SiC Element

Industry &

Applications

Silicon Carbide (SiC) Heating Element

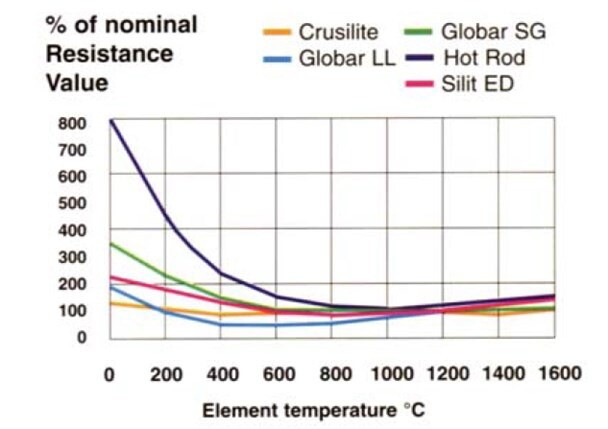

With this type of element the resistance changes over time. Elements that exhibit a large resistance change with age will benefit from Phase Angle Control. Silicon Carbide (GLO-BAR) is the most common element in this category. The resistance of this element can increase by a factor of four during its useful life.

Phase control is traditionally used with tapped transformers on this type of load so that the voltage may be varied to hold a consistent power output (see also transformer coupled loads). However our microprocessor based controllers can be programmed to hold constant output either by holding amps constant or by holding wattage (power) constant using feedback control.

When you work with Silicon Carbide Elements, what counts is the power (VxI). Working with VxI feedback, the unit will seek in all conditions to maintain the power required, from 0 to 100%.

With a new element you need to set the thyristors voltage and current settings (with actual values of the new resistance element), then automatically as the elements age the power feedback increases the voltage to maintain the required power. This is because as the elements age, their resistance increases resulting in a decreasing current. At this point the unit automatically increases the voltage to maintain the required power.

During the start-up, when the elements are cold, they have a high resistance, so we must limit the voltage to avoid ‘supercharging’ the elements. However, there is a problem of limiting the power during the start-up, when the elements are still cold.

In this situation when the resistance of the elements are high, the power feedback will try to increase the voltage to obtain the required power. It is therefore necessary during the initial phase of heating that you work with Voltage feedback, limiting the voltage then move on to power feedback during normal operation.

If using a temperature controller to switch the thyristor, the easiest way is to use an external alarm set above 500 deg. C to trigger the configurable input of the thyristor unit from Voltage to Power feedback.

SiC Touch Panel

CD Automation has developed many applications dedicated to drive particular loads and one of these application is for Silicon Carbide. Our aim is to use standard thyristor power controllers with serial communication but to implement the control strategy inside the in-telligent panel.

This ‘SiC Touch Panel’ used with a CD Automation universal power controller can work with all firing and control modes removing all possible application risks for the user.

A simple and effective solution to control Sic elements

- Can be connected to ‘off-the-shelf’ readily available thyristor units

- An external port is available to connect to your PLC

- One Ethernet port is available on 8″ touch panels

- Easy to set-up and start working almost out the box

Two different modes to drive SiC:

- Burst Firing with automatic adjustment of power limit

- Phase Angle with transfer from voltage to power control mode.

Features

- Automatic configuration and tuning of the thyristor unit

- Automatic tuning of power control mode VxI

- Local message indication to tell you when to change the elements due to end of life

- Automatic switch from voltage to VxI control mode when the correct element temperature is reached

- Automatic tuning procedure of heater break alarm to diagnose partial or total load failure

- Provides indication of fuse failure or thyristor in short circuit

- Recent and Historical Curve of following process variable

- Power density W/Cm2