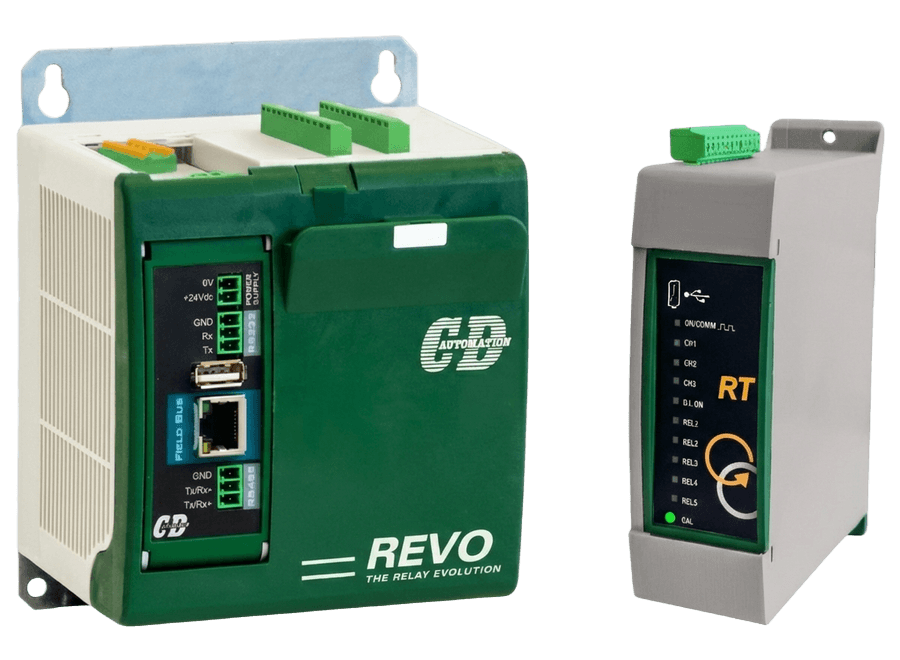

A modular, multi-loop temperature control platform for electrically heated machinery, built for OEM integration, predictable thermal stability and simplified panel engineering.

REVO RT Loop is designed to replace traditional panel-mount temperature controllers or reduce PLC PID loop complexity by consolidating multi-zone temperature control into a modular back-panel system.

SKU: REVO-RT

REVO RT Loop addresses these challenges by consolidating multi-zone PID control into a modular platform with structured diagnostics and predictable integration.

Choose 3, 6 or 9 loop modules and scale branches to match machine architecture. This reduces repeated panel-mount hardware and supports consistent loop deployment across platforms.

Designed for modern automation architectures with industrial comms options (Modbus RTU/TCP and common fieldbus/industrial Ethernet variants depending on configuration).

From compact machines to large multi-zone systems, REVO RT Loop supports structured scaling without redesigning the control concept each time.

Communication options may include Modbus RTU, Modbus TCP, and industrial Ethernet / fieldbus variants depending on selected configuration.

Standardise a single multi-zone control architecture across machine variants to reduce engineering time and improve repeatability in production.

What to include in your enquiry