Temperature control technology is crucial for industries to maintain quality and efficiency. In this article, we’ll explore its importance, recent trends, and applications in fields like food processing and manufacturing.

From the crisp bite of a fresh apple to the robust functionality of aerospace components, temperature control is the essential force ensuring safety, quality, and efficiency. This key aspect of industrial success supports many sectors, using temperature control systems to manage the precise conditions needed for product integrity and longevity.

In the complex world of industrial processes, temperature controllers are reliable tools that maintain the exact temperature ranges necessary for advancements in science, technology, and food production.

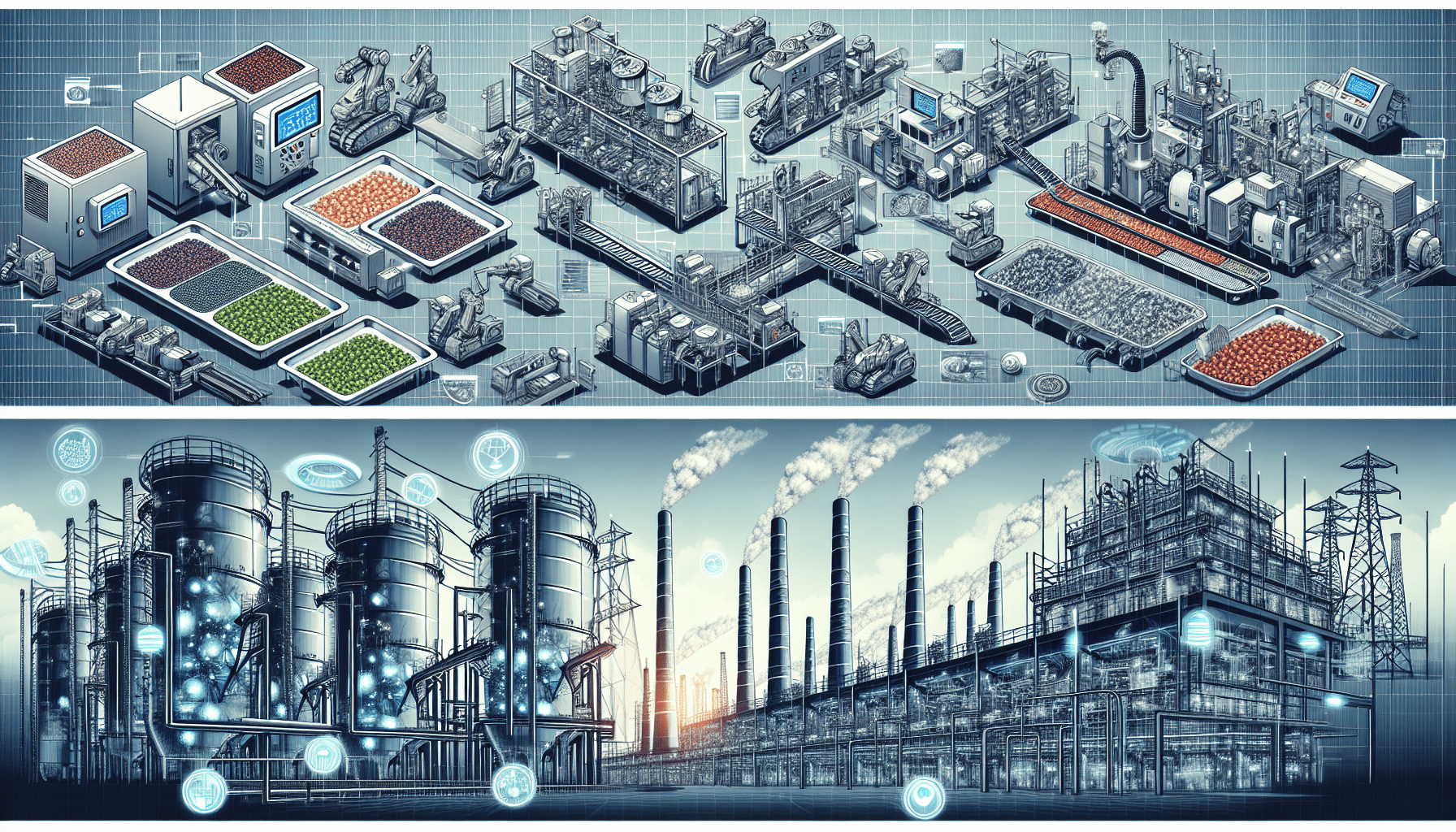

In food processing, getting the temperature right is critical. Even small mistakes can make the difference between delicious and dangerous food. Accurate temperature control is essential to prevent harmful microbes from spreading. This not only preserves the flavours and textures we enjoy but also ensures that we meet strict safety standards.

Careful monitoring and control of temperature are fundamental to both the art of creating great food and guaranteeing public health.

Moving from the kitchen to the factory floor, temperature control continues to play a vital role. In manufacturing, precise temperature control maximizes material properties and minimizes waste. Accurate temperature regulation turns raw materials into high-quality goods through efficient production processes, leading to better financial results and customer satisfaction.

Temperature control technology is crucial in power plants. It helps prevent equipment damage and operational halts that could lead to costly shutdowns.

Advanced temperature control systems act as vigilant protectors. Their sophisticated diagnostics can predict and prevent sensor failures, saving significant costs. These systems ensure optimal temperature management, keeping operations running smoothly.

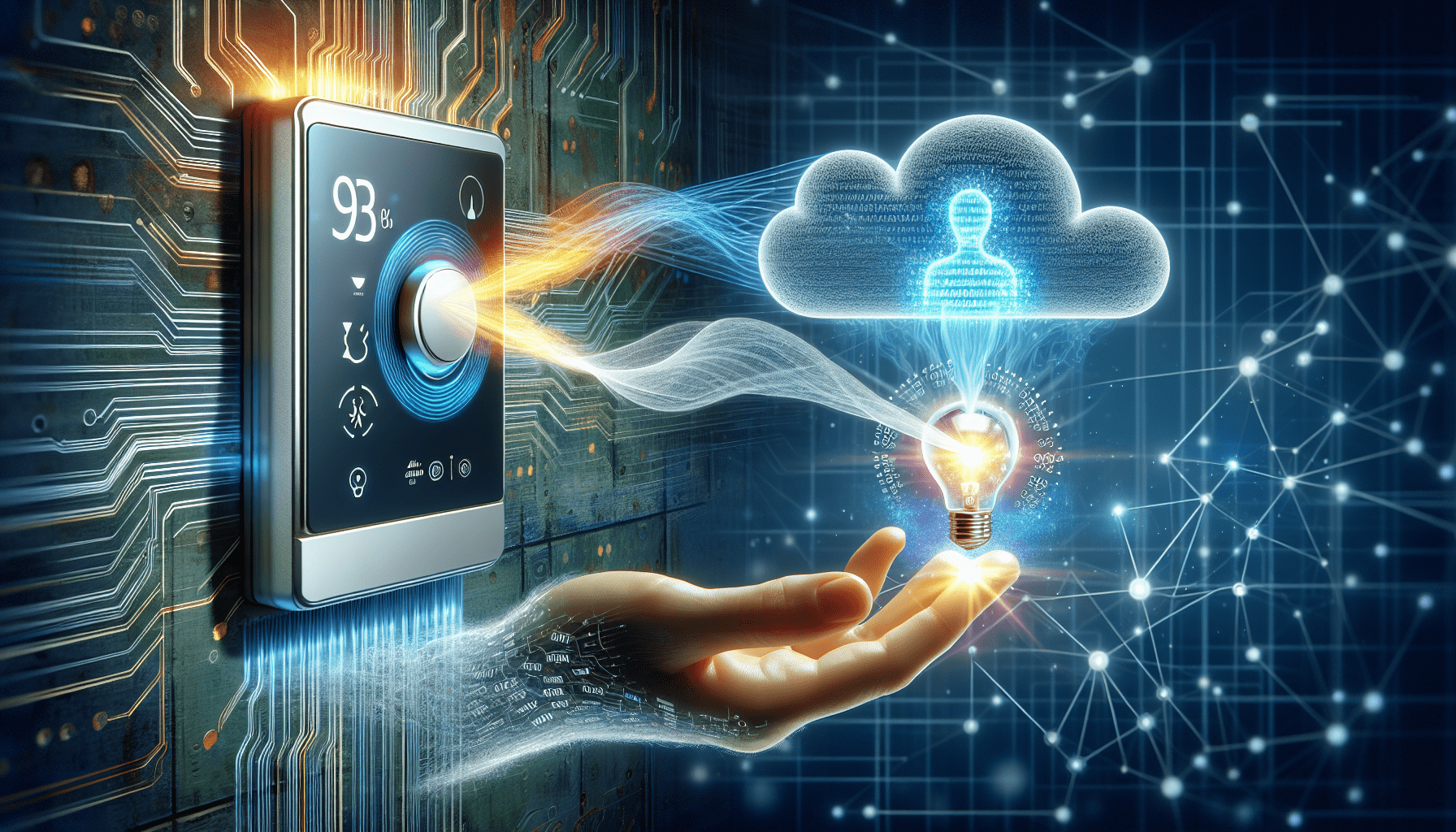

In a world where innovation is constant, temperature control technology is evolving rapidly. Breakthroughs in artificial intelligence, data analytics, and cloud computing are making temperature control more accurate, efficient, and connected.

Staying updated with these advancements is crucial for optimal performance.

AI and machine learning are transforming temperature control systems. These technologies help systems learn and adapt to changing conditions, improving accuracy and efficiency. For example, AI can optimize energy use and adjust settings based on weather forecasts.

New sensors and data analytics provide greater precision and foresight. Advanced sensors collect detailed environmental data, which algorithms use to optimize system efficiency. Predictive maintenance is now possible, shifting from reactive to proactive approaches.

Cloud computing and wireless communication enable remote monitoring and control. IoT sensors integrated with cloud platforms allow adjustments from anywhere, ensuring ideal conditions are maintained continuously.

Navigating the landscape of temperature controllers reveals a wide range of devices designed for various applications. These systems use inputs from sensors and thermometers to control heating or cooling elements, ensuring the desired temperature is reached and maintained.

On-off temperature controllers are simple devices that switch between on and off states to maintain a set temperature. While they don't offer precise control, their simplicity is beneficial in environments where exact precision isn't necessary.

Proportional temperature controllers provide more refined control by adjusting their output based on how close the temperature is to the setpoint. This method reduces the fluctuations seen with on-off controllers, offering more stable and consistent control for sensitive applications. A proportional controller can significantly improve precision.

PID temperature controllers offer the highest level of precision by combining proportional, integral, and derivative functions. These controllers learn from past performance and continuously adjust their output to maintain the desired temperature accurately.

The pursuit of the ideal digital temperature controller is about finding the right fit for your needs. Choosing the right one means understanding the specific requirements of your application. From the type of input sensor to the range of temperatures, various factors must align to ensure the controller meets your process's demands.

When selecting a digital temperature controller, consider the following:

These factors are crucial for ensuring the controller works well with the control element and the environment.

Different output types offer various options for temperature controllers. Time-proportional outputs are good for heating elements, while analog-proportional outputs finely tune the voltage or current for control devices. The choice of output—whether it's an electromechanical relay or a solid-state relay—can significantly impact the controller’s performance and lifespan.

CD Automation is a leader in temperature control, offering a wide range of controllers from single-zone to multi-loop setups. Our products, from top brands, combine advanced PID algorithms with easy-to-use designs, ensuring accuracy and simplicity.

CD Automation’s panel mount and DIN-rail mount controllers are versatile, providing various installation options to fit seamlessly into different systems. Devices like the REVO RT Loop Multi-Zone PID Controller highlight our focus on flexibility and customization.

Whether you need precision for one process or multiple zones, CD Automation’s single and multiloop controllers offer customized solutions. Our modular Compact DIN Rail Controller shows how integration and efficiency can manage both electric and gas loads in complex industrial settings.

Looking ahead, temperature control technology has a bright future. We can expect systems to optimize energy use while keeping precise climate conditions, especially when combined with renewable energy sources.

These advancements will improve efficiency across industries, reduce the carbon footprint of temperature control systems, and contribute to a more sustainable future.

In smart homes, AI and IoT sensors will work together to adjust temperature settings, optimizing comfort and energy use based on occupancy, weather, and even pollutants.

In the medical field, temperature control systems will be key to maintaining the safety and effectiveness of medical devices and biological samples.

Precise temperature control will be crucial for keeping these sensitive materials stable, whether in labs or during transport.

The transportation of temperature-sensitive items, like food and pharmaceuticals, will also benefit from improved temperature control technology. As cold chain logistics advance, maintaining stable temperatures during transit will become more efficient, protecting the quality and safety of perishable goods.

Temperature control technology is vital in many aspects of our modern world. From the food we eat to the cars we drive, its precision impacts our daily lives. As we explore current trends and future possibilities, it's clear that innovations in temperature control are not just enhancing today—they're building a smarter, safer, and more sustainable future.

The latest trends in temperature control technology include the integration of artificial intelligence, advanced sensors and data analytics, as well as the use of cloud computing and wireless communication. These trends are improving temperature control systems' accuracy, efficiency, and connectivity.

Potential future applications of temperature control technology include optimising climate control in smart homes and buildings, enhancing efficiency in industrial processes, maintaining the temperature of medical devices and biological samples, and improving the transportation of temperature-sensitive products. These advancements can have far-reaching benefits in various sectors.

CD Automation offers a diverse range of PID temperature controls, including panel-mount and DIN-rail-mount controllers and single- or multiloop controllers. These controllers cater to varied budgets and applications and focus on precision and ease of operation.

AI and machine learning contribute to temperature control technology by enabling systems to learn from past performance and adapt to changing conditions. This results in improved accuracy, efficiency, and predictive capabilities, which optimise energy usage and contribute to more intelligent temperature management.

Using a PID temperature controller offers the highest level of precision in temperature control by combining proportional, integral, and derivative functions. This allows for consistent and accurate temperature maintenance in demanding applications.