✔ Stop juggling dozens of standalone controllers for each heating zone

✔ Eliminate power peaks and flicker caused by uncoordinated firing

✔ Locate heater and SSR faults in minutes, not hours inside a hot cabinet

SKU: Multi-Zone

On paper, your current architecture works: a temperature controller and power unit for each zone, wired back to the PLC. In reality, it’s creating problems you feel every day.

Panels full of hardware and wiring

Every new zone adds a controller, SSR, fuse, terminals and documentation. The result is a cabinet that’s crowded, complex and difficult to maintain.

No coordination between zones

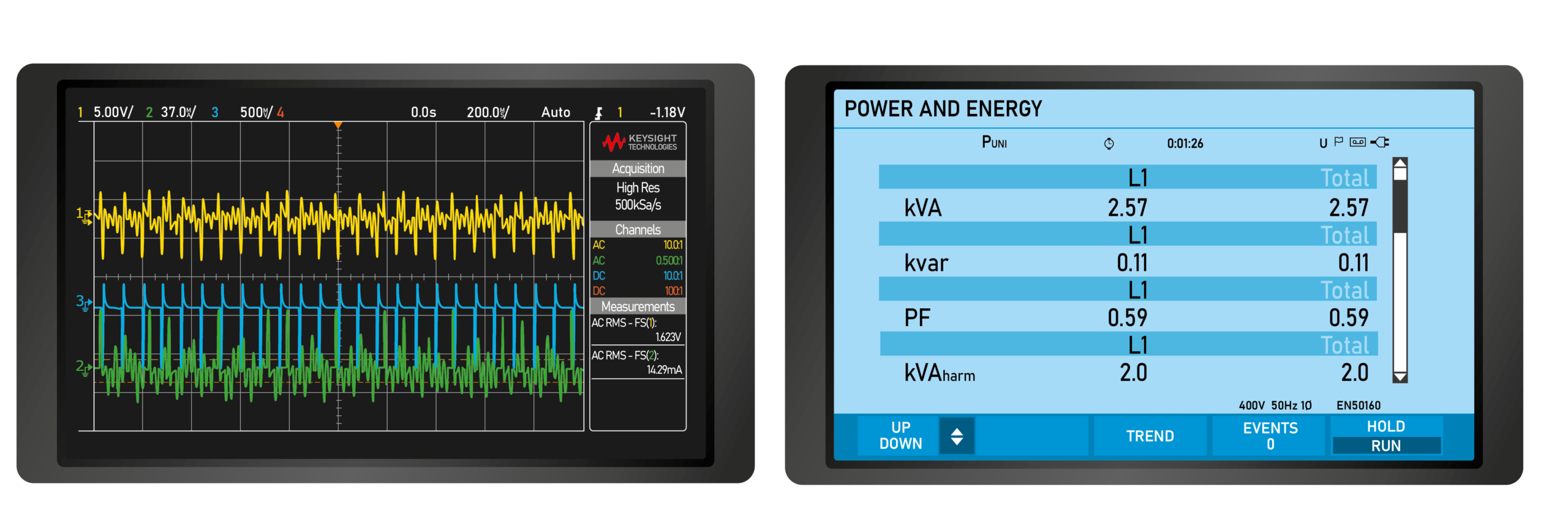

Each zone fires “when it needs to”, with no understanding of what the other zones are doing. That means unpredictable current peaks, flicker and harmonic distortion.

Painful fault-finding & energy pressure

A single failed heater, SSR or fuse can take hours to locate. Meanwhile, energy teams demand better power factor and controlled peak demand.

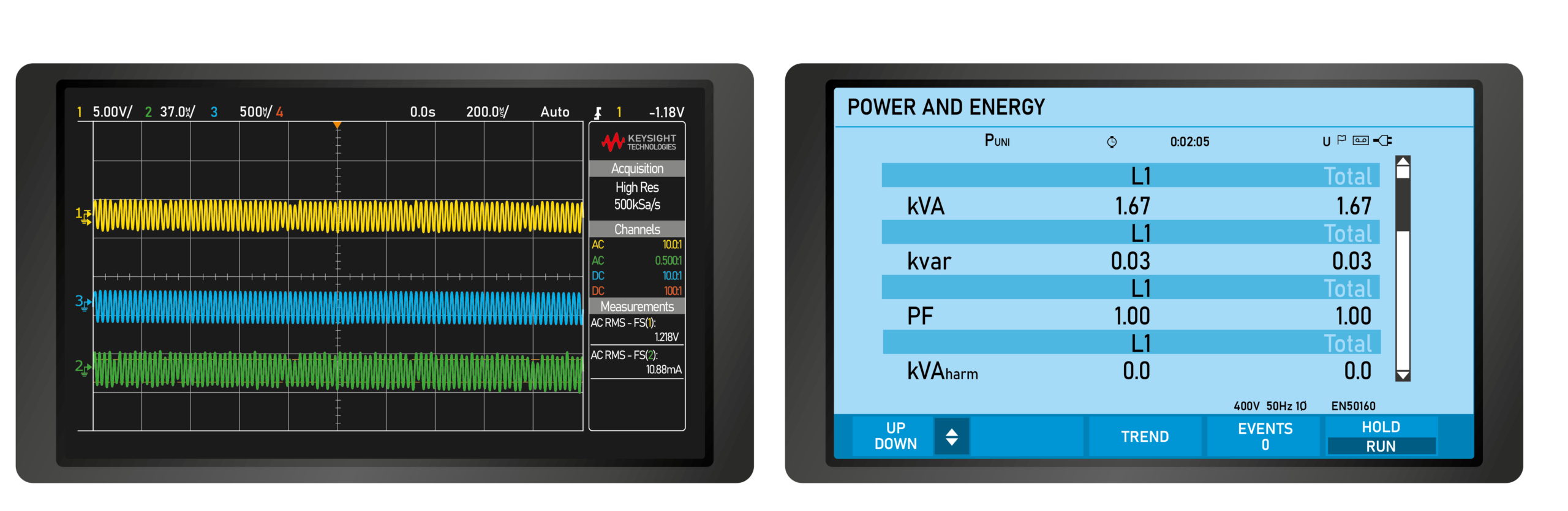

Power optimisation on REVO PC is designed for multi-zone heating systems where many loads operate simultaneously. Using synchronised Dynamic Burst Firing, REVO PC coordinates all zones so total line current remains as constant as possible, rather than allowing random current peaks. This intelligent distribution of power reduces unnecessary losses, lowers peak demand and ensures only the real power required by the process is drawn from the supply.

The result is significantly improved power quality: power factor is maintained close to unity, harmonic components are minimised and voltage disturbances such as flicker and dips are greatly reduced. For the customer, this means lower energy costs, reduced stress on cables and transformers, improved network stability and reliable operation without the need for external power-factor correction or harmonic filtering.