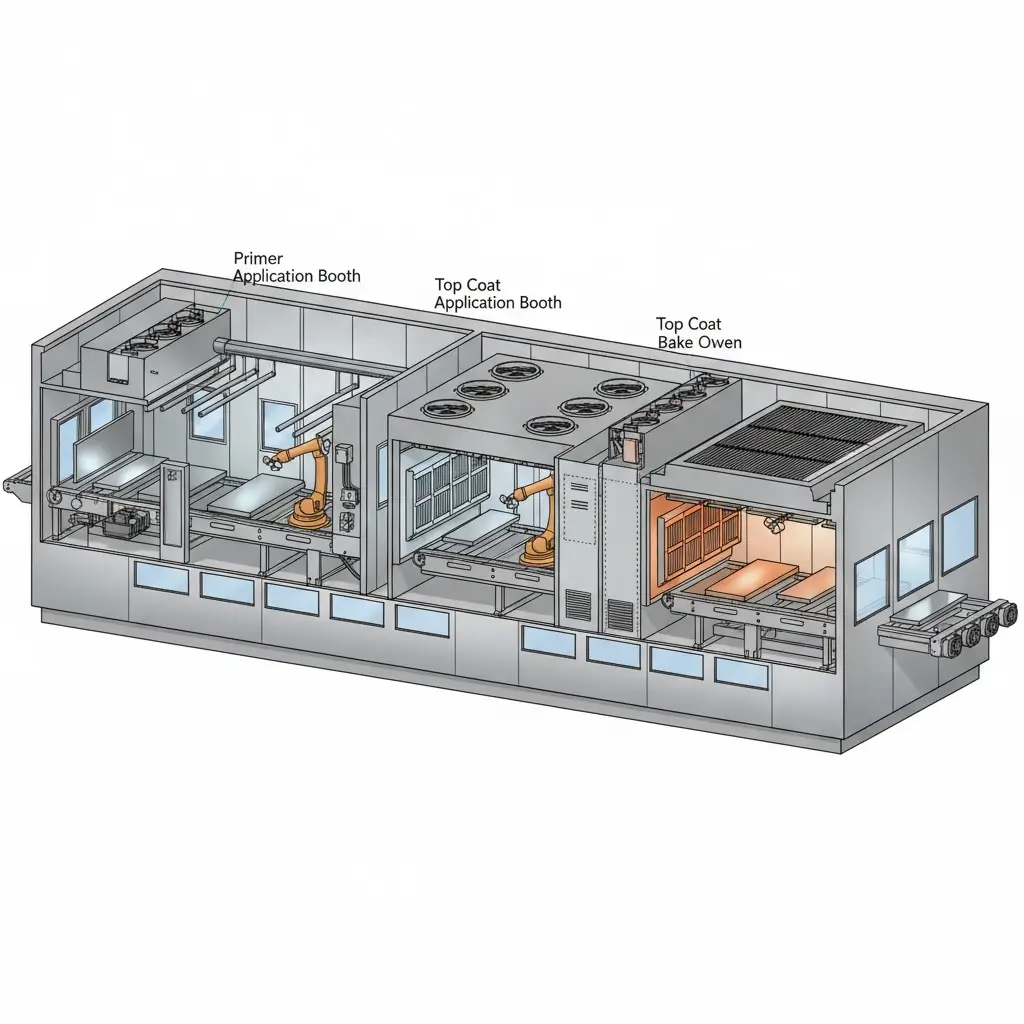

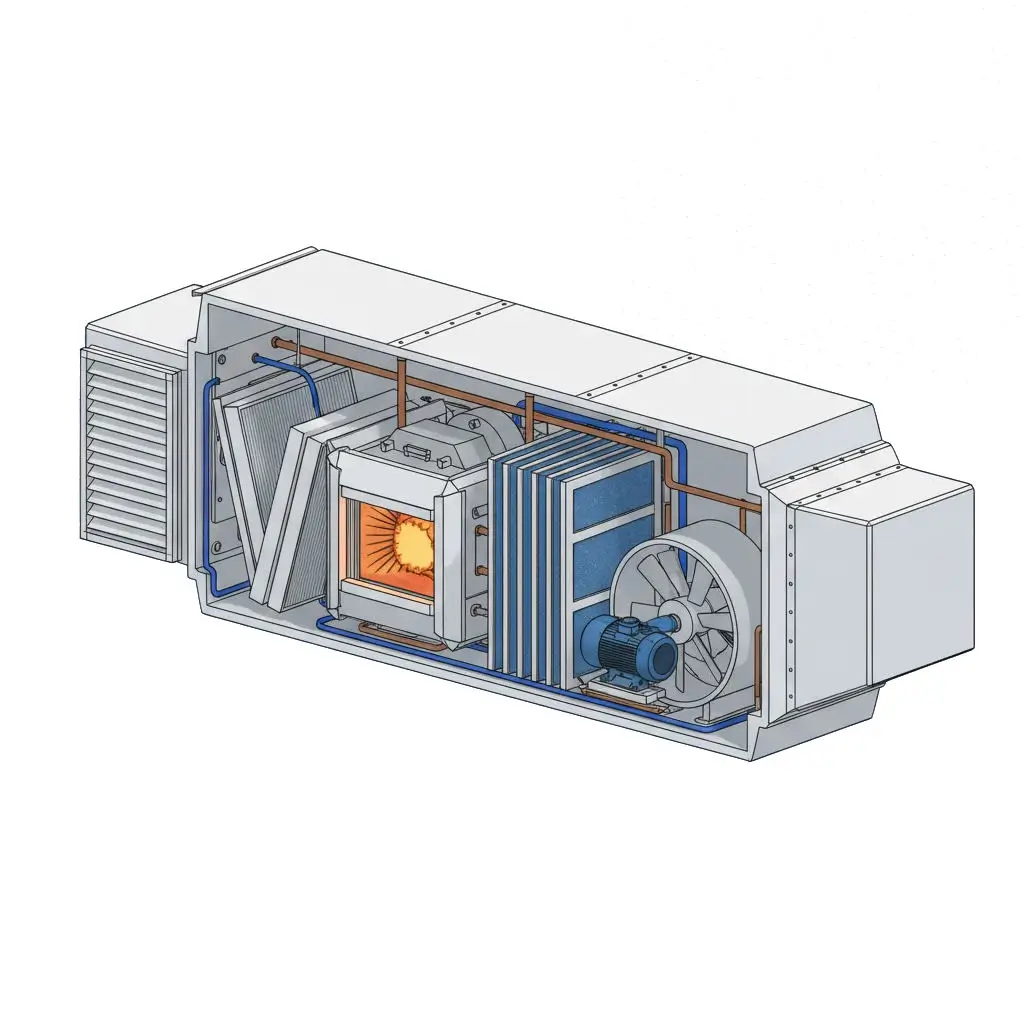

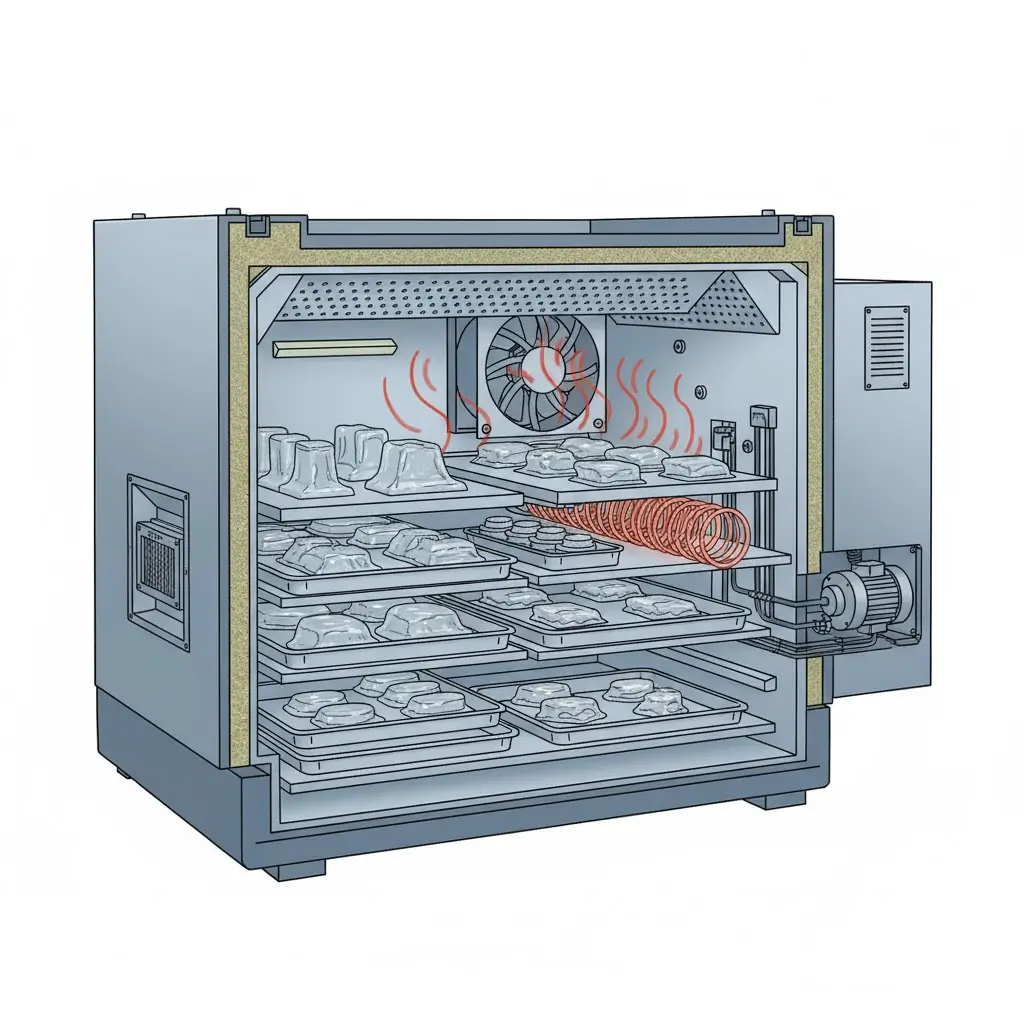

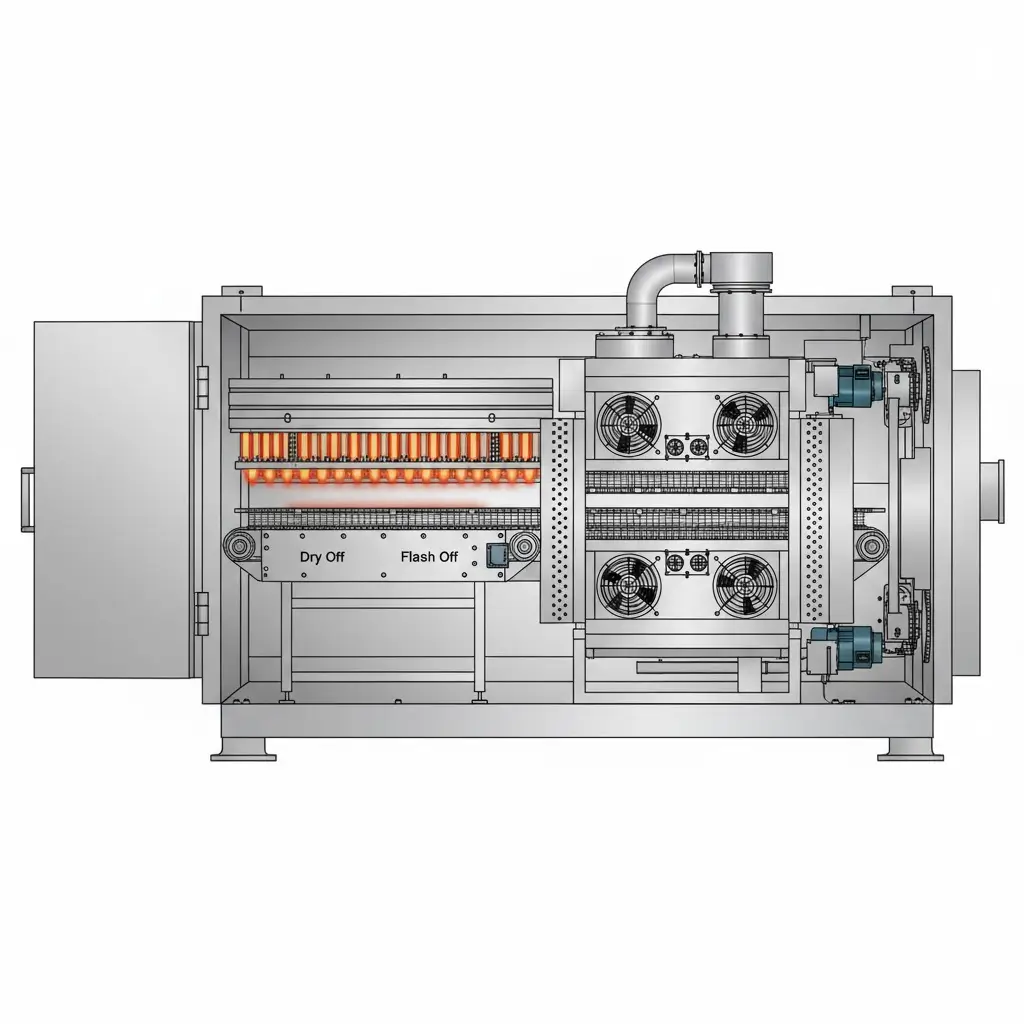

From e-coat and powder curing to IR drying tunnels and spray-booth heating, CD Automation delivers precision SCR/thyristor control for modern electric paint shops. Our REVO controllers help achieve stable temperature profiles, faster changeovers and auditable process data while supporting electrification goals.

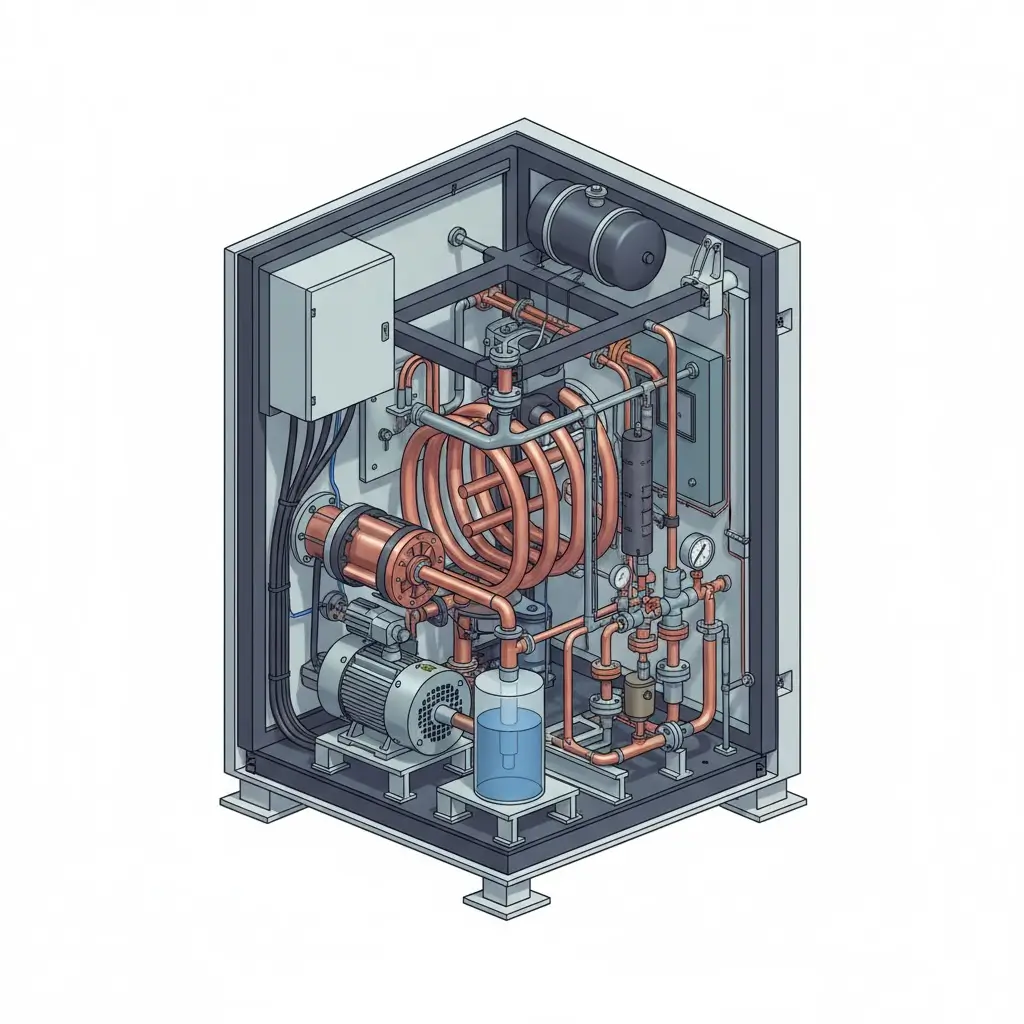

With advanced firing modes (burst, single-cycle, phase-angle), zone diagnostics and open communications via REVO-PC, REVO S, REVO C and REVO PB integrate seamlessly with PLC/SCADA systems to improve finish quality, line synchronisation and energy performance.

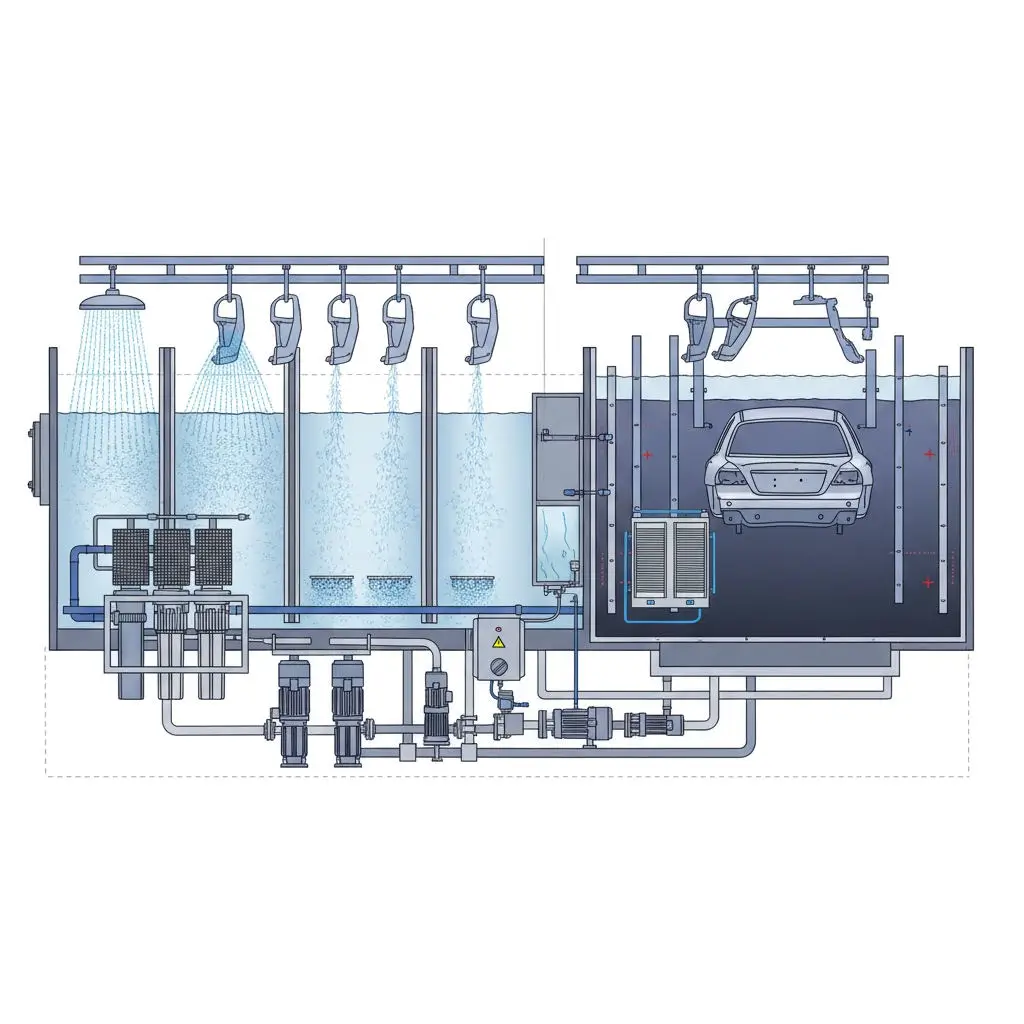

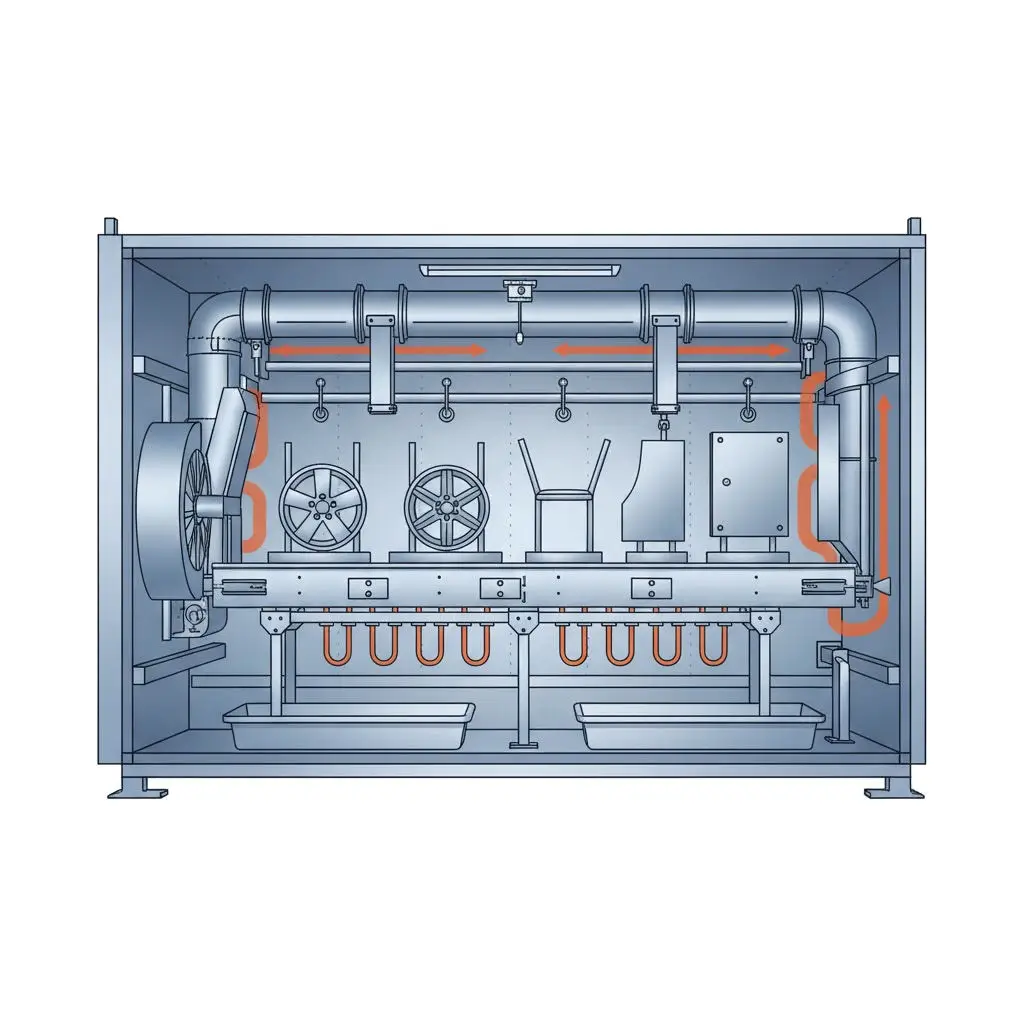

Automotive paint shops are adopting electric ovens and IR modules to enhance temperature uniformity, reduce emissions and improve energy efficiency. Intelligent thyristor power control enables coordinated multi-zone profiles, stable ramps without overshoot, and verifiable process data - helping OEMs and end-users raise finish quality and throughput while managing energy demand.