Infrared Lamp

Industry &

Applications

Short Wave Infrared Lamps

With infrared lamps heat transfer is easy. It requires no contact with the material and no intermediate such as air or water. High power can be transmitted; foils, plates and other material are heated in seconds.

There are a number of infrared types, the most common being short, medium & long waveform. Medium and long wave infrared lamp applications can be treated as a standard resistive load with no additional considerations.

Short waveform is altogether different, with peak currents between 7 and 16 times the nominal process current. To compensate for this, thyristors are normally oversized with single cycle the preferred choice of firing.

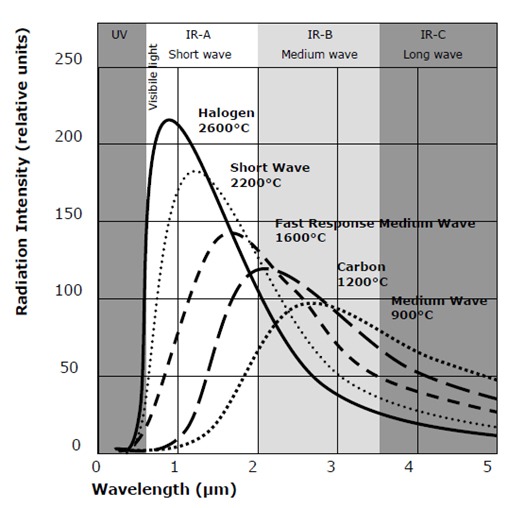

The emitter temperature determines the special distribution of the wavelengths. In the above example, with decreasing temperature, the spectrum shifts to the longer waveforms.

Just like visible light, part of the broad spectrum of the IR radiation is reflected from the surface of the material, part is absorbed within the material and part penetrates through the material. The reflected component is usually very small.

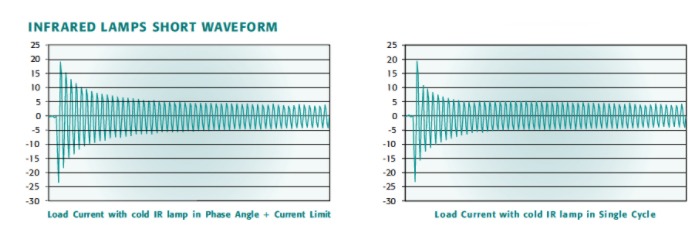

Short Wave Infrared (SWIR) lamps can be driven with different firing types: Single Cycle, Burst Firing and Phase Angle with Current Limit.

The graph above demonstrates how the inrush current remains high for a longer period if we use Phase Angle plus current limit, than with say Single Cycle.

Single Cycle technique is the most used to drive infrared short waveform. During the OFF time the SWIR elements become cold (due to their low inertia) with a resulting current peak when switched ON again. This current peak is a function of the number of Burst Firing cycles, for this reason the OFF time must be as short as possible to reduce this current peak. Phase Angle firing is not used because the supply voltage is normally less than nominal and therefore the elements never reach the working temperature.

So to summarise:

- short waveform: current peak can be 7 times the nominal current so the thyristor must be sized correctly

- ultrashort waveform: current peak can be 16 times the nominal current so the thyristor must be sized correctly

- medium waveform: current peak is equal to nominal current so no special attention needed

- fast medium waveform: elements are tungsten and can be considered as short waveform but the current peak is lower with a longer heating time, which can stress the thyristor semiconductors. Contact the sales office for further information.

- long waveform: current peak is equal to nominal current so no special attention needed

Care must also be taken with short-wave lamps that require very low voltages. This is a typical requirement in the motor industry and with the paint spraying/curing process.

Special thyristor sizing considerations must be made as the voltage supply can be lower than nominal values causing a lower peak but a very long overcurrent that can stress the thyristor semiconductors. Contact your nearest CD Automation outlet with your SWIR lamp specifications for help in sizing the correct thyristor power controller.

Typical infrared applications include the forming and processing of:

-

- plastics

- paper

- glass

- wood

- metals

- printing

- pharmaceutical

- electronics

- food

- chemical

- ceramics

- tobacco

- air conditioning

Product Suggestion:

For single phase loads we suggest REVEX 1PH for currents up to 210A, or REVO-C 1PH.

For 3 phase loads we recommend REVO-C 3PH.