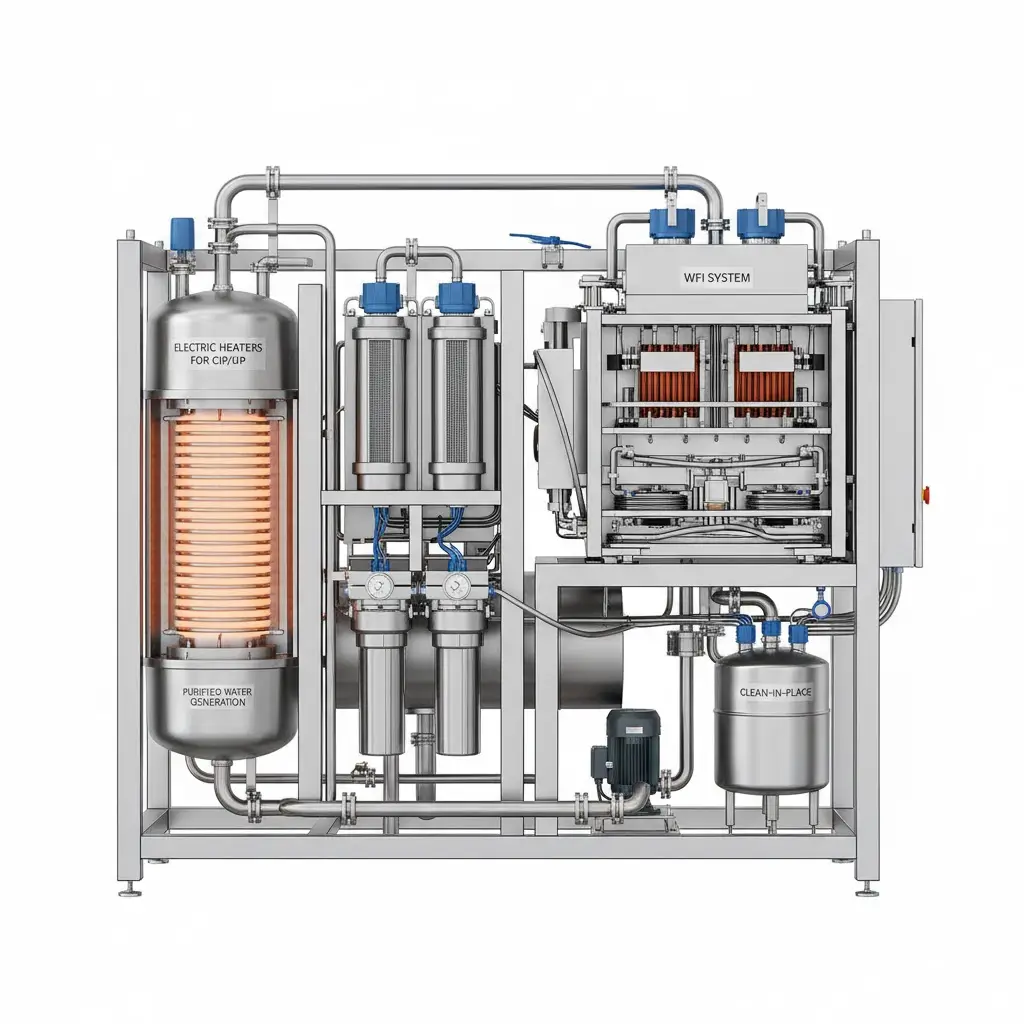

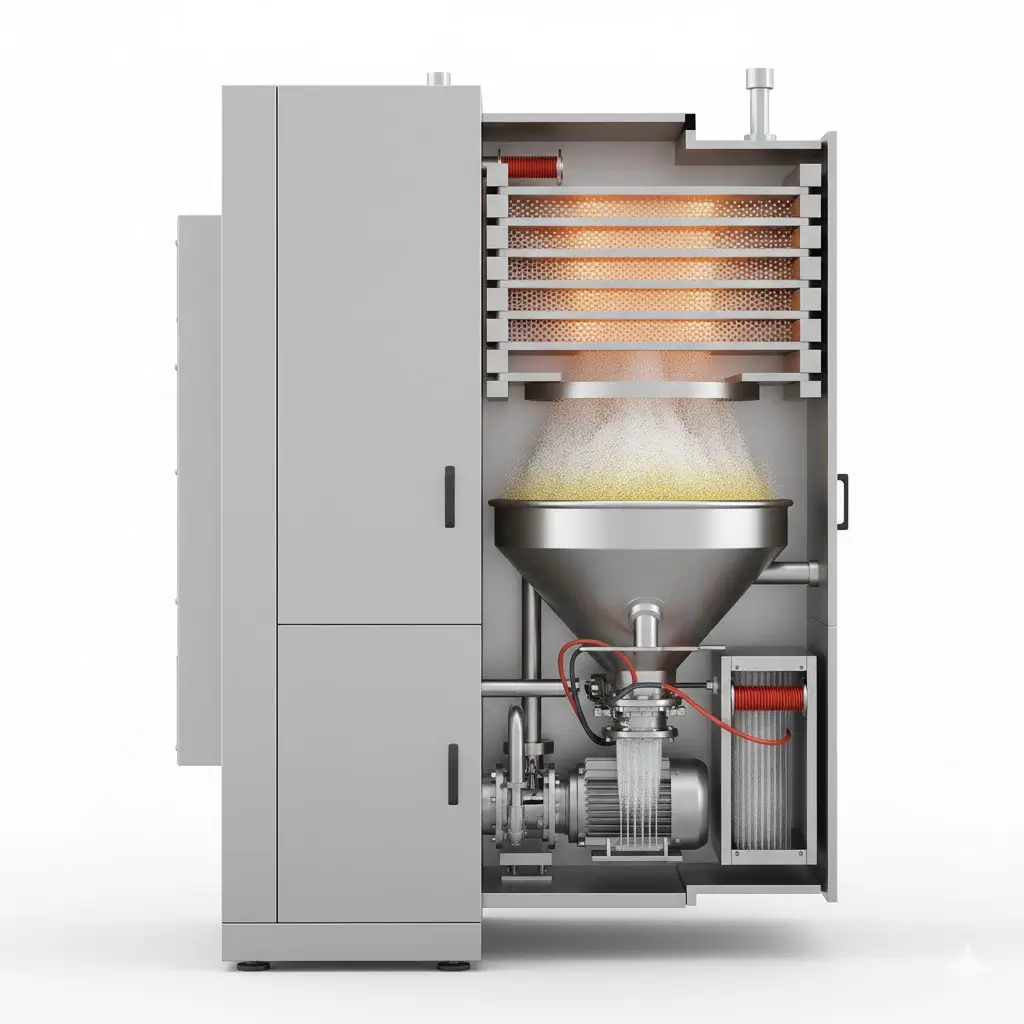

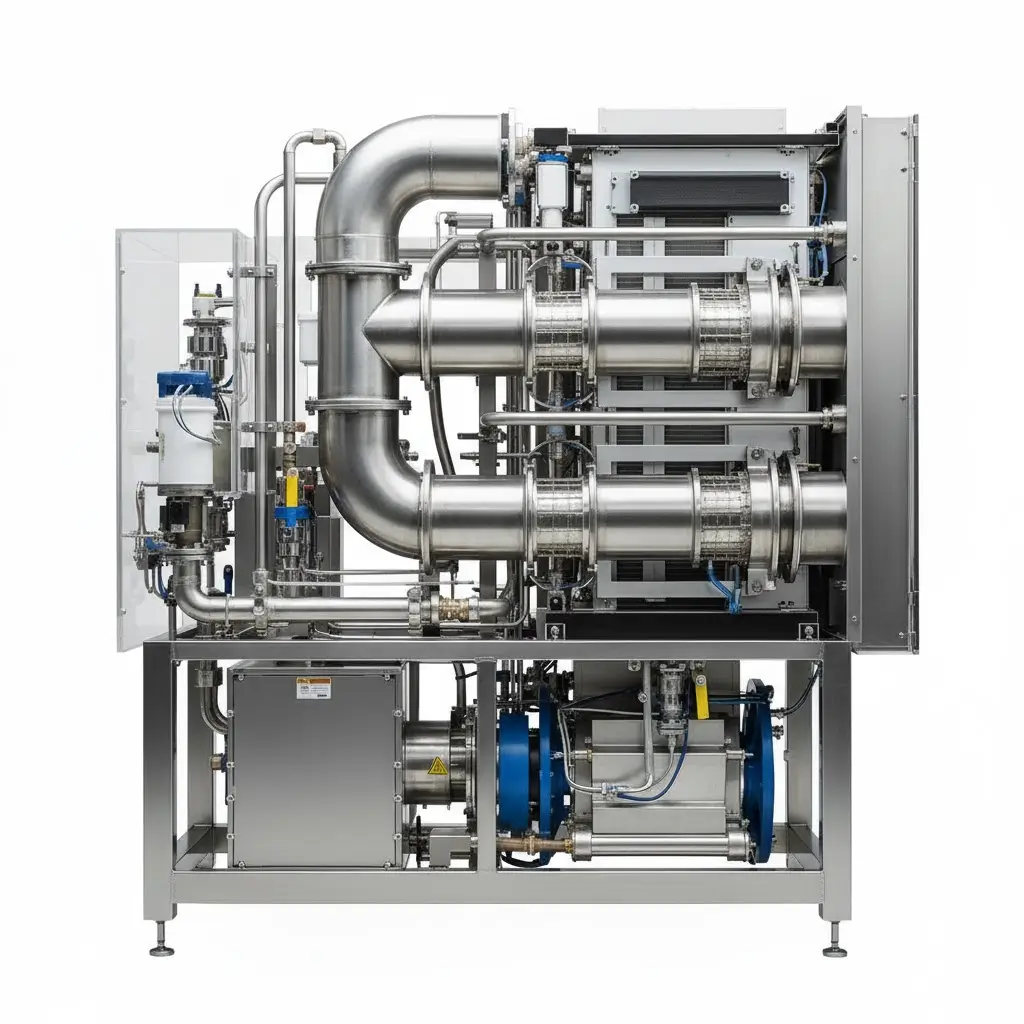

CD Automation supplies SCR/thyristor power control for pharma, biotech and fine chemical plants - from electric jacketed reactors and hot oil skids to CIP/SIP heaters, WFI systems and cleanroom air heaters. Our REVO controllers help deliver stable temperature control, support validation activities and improve energy performance across utilities and process equipment.

With REVO C for single zones, REVO-PN for compact multi-zone systems, and REVO-PC, or REVO-DPU zone control on larger skids and furnaces, we integrate easily with PLC, DCS and SCADA systems using common fieldbuses.

Pharmaceutical, biotech and fine chemical processes rely on accurate temperature control in reactors, dryers, distillation systems and critical utilities such as CIP/SIP and WFI. Electric heating is widely used where precise control, clean operation and fast response are important. Intelligent SCR power control improves stability, supports GMP compliance and helps sites manage their energy use as expectations on efficiency and sustainability continue to rise.