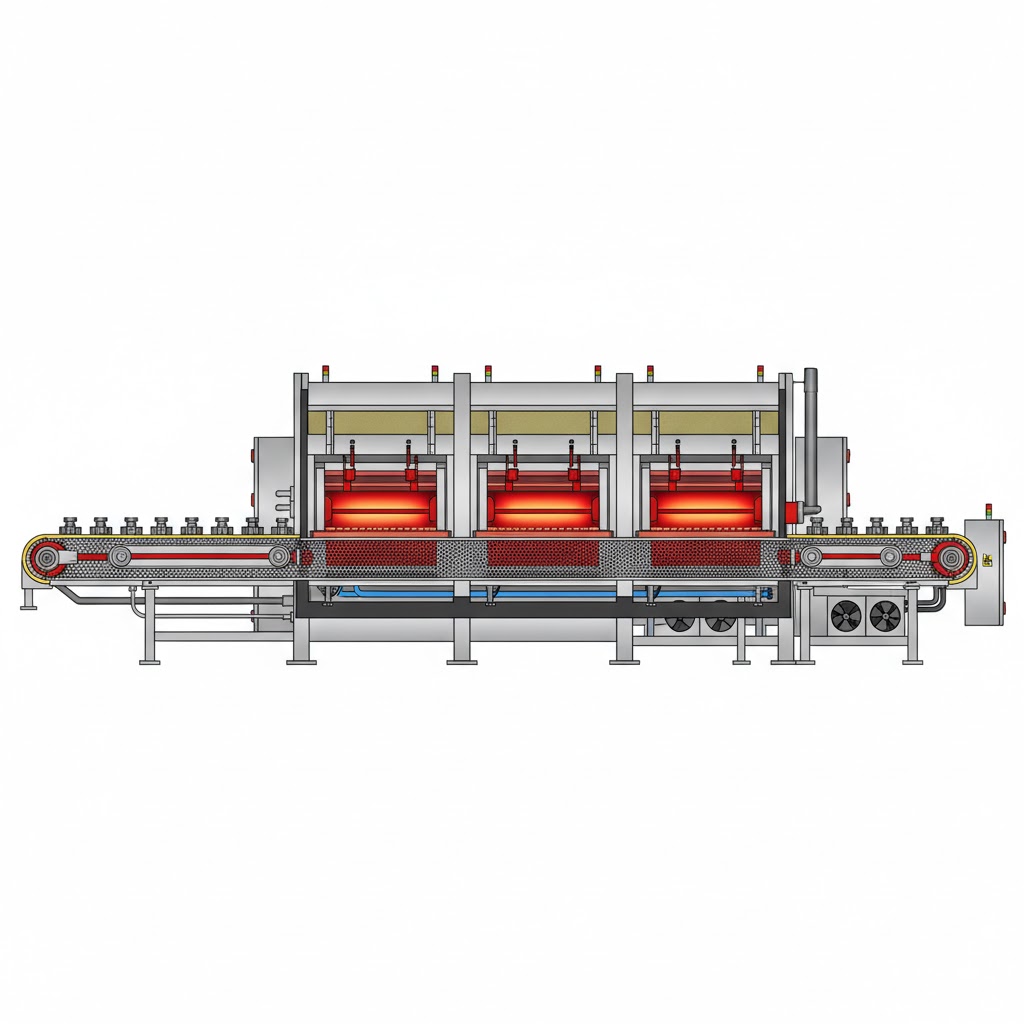

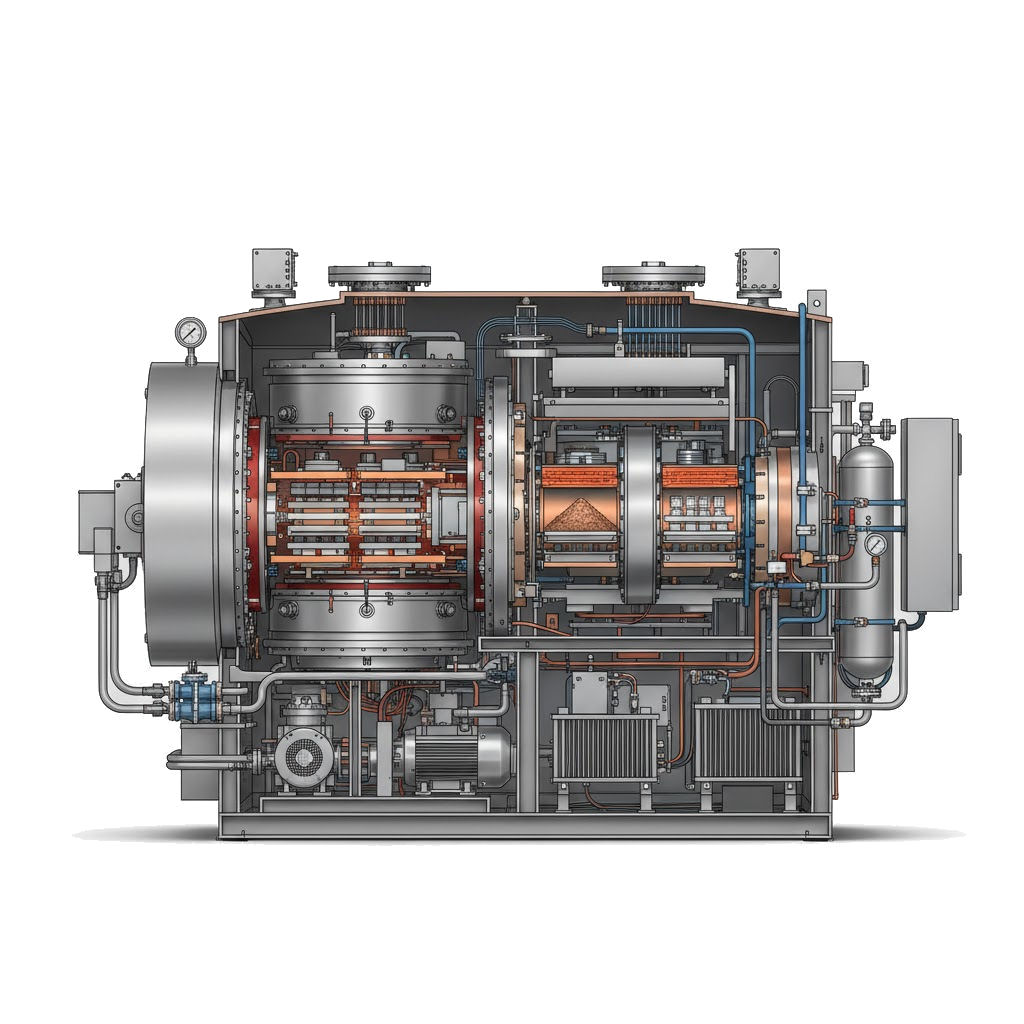

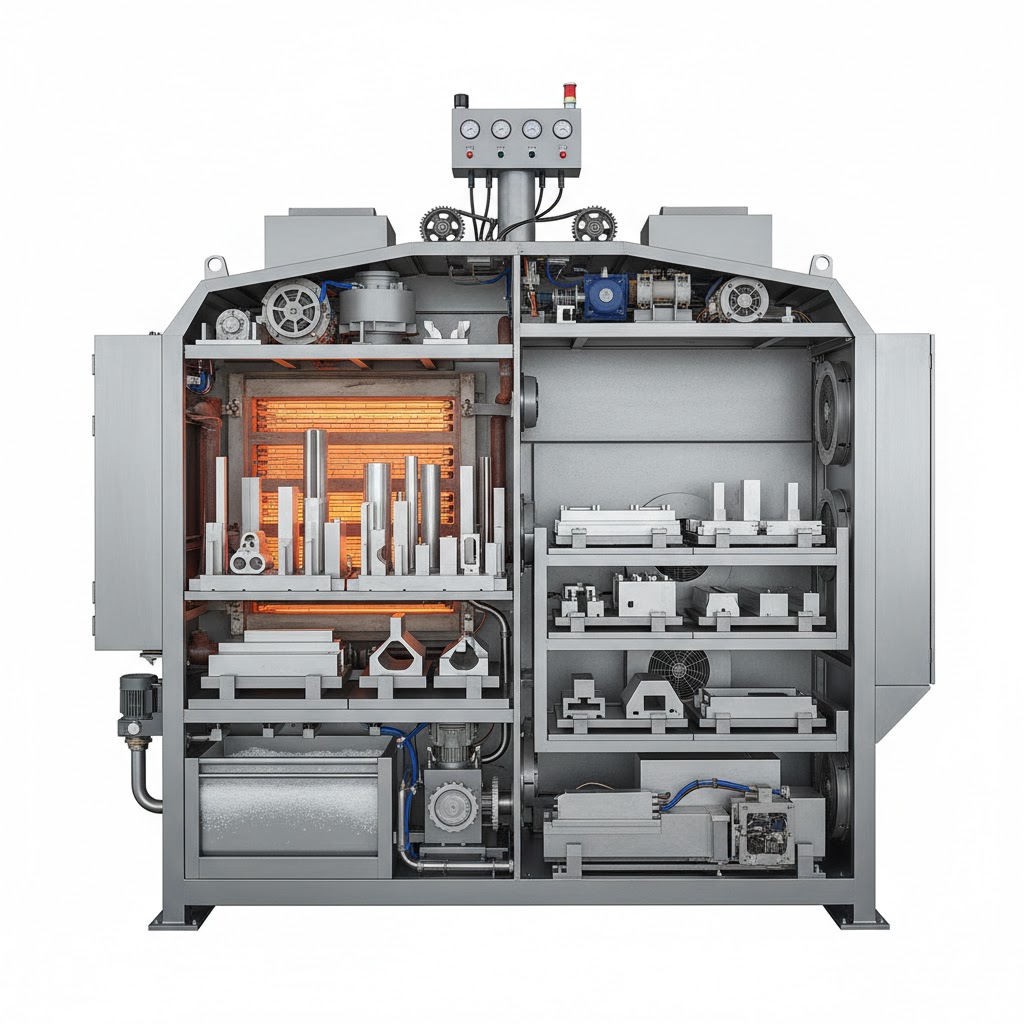

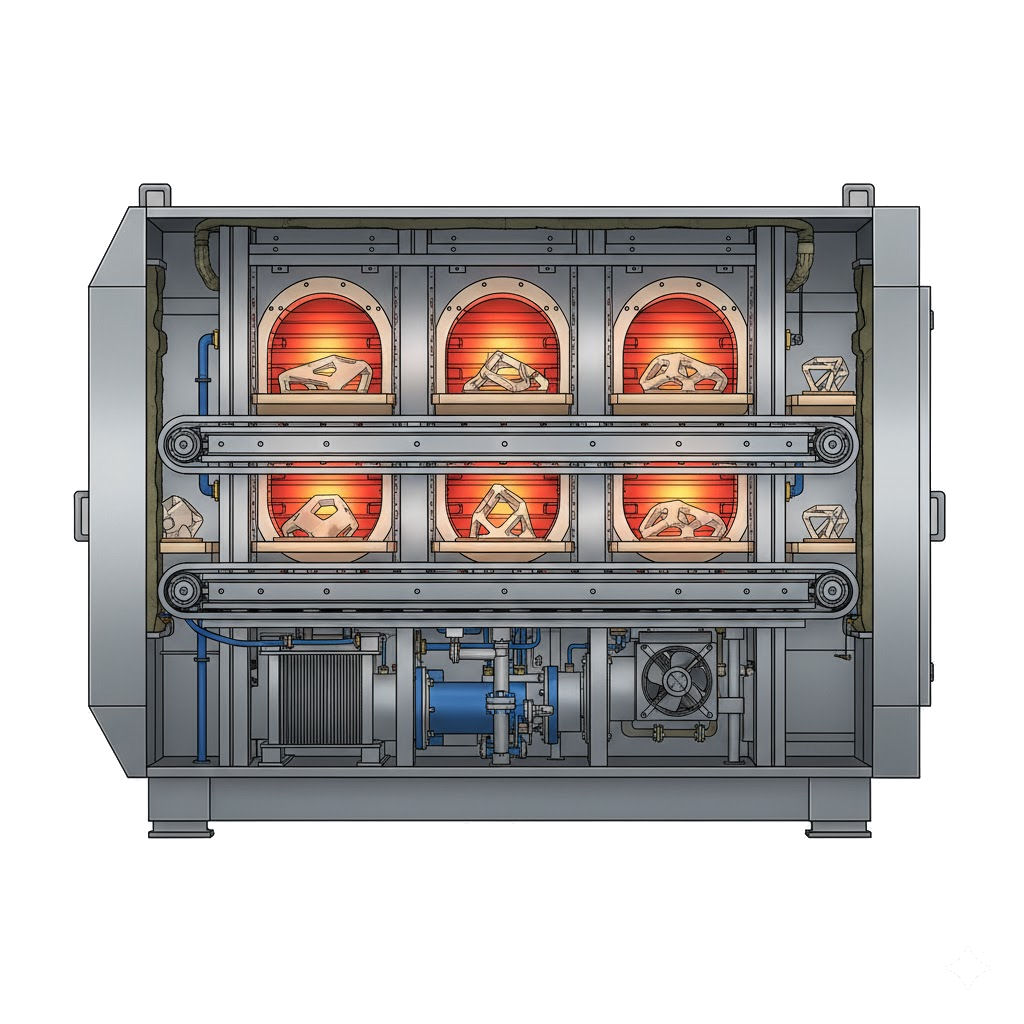

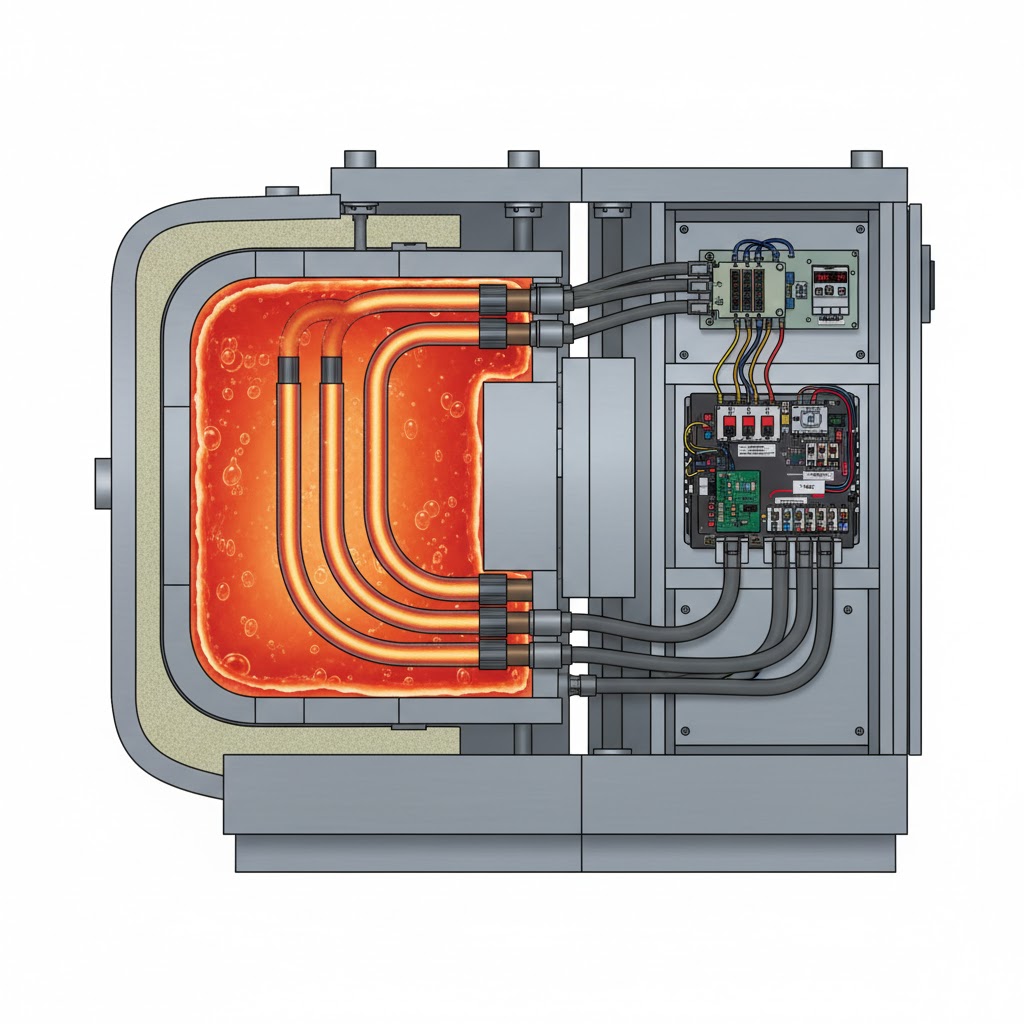

CD Automation provides SCR/thyristor power control for batch furnaces, conveyor lines, vacuum furnaces and aluminium T4/T6 ovens. Our REVO solutions help heat-treatment plants improve temperature uniformity, cycle repeatability and energy performance as they electrify or modernise existing equipment.

With REVO-S and REVO-C for single zones, REVO-PN for compact multi-zone systems, and REVO-PC, or REVO-DPU zone control on larger furnaces, we support everything from standalone furnaces to integrated lines with full PLC/SCADA connectivity.

Heat treatment furnaces increasingly use electric resistance heating for better temperature uniformity, easier profile control and reduced local emissions. Whether upgrading gas-fired assets or designing new all-electric lines, precise SCR power control is essential to achieve the required metallurgical properties while managing energy consumption. CD Automation’s REVO range underpins batch furnaces, conveyor lines, vacuum furnaces and aluminium T4/T6 systems worldwide.