In extrusion lines, barrel heaters operate across multiple zones to maintain a stable thermal profile. Even small fluctuations in barrel surface temperature can influence polymer viscosity, particularly when processing filled, recycled or temperature-sensitive materials.

On/Off switching introduces cyclic power delivery:

Although thermocouples may report stable average temperatures, the steel barrel experiences micro thermal ripple. This ripple affects heat flux into the polymer melt, contributing to:

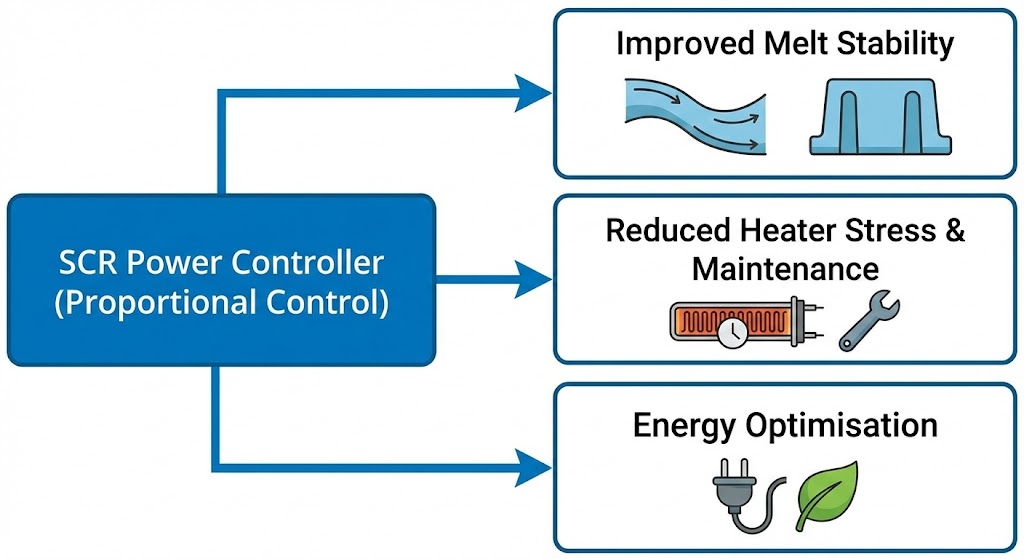

An SCR power controller regulates electrical power proportionally rather than switching heaters fully on and off. This reduces thermal oscillation and improves melt consistency.

The consequences include:

Over time, these small variations accumulate as scrap, rework and extended stabilisation periods.

Injection molding machines typically use multiple barrel zones and, in some cases, hot runner systems. Stability during plasticising and shot preparation is essential for consistent part weight and surface quality.

Mechanical contactors introduce:

Basic SSRs eliminate mechanical wear but still provide full on/off switching.

A thyristor (SCR) power controller modulates the AC waveform using burst firing or phase-angle control. This allows smooth, proportional energy delivery matched to process demand.

For injection molding applications, this results in:

Modern extrusion and compounding systems may contain 6 to 20 heating zones. Coordinating these zones effectively is essential for stable melt flow.

Advanced SCR power control systems allow:

In multi-zone configurations, master-coordinated architectures such as REVO-PC can manage simultaneous load start-up, protecting transformers and improving electrical stability.

Reducing thermal ripple across zones improves:

Electric heating in extrusion and injection molding is often the largest continuous electrical load within a plastics processing plant. In multi-zone barrel systems, uncontrolled cold start and basic on/off switching can create sharp load spikes, increasing maximum demand charges and placing stress on transformers and supply infrastructure.

For UK manufacturers operating under contracted kVA agreements, reducing peak demand in a plastics plant can provide measurable energy cost savings without reducing production output.

Traditional contactor or zero-cross switching applies 100% heater power during each cycle. When multiple zones energise simultaneously, particularly during cold start, the combined current draw can produce significant peak demand across the three-phase supply.

Industrial SCR power controllers reduce this effect by proportionally regulating power according to thermal requirement. Rather than repeatedly applying full load, power is modulated to maintain temperature stability while smoothing current draw.

In multi-zone systems this enables:

Integrated Heater Bakeout functionality further enhances controlled start-up. When heaters have absorbed moisture during shutdown, a gradual low-power sequence safely dries the elements before full operating load is applied. This reduces inrush current, stabilises insulation resistance and limits unnecessary peak loading during restart.

Energy efficiency in plastics processing is not only a mechanical consideration. The method used to control electric heater power directly influences peak electrical demand, infrastructure stress and long-term operating cost. Coordinated SCR power control therefore supports both melt stability and electrical cost optimisation within a modern plastics plant.

Frequent heater replacement is common in extrusion and injection molding plants. However, heater failure is not always due to element quality.

Full on/off cycling increases:

Proportional SCR control reduces electrical stress by smoothing energy delivery and limiting current peaks during start-up.

Integrated current monitoring and partial load detection allow early identification of degraded heaters before catastrophic failure occurs. This supports predictive maintenance strategies and reduces unplanned downtime.

SCR power controllers typically operate in two primary modes:

Burst firing (zero-cross control):

Phase-angle control:

Selecting the correct firing strategy depends on machine design, heater configuration and process sensitivity.

In plastics processing, melt behaviour defines product quality. Electric heating should not be treated as a basic utility function.

Upgrading from contactor or SSR-based control to industrial SCR power controllers can improve:

For plants focused on reducing scrap, improving OEE and managing energy cost, electric heater control is a measurable and optimisable variable.

As plastics manufacturers pursue tighter tolerances, recycled material integration and higher productivity, melt stability becomes increasingly critical.

Industrial SCR power controllers provide precise electric heater control for extrusion, injection molding and compounding systems. By reducing thermal ripple, balancing multi-zone loads and protecting electrical infrastructure, advanced thyristor technology improves process reliability and product consistency.

For processors evaluating upgrades to their heating control systems, a technical review of existing power delivery strategy can often identify measurable improvement opportunities without major mechanical modification.

If you operate extrusion, injection molding or compounding equipment and are evaluating improvements in melt stability, heater reliability or energy performance, reviewing your electric heater control architecture is a practical first step.

CD Automation specialises in industrial SCR (thyristor) power controllers for plastics processing applications, including:

Our engineering team can assess your existing heating control system and advise on:

Improving melt stability does not always require mechanical redesign. In many cases, upgrading the power control strategy delivers measurable improvements in process consistency and heater lifespan.

Further information on plastics & polymer processing can be found on our Industry page here.

Or contact our engineering team to assess your current heating control strategy.

Click the link in the page footer below to ‘Book a telephone callback’, or click the ‘Contact Us' button to request a no-obligation quotation, or simply ask a question. We're here to help.