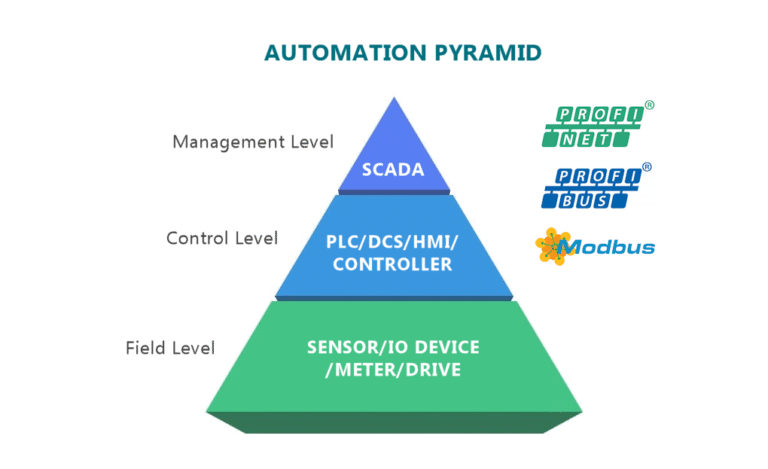

In today’s industrial landscape, the efficient and precise control of electrical power is critical for optimizing production processes, reducing energy consumption, and enhancing overall system performance. Thyristor power controllers, known for their ability to regulate electrical power with high precision, are increasingly integrated into plant systems. Utilizing advanced communication protocols such as Modbus®RTU, Modbus® TCP, Profibus®, and Profinet® can significantly enhance the effectiveness of this integration. This article explores the benefits of incorporating thyristor power controllers into plant systems using these modern communication protocols.

Thyristor power controllers are semiconductor devices that control the power delivered to an electrical load by adjusting the phase angle of the input voltage. They are widely used in applications requiring precise power control, such as heating, lighting, and motor speed regulation. Integrating these controllers into plant systems necessitates establishing reliable communication between the controllers and the plant’s central control systems, a task efficiently accomplished using Modbus RTU, Modbus TCP, Profibus, or Profinet protocols.

Modbus RTU (Remote Terminal Unit) is a serial communication protocol widely used in industrial automation. It operates on a master-slave architecture, where the master device initiates communication and the slave devices respond. Modbus RTU supports various serial communication standards like RS-232 and RS-485, making it a versatile choice for integrating devices over long distances.

Modbus TCP is an Ethernet-based version of the Modbus protocol, providing the same robust communication framework as Modbus RTU but with the added benefits of Ethernet technology. Modbus TCP enables faster data exchange and easier integration with modern network infrastructures, making it ideal for applications requiring higher communication speeds and real-time data processing.

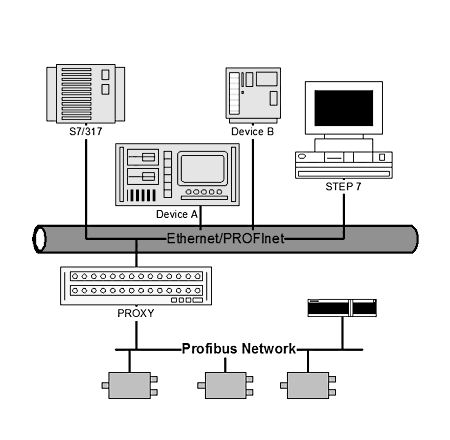

Profibus (Process Field Bus) is an open fieldbus standard for industrial automation, known for its robustness and reliability. It enables high-speed communication between controllers, sensors, and actuators. Profibus is available in two main variants: Profibus-DP (Decentralized Peripherals) for high-speed communication and Profibus-PA (Process Automation) for applications requiring intrinsic safety and process control.

Profinet is an advanced, Ethernet-based communication protocol designed for real-time industrial automation applications. It supports high-speed data exchange and seamless integration with IT systems, making it suitable for complex and large-scale industrial environments. Profinet offers two primary modes: Profinet IO for decentralized periphery devices and Profinet CBA (Component-Based Automation) for distributed automation systems.

Profibus and Profinet offer high-speed data exchange, ensuring real-time control and monitoring of thyristor power controllers. This rapid communication is crucial for applications requiring immediate response and precise control, such as manufacturing processes and energy management systems.

Modbus TCP, leveraging Ethernet technology, also provides fast communication speeds with the added advantage of easy integration into existing network infrastructures. Modbus RTU, while slower than Ethernet-based protocols, ensures reliable communication over long distances, making it ideal for distributed systems.

Integrating thyristor power controllers using these protocols allows for precise control over power delivery, reducing energy wastage and enhancing overall energy efficiency. The real-time data exchange facilitated by Profibus, Profinet, and Modbus TCP enables dynamic adjustments to power settings based on current demand, optimizing energy consumption. Modbus RTU also supports efficient power management through its robust communication framework, especially in distributed systems.

Fieldbus systems like Profibus and Profinet reduce the complexity of wiring by allowing multiple devices to communicate over a single cable, simplifying installation and reducing costs. Modbus TCP, leveraging standard Ethernet cabling, further simplifies integration, particularly in modern plant environments where Ethernet is the standard. Modbus RTU, using serial communication interfaces, offers straightforward integration with existing systems and reduces the need for extensive rewiring.

Advanced diagnostic features of these protocols enable quick identification and resolution of issues within the power control system. Profinet and Profibus offer detailed diagnostic information, such as device status and communication errors, which help in proactive maintenance and minimize system downtime.

Modbus TCP, with its Ethernet-based capabilities, allows for real-time diagnostics and remote monitoring, enhancing overall system reliability. Modbus RTU also provides diagnostic capabilities through its straightforward communication structure, facilitating efficient troubleshooting.

Fieldbus networks like Profibus and Profinet are highly scalable, allowing for easy expansion of the plant system by adding more devices without significant changes to the network infrastructure. This scalability ensures that the system can grow with the plant’s needs. Modbus TCP, with its Ethernet-based infrastructure, offers similar scalability, enabling easy addition of devices and integration into larger networks. Modbus RTU's master-slave architecture is also flexible, supporting the integration of multiple devices and enabling gradual system expansion.

These communication protocols support a wide range of devices from different manufacturers, ensuring interoperability and flexibility in system design. This interoperability allows plant operators to choose the best components for their specific needs, optimizing overall system performance. Standardization of protocols like Modbus RTU, Modbus TCP, Profibus, and Profinet ensures compatibility and simplifies integration across various platforms, enhancing the reliability and efficiency of the plant system.

Integrating thyristor power controllers using these protocols enables centralized control and monitoring of plant operations. This centralized approach enhances operational efficiency by providing a unified platform for managing all power control devices, facilitating better coordination and decision-making. Real-time data collection and monitoring capabilities, especially with Profinet and Modbus TCP, support predictive maintenance and system optimization, further improving the reliability and efficiency of plant operations.

Integrating thyristor power controllers into plant systems using Modbus RTU, Modbus TCP, Profibus, or Profinet protocols offers numerous benefits, including enhanced communication speed and reliability, improved energy efficiency, simplified installation and maintenance, and advanced diagnostic capabilities. These protocols also provide scalability, interoperability, and centralized control, making them essential for modern industrial automation. By leveraging these advanced communication technologies, industrial plants can achieve optimized performance, reduced energy consumption, and improved overall system reliability.

Contact our friendly support team to discuss your requirements and receive a no-obligation proposal that meets your specific needs.

Tel: 01323 811-100 or request a quote here.