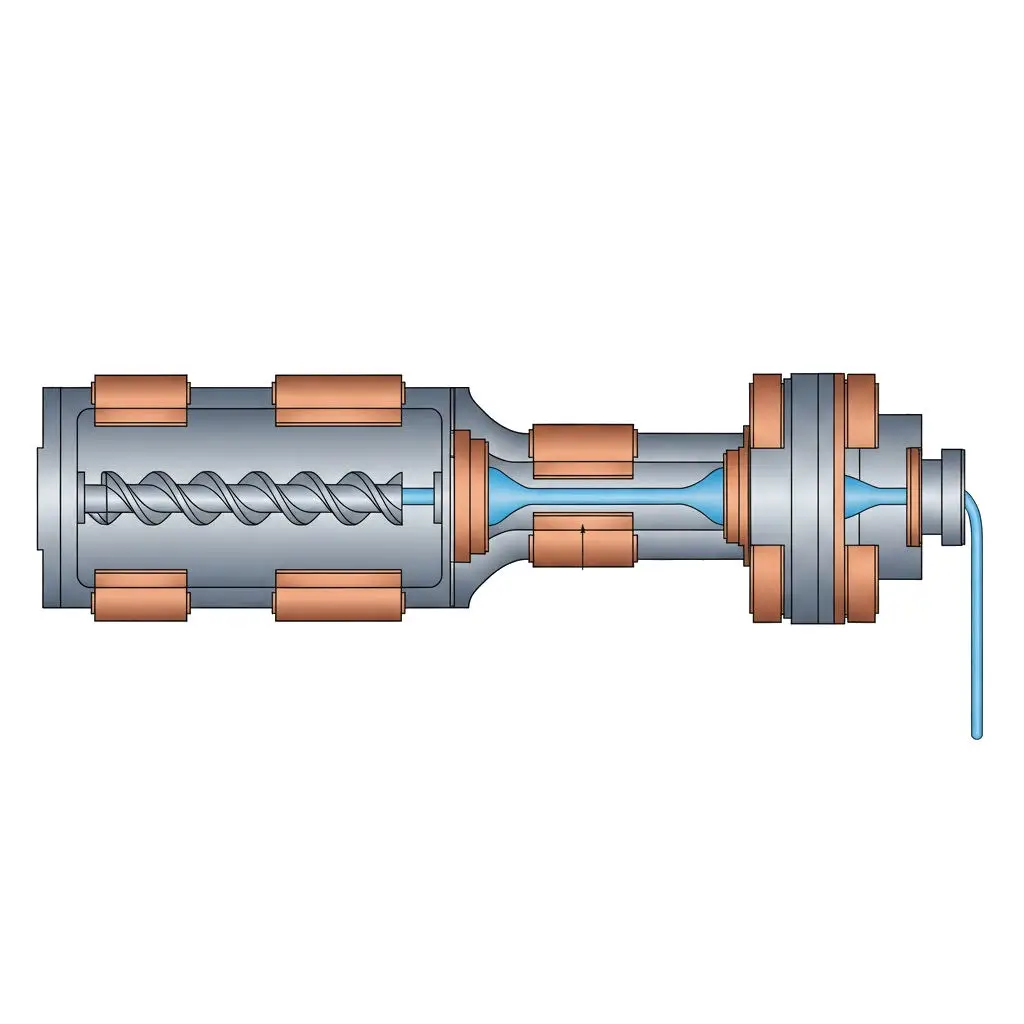

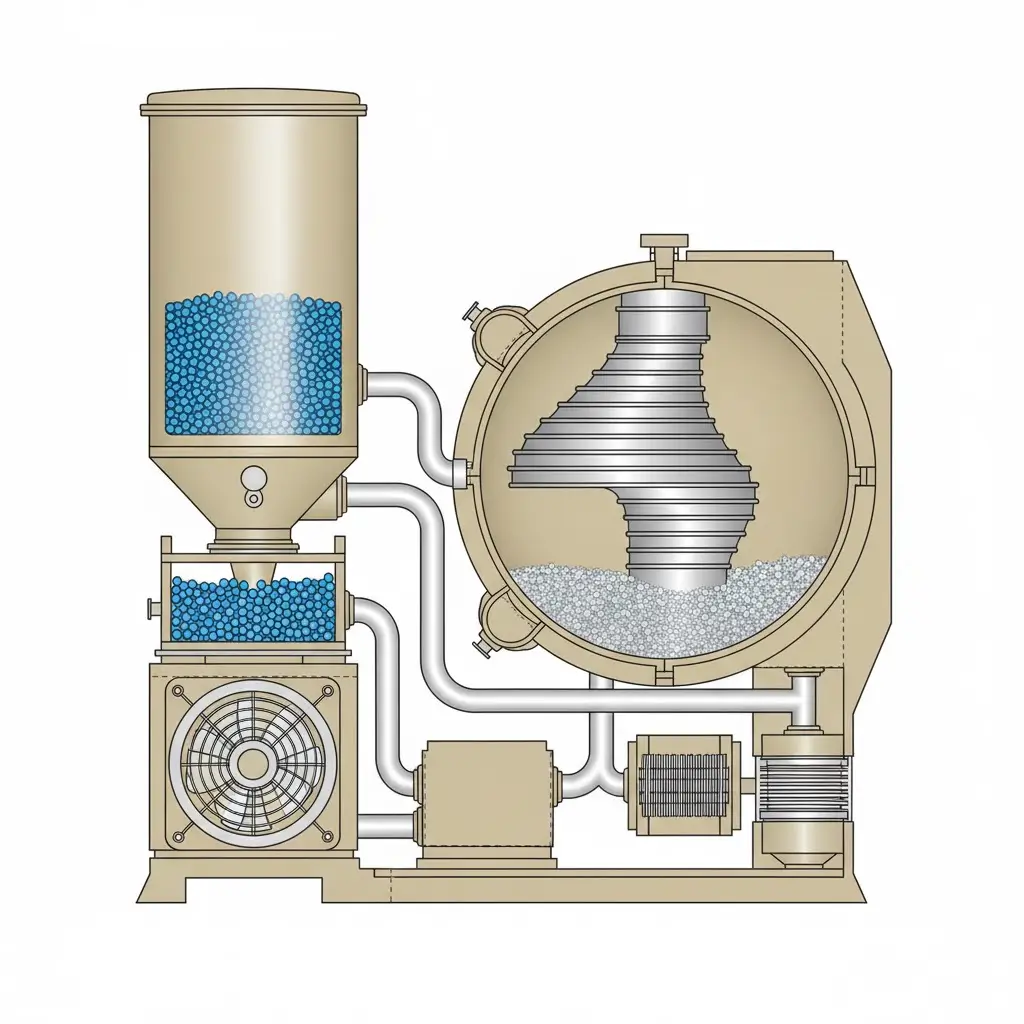

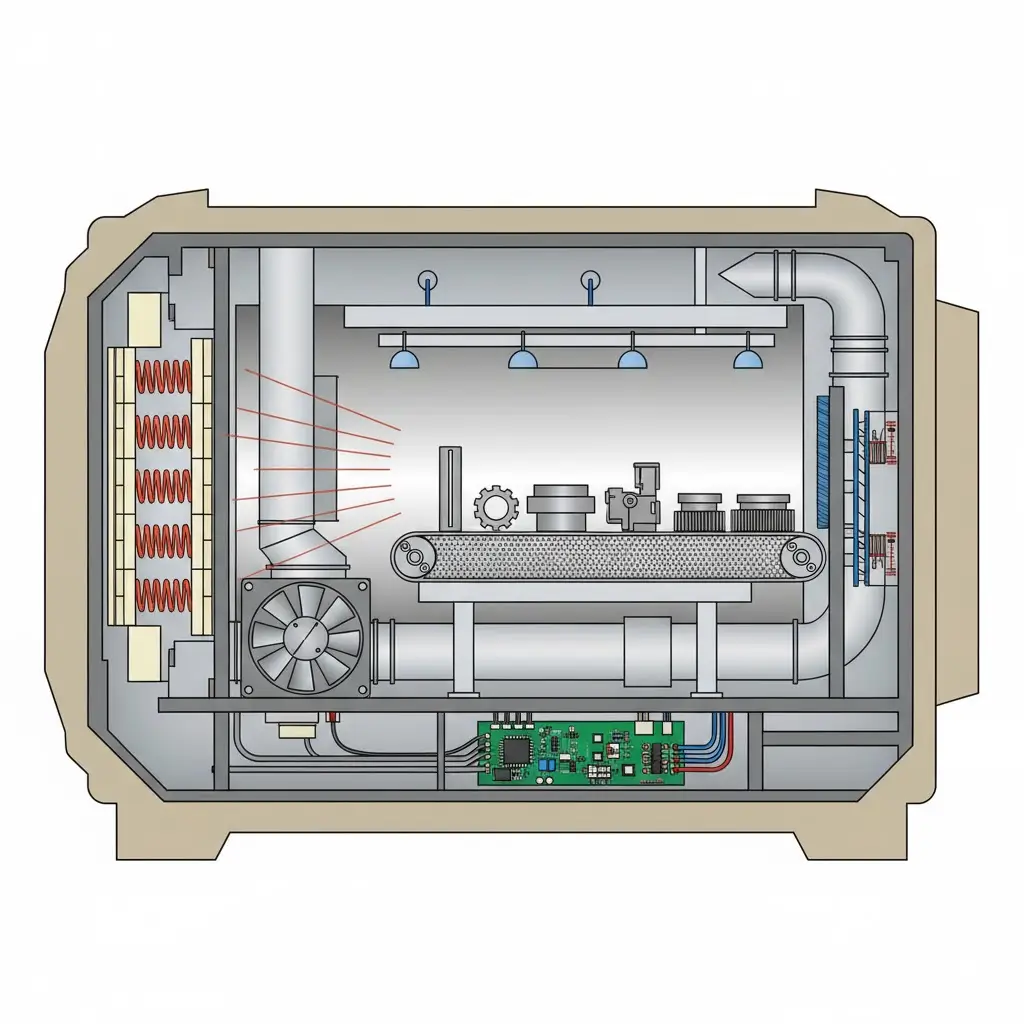

CD Automation provides SCR/thyristor power control for core plastics processing equipment, from injection moulding barrels and hot runners to extruder dies, thermoforming ovens and dryers. REVO controllers help improve temperature stability, reduce energy peaks and support consistent part quality across shifts.

With REVO C for single zones, REVO-PN for compact multi-zone systems, and REVO-PC, or REVO-DPU zone control on larger lines, we integrate easily with existing machine controls and new OEM designs.

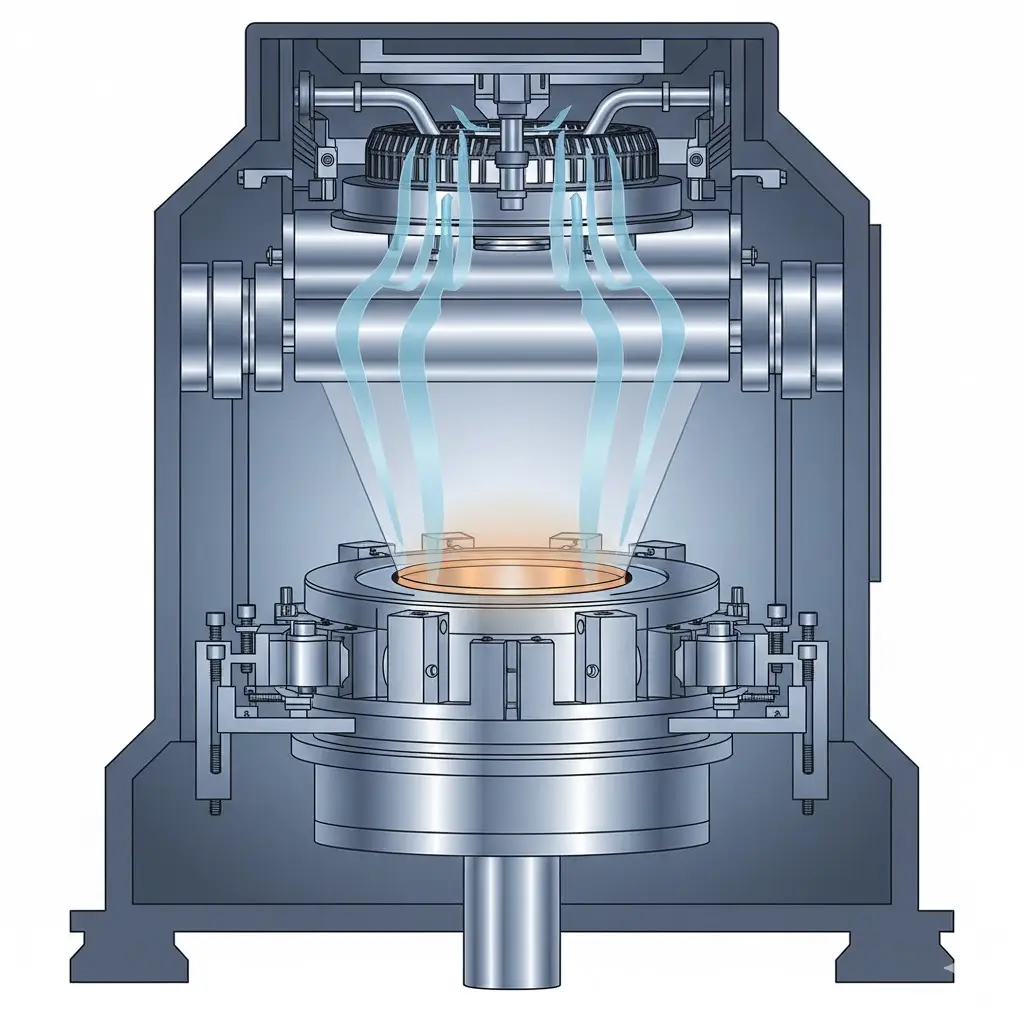

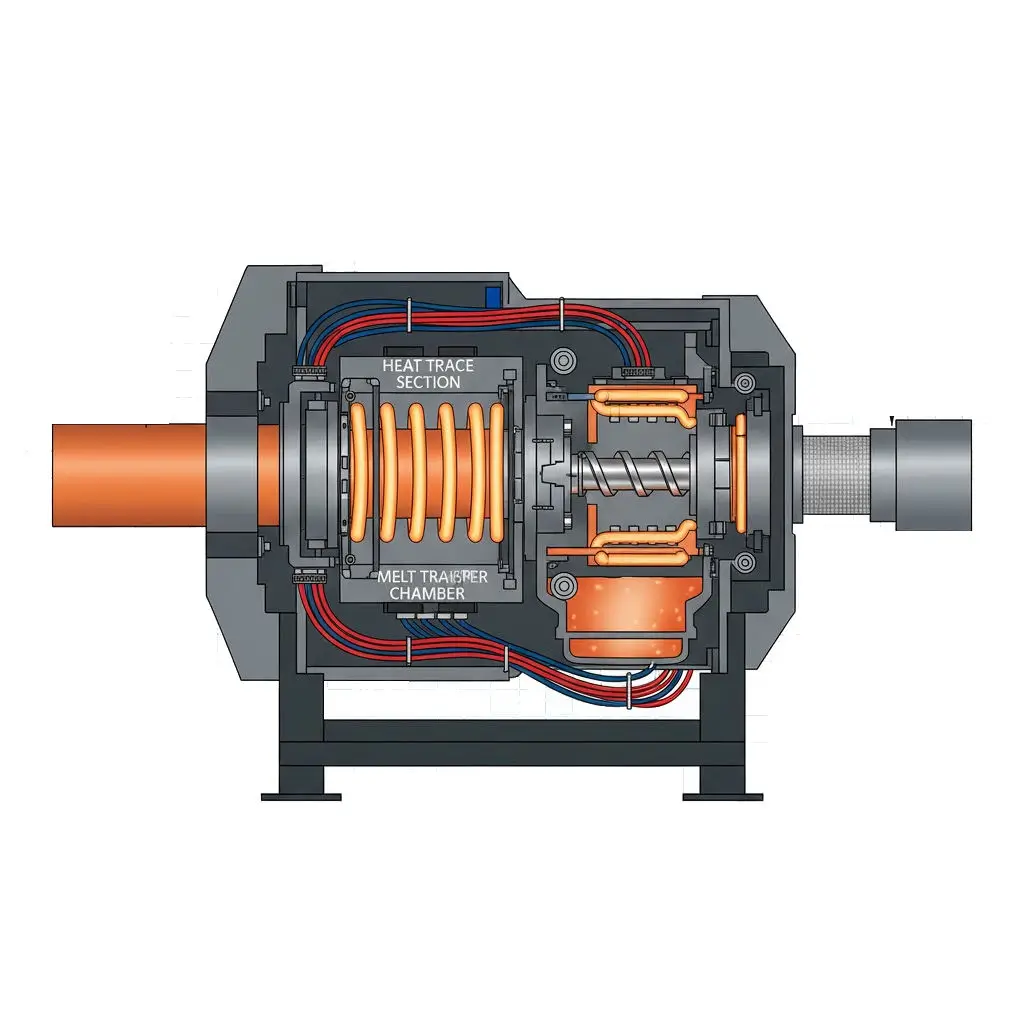

Plastics and polymer processing rely heavily on electric heating for barrels, nozzles, dies, film lines, ovens and resin dryers. Stable, repeatable temperature control is essential to maintain dimensional accuracy, surface finish and mechanical properties. Intelligent SCR power control can improve stability, reduce energy peaks and support modernisation of existing machines, helping processors increase efficiency and reduce scrap.