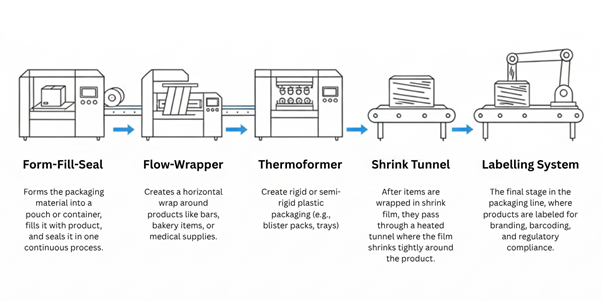

In today’s packaging industry, speed and precision are everything. But behind every efficient form-fill-seal machine, flow-wrapper, thermoformer, shrink tunnel, or labelling system lies a factor that too often goes unnoticed: how well the machine manages power and temperature. The truth is, even the most advanced packaging system can underperform – or stop altogether – if its power control isn’t optimised.

That’s where SCR (thyristor) power controllers and temperature controllers play a critical role.

The Hidden Cost of Poor Control

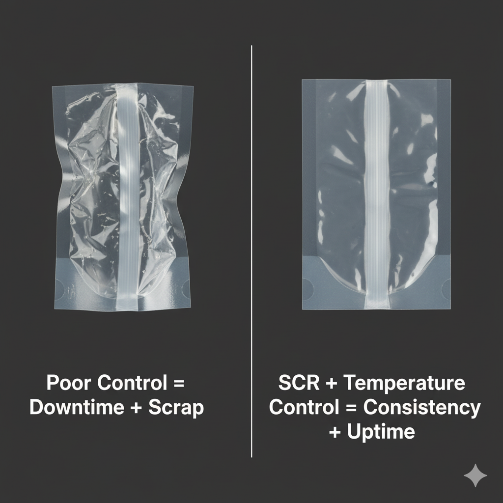

Packaging machines rely on precise heat delivery to form, seal, and protect products. If the heat fluctuates even slightly, seals can fail, leading to wasted materials, product rework, and in some cases, compliance risks.

Traditional mechanical relays often struggle to maintain this level of stability, especially under high throughput conditions in machines such as flow-wrappers or shrink tunnels.

The result? Inconsistent quality, unplanned downtime, and increased maintenance costs.

Studies in manufacturing environments have shown that unplanned downtime can cost up to 10x more than planned maintenance, both in lost production and in emergency repair. For packaging lines where every minute counts, this is an expense no one can afford.

Why SCR (Thyristor) Power Controllers Matter

SCR (thyristor) power controllers are designed to deliver precise, consistent power to heating elements, even under fluctuating loads. Unlike electromechanical relays, SCRs don’t wear out from repeated cycling. That translates into:

In short: with SCR (thyristor) power control, packaging machines—whether thermoformers, shrink tunnels, or labelling systems—run cleaner, faster, and longer.

The Role of Temperature Controllers

While SCRs provide the muscle, temperature controllers provide the brains. Advanced PID temperature controllers can monitor real-time conditions, adjust power instantly, and keep the process within tight tolerances.

For packaging operations, this means:

Together, SCR (thyristor) power controllers and temperature controllers form a closed-loop system that optimises heat delivery across all packaging equipment types.

The Bottom Line for Packaging Operations

The ROI of investing in modern power and temperature control is clear:

Packaging companies that prioritise this area see measurable gains in performance and profitability. As competition and regulatory demands increase, “good enough” power control simply isn’t good enough anymore.

Final Takeaway

If you’re looking to optimise your packaging line – whether in form-fill-seal, flow-wrapping, thermoforming, shrink tunnels, or labelling systems – start by looking at your power and temperature control systems. SCR (thyristor) power controllers and temperature controllers may not be the flashiest components, but they are the foundation of reliable, high-performing packaging machines.

At CD Automation, we offer a full and extensive range of SCR (thyristor) power controllers and advanced temperature controllers, all designed with durability in mind. Our power products come with an average lifespan of more than 10 years (MTBF) – a reflection of their robust design, superior components, and rigorous manufacturing and testing processes.

When you’re ready to explore how the right control solutions can help you minimise downtime and maximise throughput, let’s have a conversation.